| Tweet |

Custom Search

|

|

|

||

TB 55-1900-201-45/1

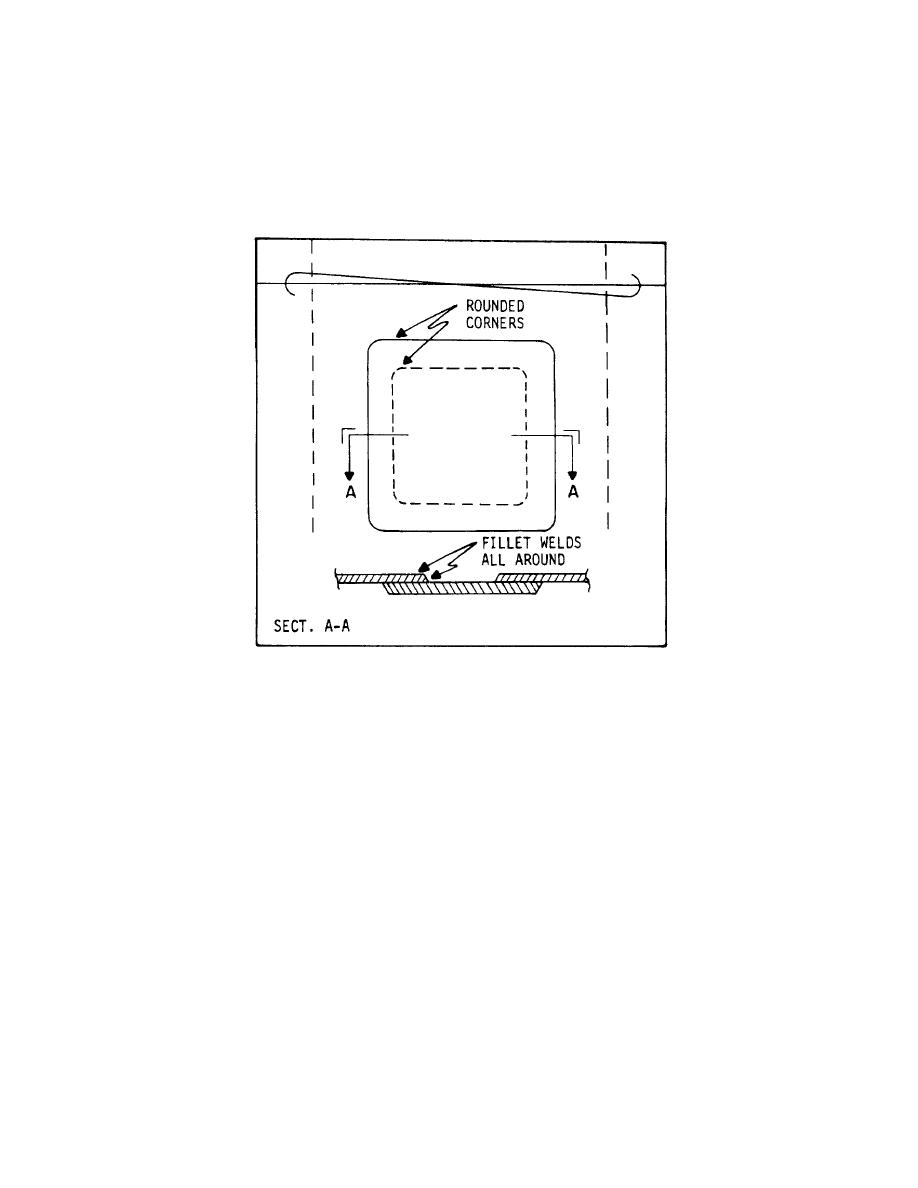

patch is at least as good as would be required if an insert were used. If the opening required to achieve this exceeds that

appropriate to the use of a patch plate, an insert plate should be used. Patch plates should be continuously fillet welded

both inside and outside. In order to reduce heavy stress concentrations in the vicinity of patch plates, such plates and

the holes which they cover should have their corners rounded to a radius at least equal to one eighth of their transverse

dimension or three inches whichever is the greater.

Method of Installing a Patch Plate

E-26. Welded Doubler Plates.

a. A welded doubler plate is not, in general, considered suit- able as a permanent repair measure for the main hull

girder. Its use does not insure continuity of strength which is achieved by the installation of an insert plate in the same

location. Also, when a doubler is attached to deficient plating, its very presence creates a discontinuity which may induce

rather than prevent a structural failure. Additionally, where doublers have been used, they tend to proliferate as ran-

domly-placed patches which often serve only to cover up the deficiencies which would otherwise indicate the true condi-

tion of the hull.

b. Doublers may properly be used to provide local reinforcement at hatch corners, overboard discharge, searchests,

mast or kingpost foundations, etc. They may also be used in accordance with approved

E-18

|

||

|

||