| Tweet |

Custom Search

|

|

|

||

TM 5-2805-261-13

LOCATION/ITEM

ACTION

REMARKS

4-24. FUEL TANK INSPECTION/TEST - continued

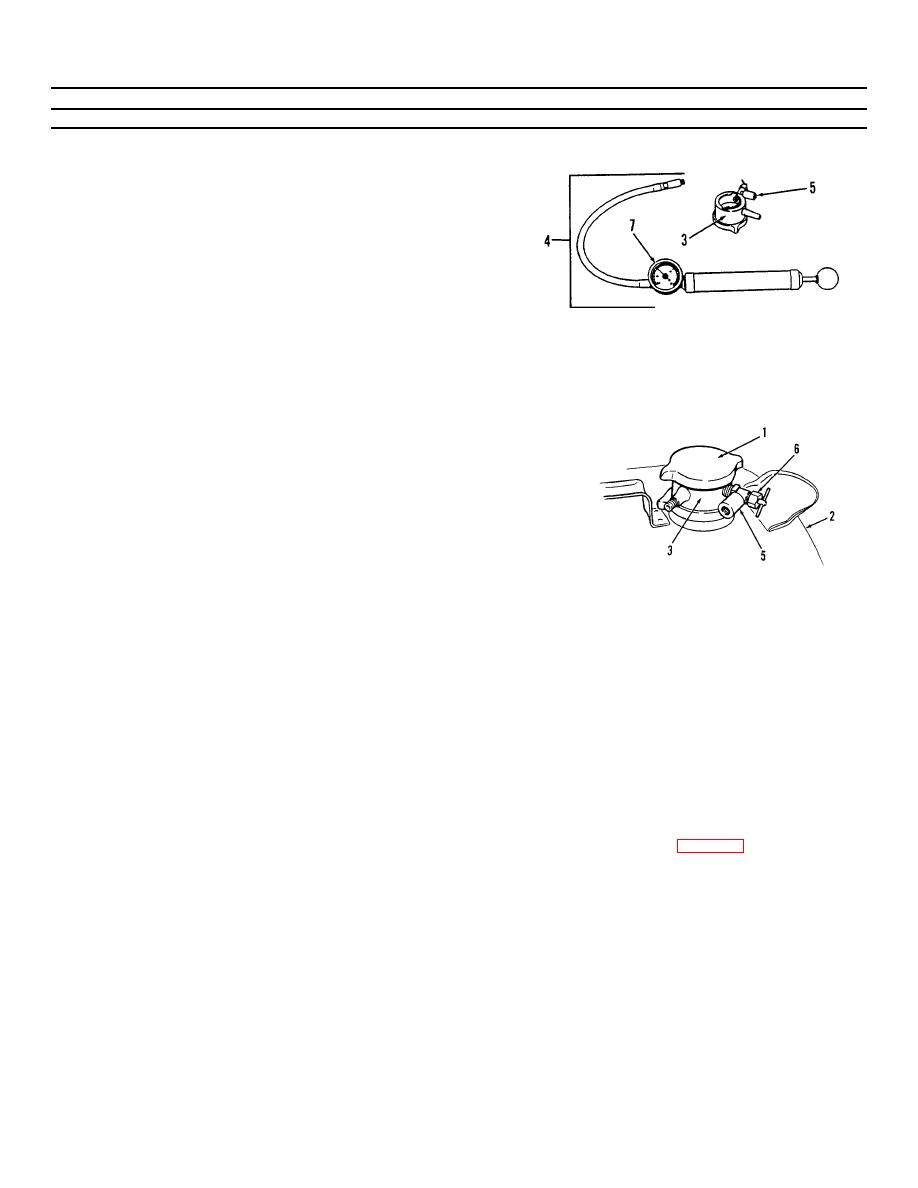

5. Pressure tester (4)

Screw into fitting (5) on

adapter.

6. Air release valve (6)

Open.

NOTE

Pump pressure tester in short

bursts. This will minimize

the chance of over-pressurizing.

Figure 4-21. S34 pressure tester

Over-pressurizing will perma-

nently damage the tank.

7. Pressure tester (4)

Pump until pressure gage (7)

reads 10 psi (69 kPa).

8. Fuel hose

Hold end in container and

depress ball check valve

to expel any remaining

fuel.

9. Pressure tester

Pump until air is back up

to 10 psi (69 kPa).

10. Air release valve (6)

Close.

Figure 4-22. Pressure tester adapter

11. Pressure tester

Remove.

12. Fuel tank

Submerge in water and

Check all areas of tank carefully.

check for air leaks.

NOTE

Any air bubbles indicate a leak

point and the tank must be

replaced.

13. Fuel hose

Disconnect from tank.

14. Fuel connector

Submerge in water and

If assembly leaks, replace it. (See para 4-25.)

assembly

check for leaks.

15. Release valve (6)

Open and relieve pressure

in tank.

4-35

|

||

|

||