| Tweet |

Custom Search

|

|

|

||

TB 740-97-4

(b) Compression-ignition

engines operating at output levels of 150 psi ( bmep ) and above. At the beginning of

engine preservation, the engine crankcase, and the crankcases of any mounted accessories having a separate crankcase from the

engine, will be filled to the operating level with P-10 preservative lubricating oil, type II, grade 10 or 30 as applicable. Upon

completion of engine preservation, the preservative oil will remain in the crankcases. A tag will be prepared for each crankcase

indicating "THIS CRANKCASE IF FILLED TO THE OPERATING LEVEL WITH PRESERVATIVE LUBRICATING OIL GOOD FOR

OPERATION UNTIL THE FIRST REQUIRED LUBRICANT CHANGE-DO NOT DRAIN-CHECK OIL LEVEL IF LOW FILL TO THE

OPERATING LEVEL WITH THE OPERATING OIL (MILL-2104) APPLICABLE GRADE." The tag will be attached to the crankcase fill

tubes.

(2) Dry sump.

(a) Crankcases of air-cooled engines that are lubricated by adding lubricating oil to the fuel, P-10 preservative

lubricating oil, type I, grade 10, 30 or 50 as applicable, will be added to the fuel in the ratio specified for normal operation. The

engine will be started and operated at fast idle until running smoothly. The engine will then be accelerated to 3/ speed, without load,

to assure coverage to all interior surfaces of the lubricating system.

(b) Air cooled dry sump engines which operate with no oil in the crankcase, the inspection plate, air box cover or the

plugs will be removed from the bottom of the crankcase and the entire interior of the crankcase will be sprayed with P-10 preservative

lubricating oil, type I, grade 30, while rotating the engine crankshaft for at least three complete revolutions.

c. Cooling Systems Cooling systems including all tanks, pumps, pipes, water jackets, keel cooler and heat exchangers will be

drained. Thoroughly examine the system for faulty gaskets, rubber hoses, leaks, rust, dirt, loose connections and evidence of oil

seepage into the system. Systems will be cleaned and preserved as follows:

(1) Fresh water systems. Fresh water cooling systems will be cleaned using cleaning compound conforming to MIL-C-

10597. Cleaned systems will be filled with a clean solution of equal parts by volume of ethylene glycol and water or arctic type

antifreeze in accordance with table 1. To determine the percent of antifreeze required, it is necessary to consider the area where the

item is being stored or shipped. The depreservation guide will be annotated to indicate the antifreeze and percentage thereof which

the cooling systems contains.

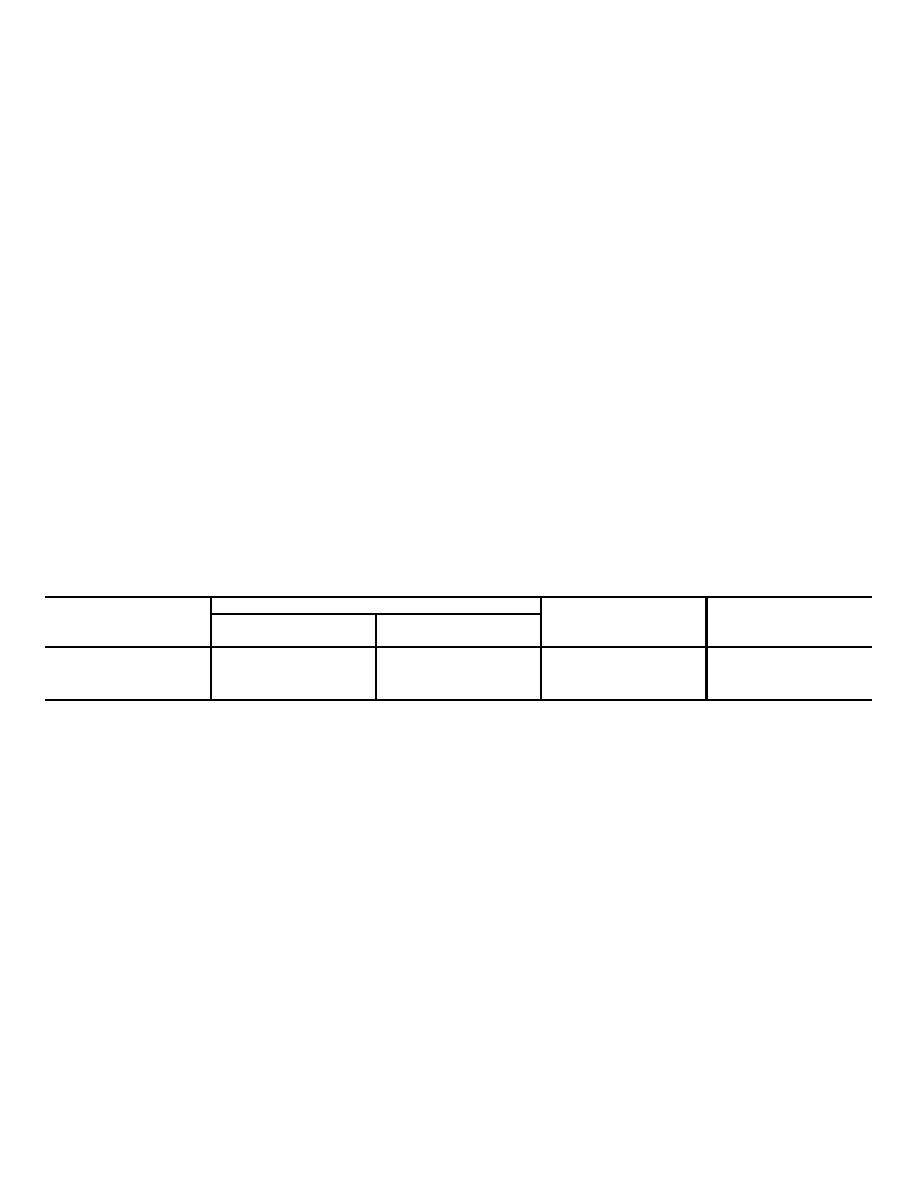

Table 2. Guide for Protecting Cooling Systems

Lowest est.

Percent of

temp in

Geographic area

Antifreeze

Water

Specification

Notes

50

50

MIL-A-46153

1

-30 .

F

60

40

MIL-A-46153

1

-30 to -55 .

F

100

0

MIL-A-11755

2

below -55 .

F

NOTE 1

Antifreeze conforming to A-A-548, type 1, may be used provided one ounce of corrosion inhibitor conforming to O-I-

490 is added for each two quarts of water used in the solution.

NOTE 2

The antifreeze compound will be used without dilution.

(2) Raw water system. Raw water cooling systems will be flushed with clean fresh water and blown dry with dry

compressed air. The system will then be flushed with preservative conforming to MIL-C-16173, grade 5, and then thoroughly drained.

NOTE

The drained grade 5 preservative may be used to preserve additional engines until it shows evidence of

contamination by visible change of color, presence of rust particles and/or other foreign contamination. The presence

of rust particles and other foreign contaminates can be detected by filtering a small amount of the drained compound

through a suitable filter paper.

d. Fuel Systems.

(1) Spark ignition gasoline engines.

(a) Engines with carburetors. A portable container with two compartments will be

4-2

|

||

|

||