| Tweet |

Custom Search

|

|

|

||

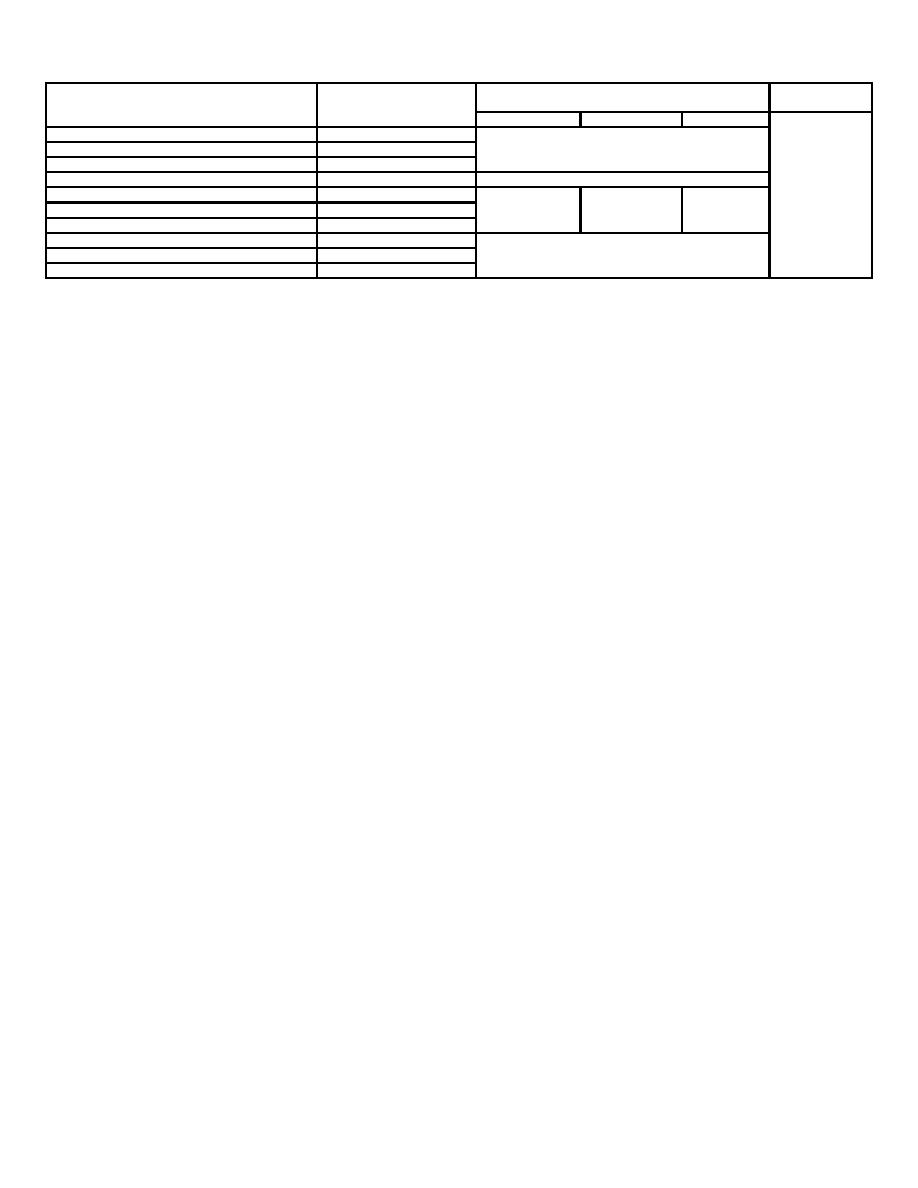

KEY

LUBRICANTS

CAPACITY

EXPECTED TEMPERATURES

INTERVALS

Above +32

F

+40 to -10

F

F

0 to -65

F

F

OE-OIL, Engine, Heavy Duty

OE 10

Spare Lube Oil Tanks 2 ea.

120 qt

Lubricator Cargo Well Pump

4qt ea

Intervals

Spare Lube Oil Tank 2 ea.

120 qt

OE 30

given are in

Hydraulic Oil Tank

300 gal

OE 10

hours of

Oil Can Points

OE 30

OE 10

OES

normal

OES-OIL, Engine, Sub-zero

operation

WTR-GREASE, Aircraft General Purpose

Wheel Spindle Grease Retainer 4 ea.

3.4 lbs ea

ALL TEMPERATURES

GAA-GREASE, Automotive and Artillery

NOTES:

7. OIL CAN POINTS. Every 50 hours lubricate scuttle covers hinges

and dog bolts; sliding hatch rails and dog latches on hulls 5 through 18;

1. FOR OPERATION OF EQIPMENT IN PROTRACTED COLD

engine compartment hatch hinges and brace assembly; winch control and

TEMPERATURES BELOW - 10 . Remove lubricants prescribed in the

F

brake levers; winch knob clutch handle; search light shaft; drivers seat

key for temperatures above - 10 . Relubricate with lubricants specified

F

controls; brake and throttle controls governor shaft; ramp latch and ramp

in the key for temperatures below - 10 .

F

control valve; emergency stop on engine; throttle linkage on engine; cab

steering lever lock, cab window and door, hinges and latch; bilge pump

2. HATCH DOG. There are two dogs for each machinery hatch cover

controls; tire inflation valve; fan controls; and the follow-up rod ball joints

and five machinery hatch covers for each side of hulls 19 through 60. (for

with OE.

hulls 5 through 18. See note 7)

3. RAMP HINGES. Grease daily with WTR. On hulls 6, 8, 16, 17 and

8. WHEEL SEALS AND WHEEL COLUMN SUPPORT BEARING.

19 through 60, ramp must be raised to lube fitting installed in end of each

Lubricate after each water operation with WTR. After operation in salt

ramp hinge pin. All others will be greased by lowering ramp to gain

water, hose with fresh water if available amid relubricate.

access to lube fittings installed in top of each ramp hinge.

8a. WHEEL SPINDLE GREASE RETAINER. After each water

4. RADIATOR FANS. FAN IS NOT LUBRICATED. However, grease is

operation fill retainer with STR Grease. Retainer must be kept filled with

applied at center of motor shaft, only to keep water from entering motor

grease at all times.

bearing area.

9. PROPELLER STRUT BUSHINGS. Every 10 hours and after each

5. RUDDER STOCK BUSHING. Every 10 hours lubricate with WTR.

amphibious operation lubricated with WTR. When water based, lubricate

bushing each watch.

6. RUDDER CONTROL CABLE. Every 50 hours cleans and coat

cables with CE oil.

10. LUBRICANTS. The following is a list of lubricants with the Military

Symbols and applicable specification numbers.

OE MIL-L-2104

GAA MIL-G-10924

OES MIL-L-10295

WTR MIL-G-81322

TS015526

Card 2 of 10

|

||

|

||