| Tweet |

Custom Search

|

|

|

||

TM 5-2805-261-13

LOCATION/ITEM

ACTION

REMARKS

5-10. CRANKSHAFT AND PISTONS DISASSEMBLY/ASSEMBLY - continued

ASSEMBLY

8.

Pistons (21)

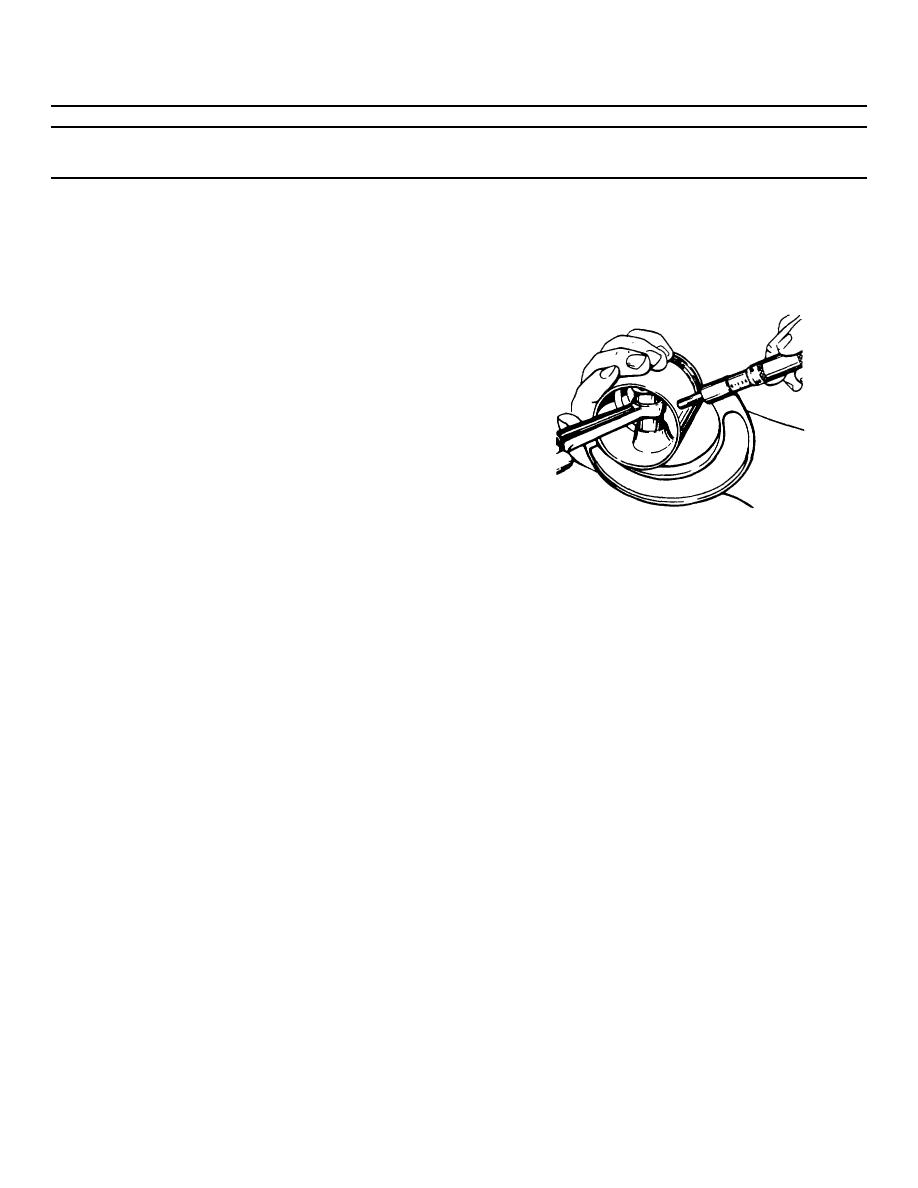

Check with micrometer to

MICROMETER CHECK

see if piston has become

distorted during assembly.

Take micrometer readings of the outside diameter of

Take two readings, 90apart.

the pistons at the bottom (skirt).

9.

Pistons (21)

Replace if the variation in

the readings at the skirt

are greater than 0.0025 in.

(0.0064 cm).

CAUTION

Be sure rings fit freely. Be

sure the retaining pin in the

piston groove is in the center

of the piston ring gap.

10. Piston rings (15)

Install on pistons.

11. "O" ring (10)

Slide on to crankshaft (22).

12. Seal (8)

Install.

Figure 5-19. Micrometer check of pistons

13. Bearing (9)

Slide on to crankshaft (22).

14. "O" ring (7)

Install in crankshaft (22).

15. Bearing (6)

Press on to crankshaft (22).

16. Snap ring (5)

Install in groove behind

Use snap ring tool no. 303859.

bearing (6).

17. Seals (4)

Install back-to-back in

crankcase head (2).

18. "O" ring (3)

Install in groove in crank-

case head (2).

5-34

|

||

|

||