| Tweet |

Custom Search

|

|

|

||

TB 55-1900-232-10

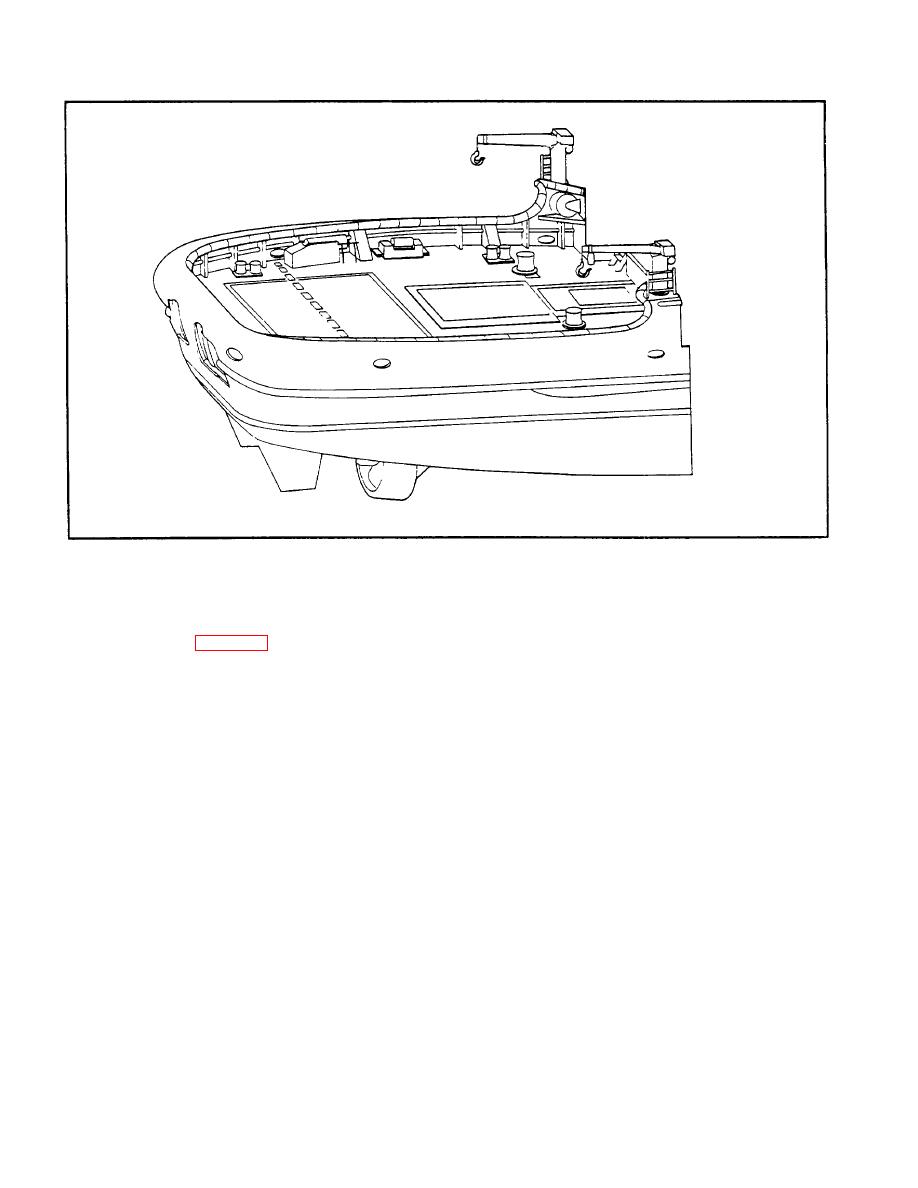

Figure 2-40. Bulwark Forward Limits.

(Text continued from page 2-45)

or "stretchability." In many cases, this high elasticity was why the material was selected. The primary materials used in

these tensile members are wire rope, natural fiber line, synthetic fiber lines, chain and connecting fittings.

24-.1 WIRE ROPE. Prior to the development of wire rope, the primary tensile member for mooring and towing was

natural fiber line made from such fibers as manila, sisal and hemp. As ships became larger, the loads increased and the

diameter of natural fiber lines also increased. This increase occurred to the extent that the lines became too large and

heavy to handle easily by manpower and also too large to store easily in the lengths required for towing. During the 19th

century, wire rope was developed. Because of its superior abrasion resistance and strength-to-weight and strength-to-

size ratios, it rapidly replaced fiber lines for towing hawsers. Acceptance of wire rope for towing occurred despite the fact

that its elasticity was far less than that of fiber lines. At first, loss of elasticity was countered by the use of long spans of

hawser, where the weight of the wire rope formed a catenary in the wire and provided a measure of effective elasticity.

Later, ocean and coastal tows often used manila spring pendants, or "springs," in conjunction with wire rope to provide

the needed elasticity. Other efforts to provide wire rope with sufficient stretch included the development of a "spring-lay"

rope. The composite rope was a combination of wire and natural fiber. This early composite concept was not unlike

present-day efforts to marry other synthetics and Kevlar. Kevlar has a modulus of elasticity of approximately the same

value as steel.

2-50

|

||

|

||