| Tweet |

Custom Search

|

|

|

||

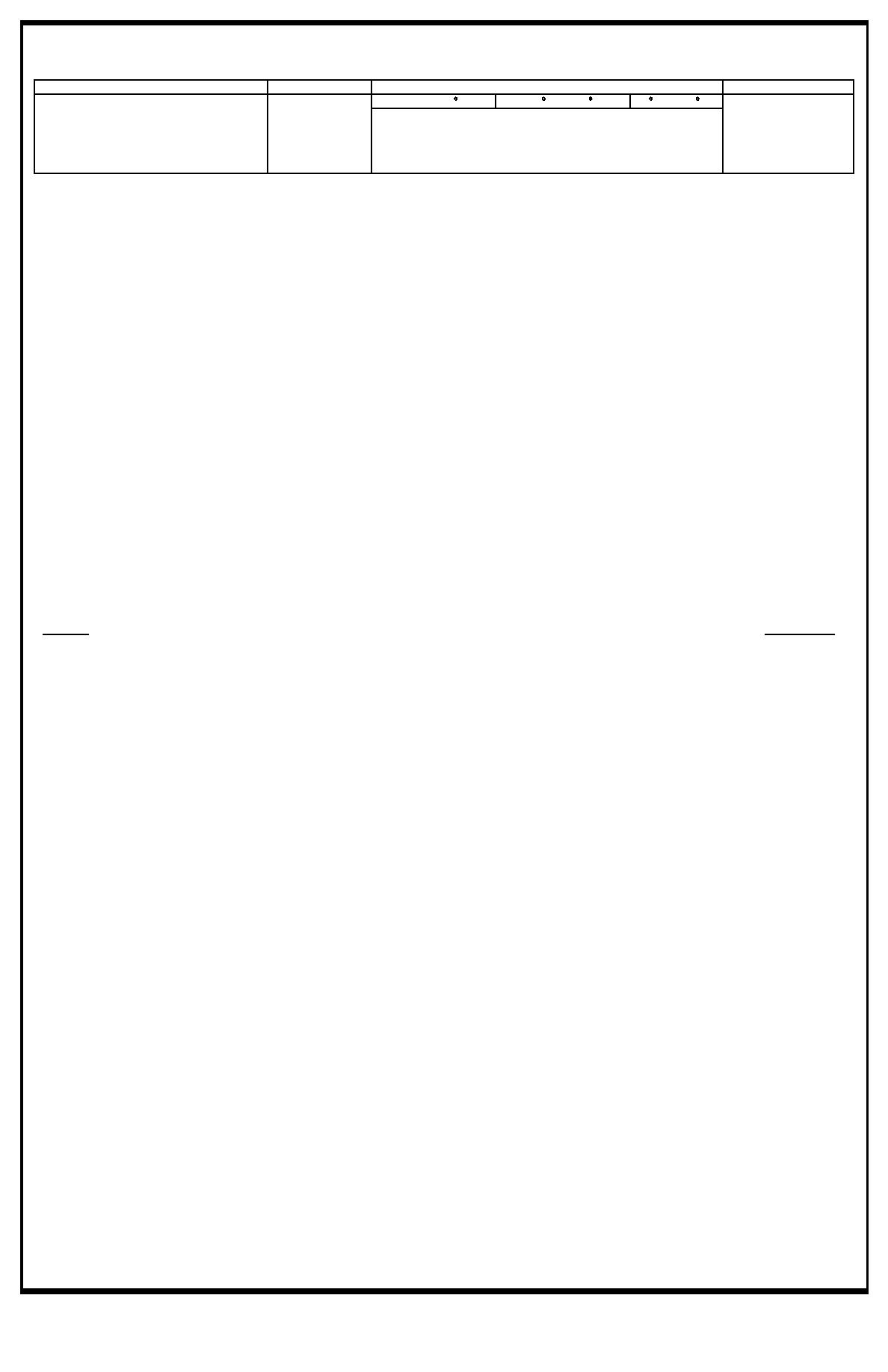

-KEY-

CAPACITY

EXPECTED TEMPERATURES

INTERVALS

Above +32 F

+40 F to -10 F

0 F to -65 F

Intervals

given are

GAA-GREASE, Auto & Artillery

ALL TEMPERATURES

in hours of

normal

operation

NOTES:

1. ROTARY PUMP, is furnished with prepacked ball bearings which will normally require no attention before or after being placed in operation. If the pump

should be disassembled for may reason, repack the bearing with GAA Grease before reassembling the pump.

2. COUPLING. The coupling is of the Jaw Type. Each coupling hub is keyed to the shaft to prevent rotation and is secured by a set screw. Since there are no

moving parts, no lubrication is required.

3. GREASE DRAIN PLUG. If motors are stored for more than three months, the plugs at the bottom of the bearing chambers should be removed and a portion

of the lubricant drained. Replenish with an equivalent amount of Grease after the drain plugs have been replaced. When motor is in daily operation remove

drain plugs and supply 2 or 3 shots of GAA Grease every 200 hrs at grease fittings. Replace drain plug.

4. LUBRICANTS. The following is a list of lubricants with the Military Symbols and applicable Specification numbers. GAA MIL-G-10924.

Copy of this Lubrication Order will remain with the equipment at all times; instructions contained herein are mandatory.

BY ORDER OF THE SECRETARY OF THE ARMY:

CREIGHTON W. ABRAMS

General, United States Army

Chief of Staff

VERNE L. BOWERS

Major General, United States Army

The Adjutant General.

DISTRIBUTION: To be distributed in accordance with DA Form 12-25D (qty rqr block No. 813)

Operator' Maintenance requirements for marine Equipment All.

s

FOLD

FOLD

*U.S. GOVERNMENT PRINTING OFFICE: 1973 O-520-035

LO55-1925-204-12-8

|

||

|

||