| Tweet |

Custom Search

|

|

|

||

TM 5-1940-277-20

TM 1940-20/2

Table 2-1. Unit Preventive Maintenance Checks and Services (cont)

W-Weekly

Q-Quarterly

S-Semiannually

Item to be inspected

Interval

Procedure: Check for and have repaired, filed,

Item

or adjusted as needed

No.

S Item

Perform all operator PMCS first

WQ

2

(Cont)

7

6

8

MK2 WITH CUMMINS ENGINE

NOTE

The MK II with Cummins engines does not utilize raw

water pumps. Raw water is supplied by the hydrojet unit to

cool the transmission oil cooler and engine exhaust gases

only. All other watercooling is provided within a closed

system through a belt driven circulating pump on each

engine.

c.

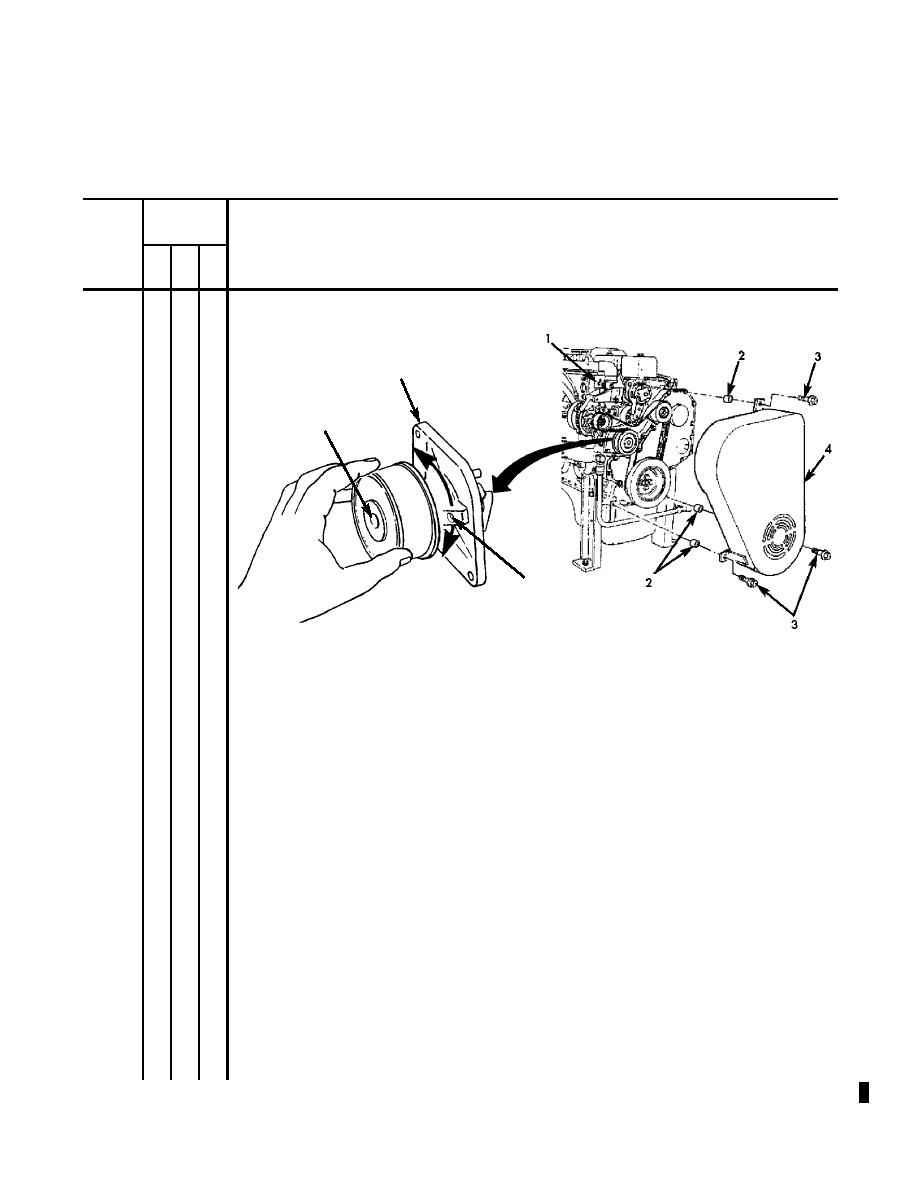

Remove three screws (3), spacers (2), and protective cover (4) from front of

each engine (1).

d.

Using suitable 1/2-in. (13-mm) drive wrench, rotate belt tensioner (5) to the

right to release tension on serpentine belt, and inspect for free rotation of

water pump impeller shaft (6). Shaft (6) should rotate without binding or

excessive looseness. If binding or loose, replace water pump (7).

e.

Inspect weep hole (8) for evidence of a leaking seal. If leaking is evident,

replace water pump (7).

NOTE

Prior to installing protective covers, it will save time to

perform PMCS. Item No. 8 to check condition of serpentine

belts and tensioners.

f.

Install protective cover (4) on front of each engine (1) with three spacers (2)

and screws (3).

Change 2

2-4.1/(2-4.2 blank)

|

||

|

||