| Tweet |

Custom Search

|

|

|

||

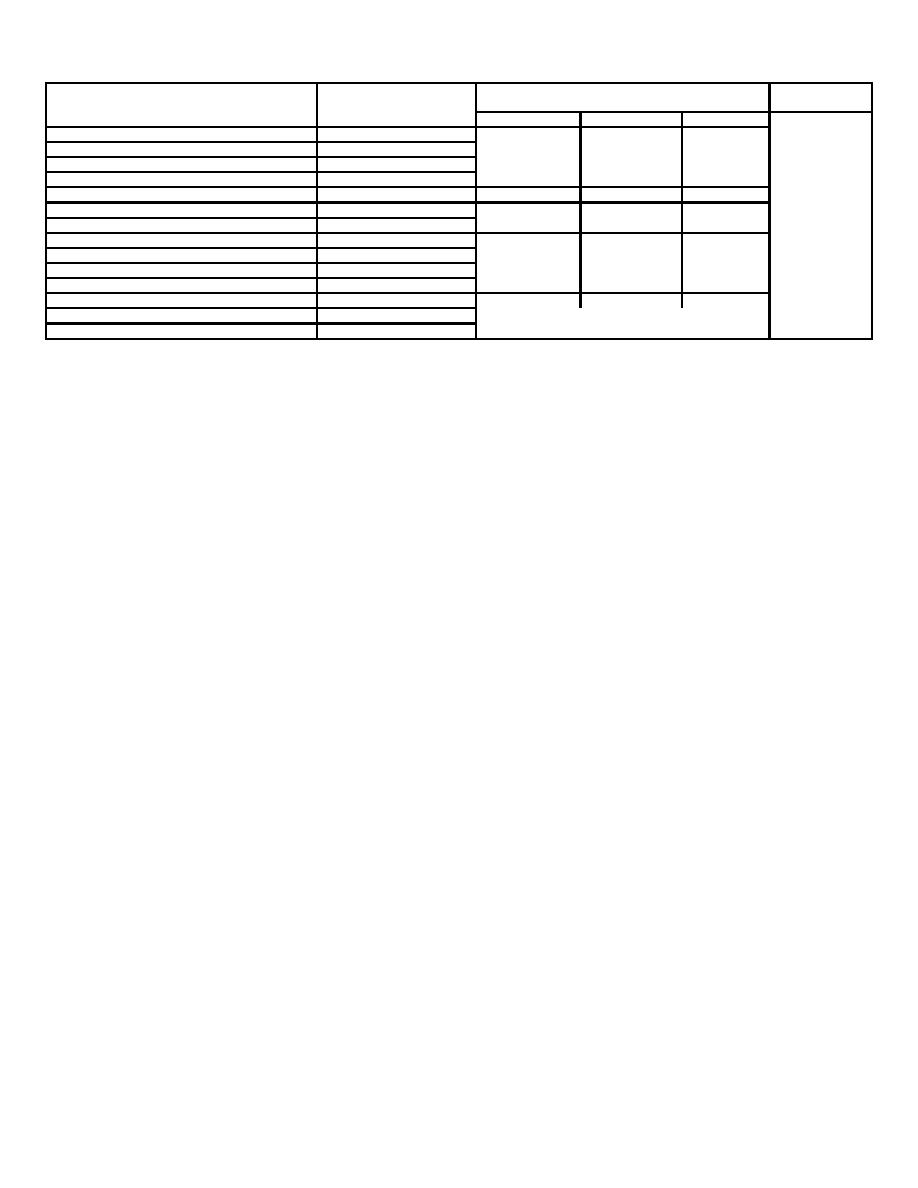

KEY

LUBRICANTS

CAPACITY

EXPECTED TEMPERATURES

INTERVALS

Above +32

F

+40 to -10

F

F

0 to -65

F

F

OE-Oil, Engine, Heavy Duty

Crankcase 4 ea

20 qt ea

OE 30

OE 10

OE 10

Air Cleaner

AR

Intervals

Oil Can Points

given are in

Gathering Box 2 ea

12 qt ea

OE 30

OE 30

OE 10

hours of

Transmission-Torque converter 4 ea

52 qt ea

OE 10

OE 10

OES

normal

Fluid Coupling 4 ea

20 qt ea

operation

OES-Oil, Engine, Sub-zero

GO-LUBRICATING OIL, Gear

GO 90

GO 80

GOS

Miter Box 4 ea

15 qt ea

GOS-LUBRICATING OIL, Gear, Sub-zero

9170 LUBRICATING OIL, Engine

GLA-GREASE, General Purpose

ALL TEMPERATURES

GAA-GREASE, Automotive and Artillery

NOTES:

1.

8. TACHOMETER CABLE. Every 1000 hours, completely disassemble,

FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD

clean, and lubricate lightly with GAA grease on hulls 5 through 29.

TEMPERATURES BELOW - 10 . Remove lubricants prescribed in the

F

key for temperatures above - 10 . Relubricate with lubricants specified

F

in the key for temperatures below -10 .

F

9. GATHERING BOX. Every 10 hours, check oil level. Every 500 hours

drain gearcase, oil cooler and lines. Replace drain plugs and lines. Refill

2. OIL CAN POINTS. Every 50 hours, lubricate governor shaft

gathering box gearcase with OE. Run engine for 5 minutes, check for

emergency stop on engine, throttle linkage and all exposed adjusting

leaks, check oil level and bring to full mark.

threads with OE.

3. FLEXIBLE COUPLING. Every 50 hours lubricate with GLA grease.

10. AIR STARTING MOTOR MODEL A31RH. Grease fitting in housing

Prior to installation, disassemble, clean and hand pack coupling.

cover receives two shots GAA grease from hand gun. Grease fitting in

gear case receives 20-30 shots GAA grease from hand gun.

4. FLUID COUPLING. Every 2000 hours, rotate coupling until fill, level

and drain plug is located at bottom and drain. Rotate coupling until fill

plug is at 50 degrees from vertical position to allow necessary air space.

AIR STARTING MOTOR MODEL B21 RH. Remove any one of the three

Fill with OE.

oil plugs in the housing cover, fill the oil chamber with 9170 oil. Grease

fitting in the gearcase receives two shots GAA grease from hand gun.

5. TRANSMISSION-TORQUE CONVERTER AND STRAINER. Every

10 hours, check oil level with engine running and transmission at

operating temperature. Every 500 hours remove drain plug and strainer

11. STEADY REST BEARING. Every 1000 hours remove bearing cap

from transmission. To drain torque converter remove inline hose. Start

and remove as much of the old grease as possible. Hand pack the

engine and run at 1000 rpm. CAUTION: Do not run engine longer than

bearing, and lower half of the bearing housing with GLA grease. Replace

30 seconds. Clean oil strainer. Reinstall drain plug, strainer and

bearing cap.

converter inline hose. Fill transmission with OE. Run engine for 5

minutes, check for leaks. Check oil level and bring to full mark.

12. LUBRICANTS. The following is a list of lubricants with the Military

6. OIL FILTERS. Every 200 hours remove filter elements, clean

Symbols and applicable specifications numbers.

housings, install new elements, fill crankcase, operate for 5 minutes,

check for leaks, check crankcase oil level, and bring to full mark.

OE MIL-L-2104

OES MIL-L-10295

GO MIL-L-2105

GOS MIL-L-10324

7. AIR CLEANERS. Every 50 hours, refill reservoir to level mark. Every

GAA MIL-G-10924

9170 MIL-L-9000

200 hours disassemble entire units, clean, reoil and reassemble.

GLA MIL-G-23549

TS 015532

Card 8 of 10

|

||

|

||