| Tweet |

Custom Search

|

|

|

||

TM 5-2805-261-13

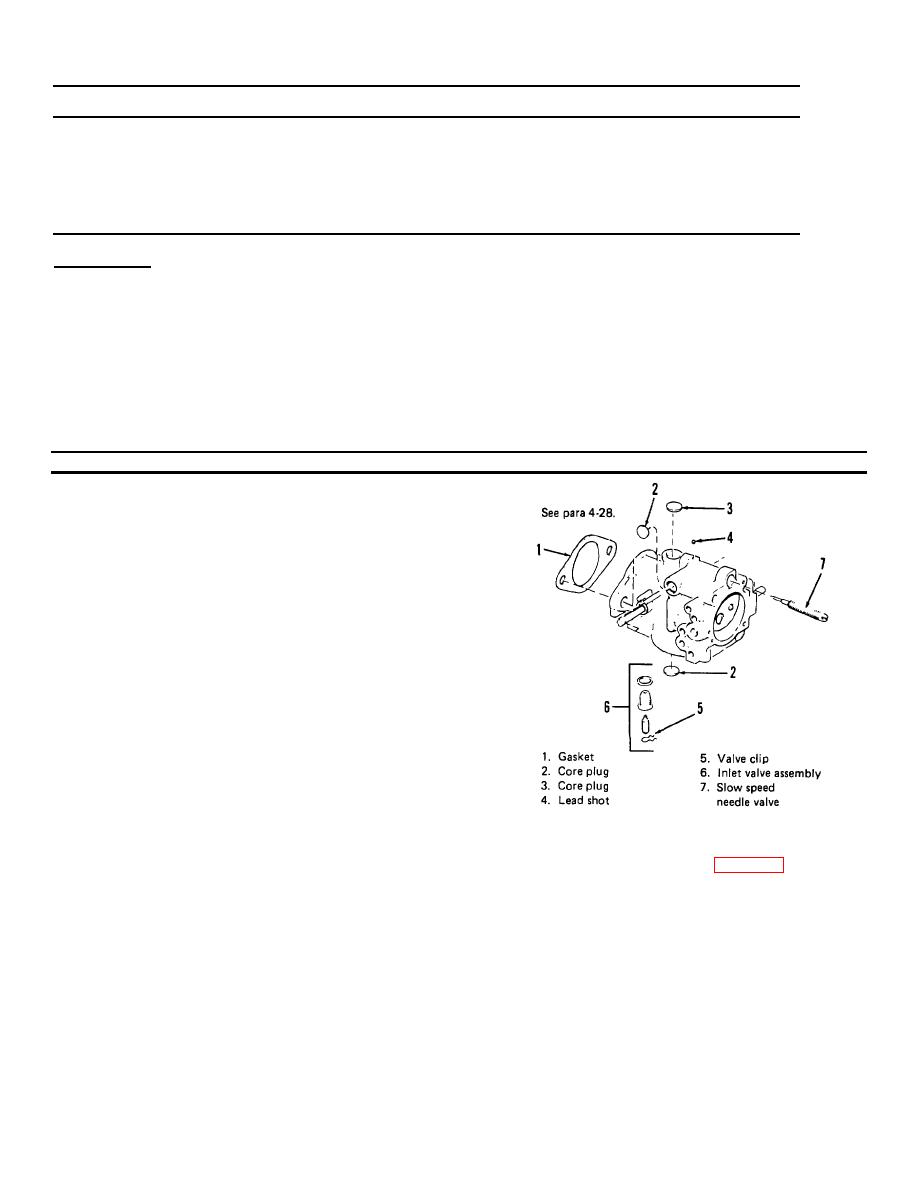

4-27. CARBURETOR MAINTENANCE

This task covers:

a. Carburetor inspection and cleaning

b. This procedure includes needle valve inspection and replacement

INITIAL SETUP :

Tools:

Equipment Condition:

Flat end center punch

Motor OFF

T6 325043

Materials/Parts:

As required

Personnel Required:

Approximate Time Required (minutes):

1 Mechanic

60

LOCATION/ITEM

ACTION

REMARKS

INSPECTION

1. Gasket (1)

Check for leaks. Replace if

necessary.

2. Core plugs (2) and (3)

Check for leaks. If leaks

are found:

a. A smart tap with a

hammer and a flat end

center punch in the

center of the core plug

will usually stop leaks.

b. If leaks persist, drill a

hole in core plug (no

more than 0.059 in.

(1.5mm) below surface)

and pry out.

CORE PLUG

Figure 4-25. Carburetor and needle valves

REPLACEMENT

1.

Casting opening

Inspect for damage.

Replace carburetor if damaged. (See para 4-28.)

2.

Adhesive

Apply to edge of core

plug (2) and (3).

4-42

|

||

|

||