| Tweet |

Custom Search

|

|

|

||

more rapidly than those in the center of the vessel Therefore, spot replacement of certain anodes may be

required from time-to-time without the expense of complete replacement of the system. As general

criteria, anodes should always be replaced when they are approximately 50 percent or more deteriorated.

(3) Anodes shall conform to Sacrificial Zinc Alloy Anode, type ZHC. The lower driving potential and

current limiting characteristics, when providing protection to a steel surface, are desirable properties.

Although zinc anodes do not require dielectric shields, zinc should not be installed over a bare steel hull.

The same coating system that is used to coat the hull should be applied beneath the zinc anodes to act

as a barrier. Proper functioning of the anode depends upon complete immersion in seawater, a clean

anode surface, and a positive contact between the anode and the surface requiring protection. Anodes

shall not be attached to propellers, propeller shafts, strut arms, strut barrels, or on the exterior of the stern

or strut tube fairwaters.

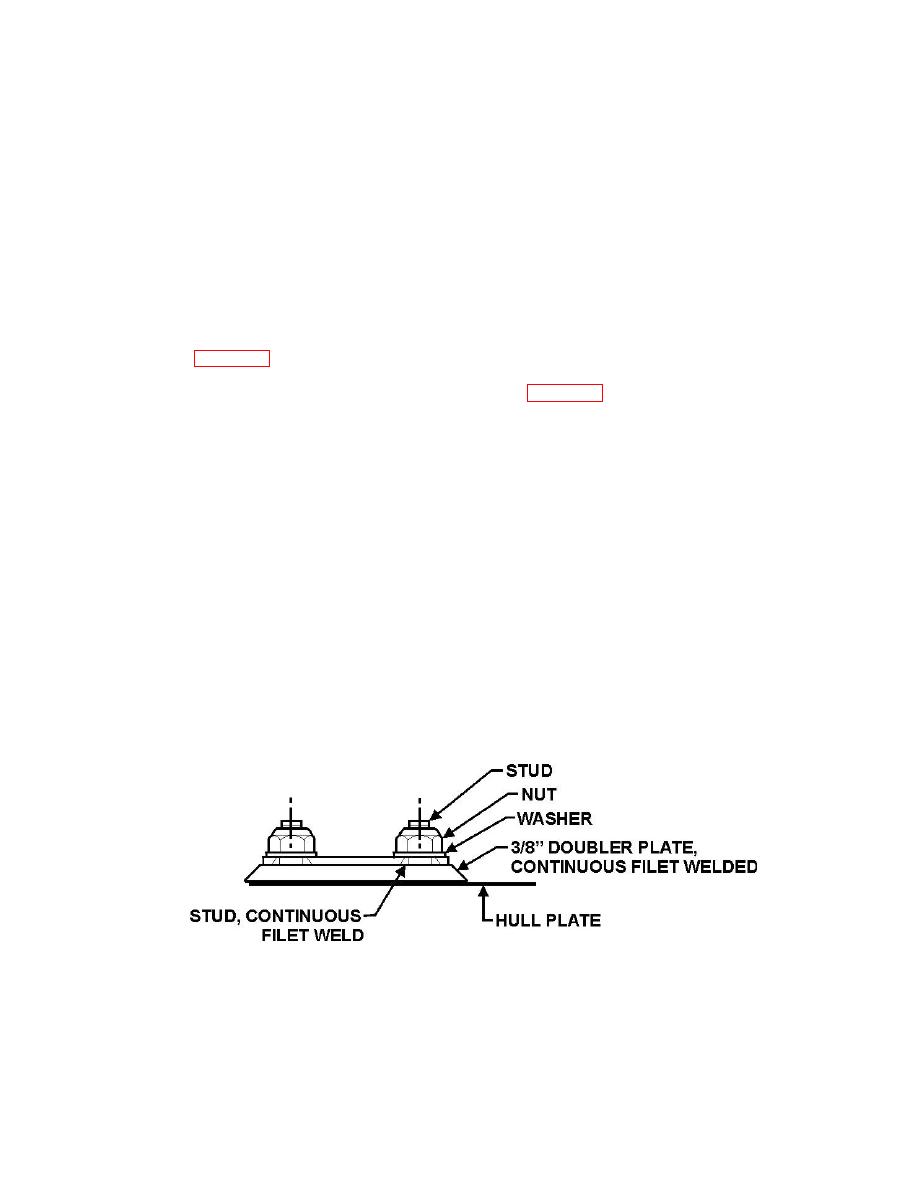

(4) Anodes shall be attached to the hull by the bolt-on method to facilitate replacement. A doubler

plate, as per figure 1-1 will be installed. The attaching studs will be welded to the doubler plate. The

doubler plate, stud, washer and nut will be made of corrosion resistant steel (CRES). Stud location and

anode strap drilling will be determined using the information in Figure 1-2. Prior to anode installation, the

stud will be cleaned to remove all paint, rust or other matter to insure a positive contact between it and

the anode strap. After installation of the anode, the nut, stud and washer will have the same coating

system applied as the hull. The stud can be cut off flush with the top of the nut to minimize turbulence in

service.

(5) Occasionally, a zinc anode may develop an oxide film, which renders it inactive. Although this is

the exception rather than the rule, this inactive state can readily be detected by comparing the anode with

others in the system. The inactive anode usually will have a hard to remove, dark grey or black film on the

surface, however, the anode manufacturer's identification will still be prominent; such anodes should be

replaced. A light colored soft deposit on the surface, even though quite thick, is normal and may be

prevalent under conditions of low velocity.

(6) The quantity of anodes specified for the hull shall be installed. The hull surface beneath the zinc

should be properly coated with the complete anti-corrosive system specified for the hull. Areas blistered

from welding shall be painted the same as the hull.

CAUTION

Do not paint the zinc anode surface, this will insulate the anode and stop the flow of current. Only

use specified steel for studs, deviation from this would cause deterioration of the hull.

(a) 3/8 " doubler plate, stud, washer and nut will be made of corrosion resistant steel (CRES).

(b) Stud for ZHC is 5/8" diameter.

(c) Doubler plate for ZHC to be 3/8" (T) x 6" (W) x 12" (L)

|

||

|

||