| Tweet |

Custom Search

|

|

|

||

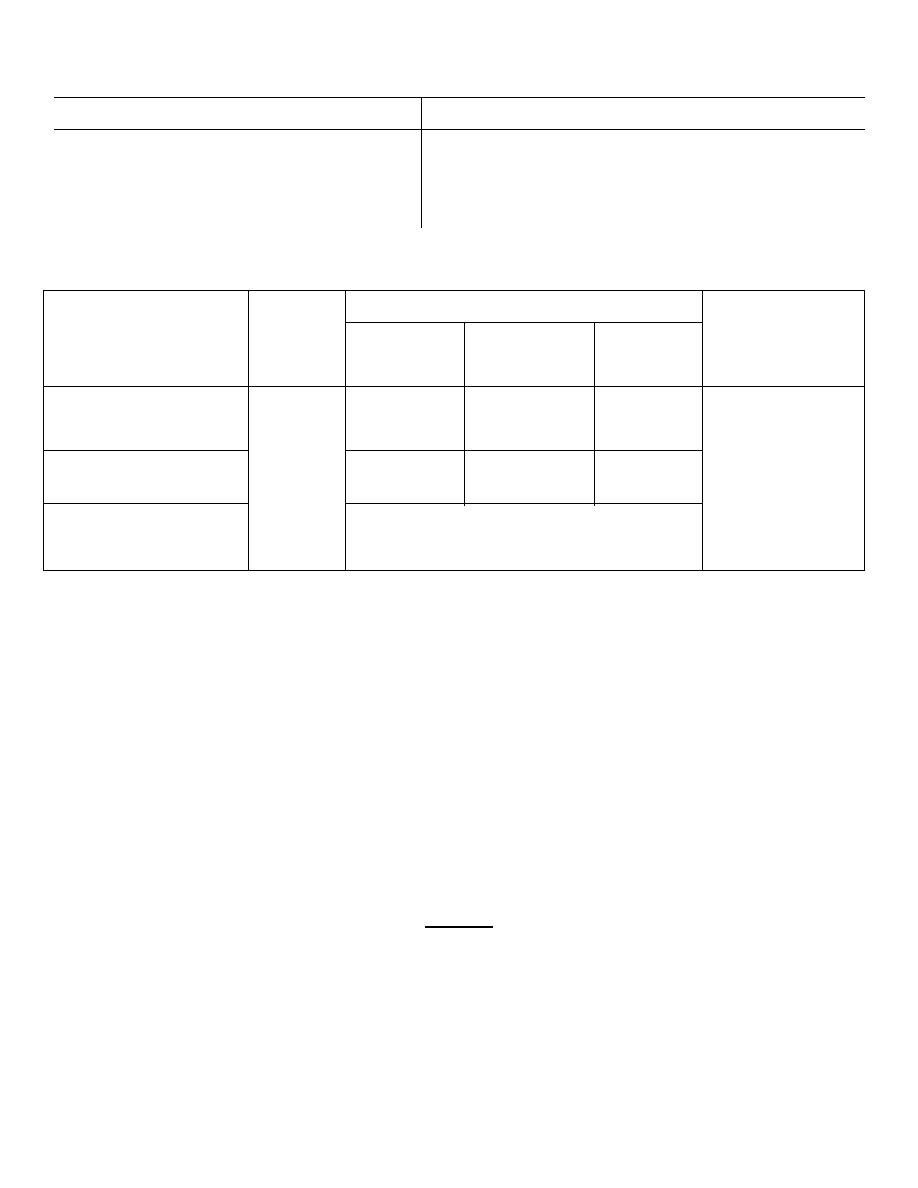

LUBRICATION ORDER

LO 55-1905-220-12

*TOTAL TASK HOURS

*TOTAL TASK HOURS

INTERVAL

TASK-HOURS

INTERVAL

TASK-HOURS

BM

0.2

Q

1.0

D

0.1

M

0.5

-KEY-

EXPECTED TEMPERATURES

CAPACITY

Above +32-F

+40Fto-10F

0Fto-65F

INTERVALS

Above 0C

+5Cto-23C

-18Ccto-54C

OE/HDO Lubricating oil,

OE/HDO30

OE/HDO10

BM - Bi-monthly

(MIL-L-21 04) engine

D - Daily

OEA Lubricating oil, ice,

As Required

OEA

(MIL-L-10295)

artic

M - Monthly

GAAGrease, automotive

All Temperatures

Q - Quarterly

(MIL-G-10924F) and artillery

NOTES

13. CHANGING TORQUE CONVERTER FLUID. Change the torque converter fluid every three months. Make certain

the winch engine is not operating. Do not drain oil into bilges; use the oil separation and recovery system to collect the

drained oil. To drain converter remove plug in bottom of turbine housing. Remove plug in reserve tank. Drain radiator.

Clean screen element in bottom of reserve tank and remove orifice assembly. Clean filter screen and hole in orifice. Install

orifice assembly and drain plug. Open vent valve on top of the turbine housing and bleed valve on top of the radiator.

Remove radiator filler cap. Add approximately 7 gallons (26.5 liters) of oil (OE/HDO) through the radiator filler opening

until fluid flows from the vent on top of the turbine housing. Close vent valve and continue filling, until the oil level reaches

the filler opening. Then close bleed valve. Tightly install filler cap to prevent leakage when operating. Remove filler cap

from reserve tank. Fill tank with approximately 3 qts (2.84 liters) of oil (OE/HDO), to one inch below the full mark on dip

stick. Install filler cap, start engine and operate at half throttle. Check all fittings for leaks. Check pressure gage for

operating pressure. Normal operating pressure is 45 to 65 PSI, and fluid temperature is under 200OF when converter is

properly filled and vented. The pressure gage responds instantly to full pressure upon starting engine and zero pressure

upon stopping. Sluggishness indicates air trapped within unit requiring further venting at the high point bleed valve. At

part-throttle operation, check reserve tank oil level frequently to ensure adequate fluid level. Add fluid as required.

14. DRY TYPE AIR CLEANER. Clean air cleaner element with compressed air every two months, and replace annually.

CAUTION

Air pressure at nozzle of air hose must not exceed 100 PSI.

Inspect cleaned element. If thin spots, pin holes or rupture is found, replace element.

Card 15 of 27

|

||

|

||