| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

ing surfaces (journal bearing areas). The longitudinal line

connecting the lowest extrermities of all shafting journals

having the same diameter should form a continuous-

faired line when the machinery is at operating

temperature. When the shafting is correctly aligned at

rest, the bottoms of the shaft journals should be in

contact with the bearing material. The bearing clearance

at the horizontal centerline of the journal should be

equally divided.

(3) In order to obtain and maintain acceptable

alignment, the fundamentals of longe-stablished and

good practice are as follows:

(a) Each bearing shall guide and support its

proportinate share of the shafting weight and load.

(b

When shaft couplings are broken, each

overhanging shaft length will deflect from the true shaft

centerline, depending upon the amount of overhanging

shaft weight, the loading, -and the location of the bearing

supports.

(c) Alignment of sag charts have been prepared for

most vessels showing relative flange positions and the

angular slopes of shafting when the coupling 'bolts have

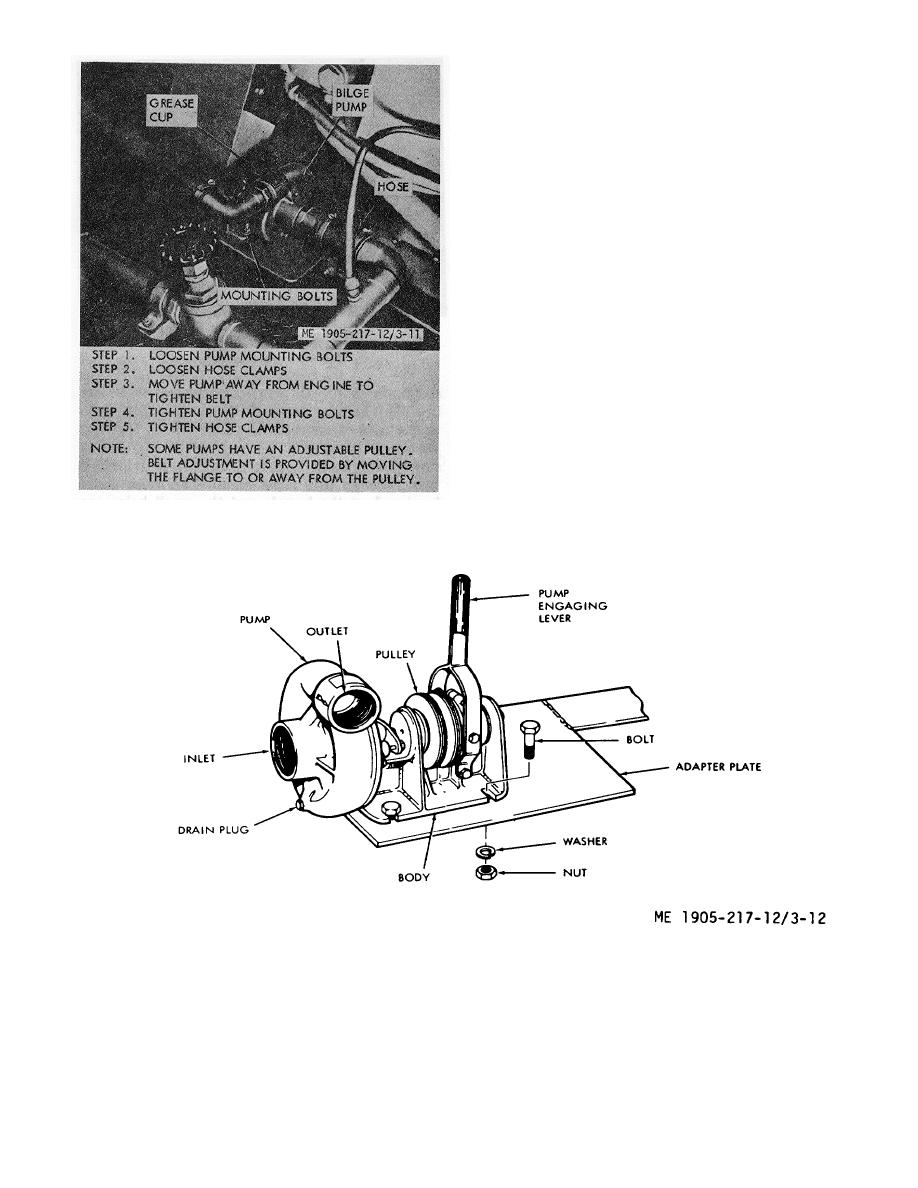

Figure 3-11. Adjusting bilge pump belt

been removed. With the bearings adjusted to obtain

these measurements, proper alignment of the shafting is

Figure 3-12. Bilge pump installation, hull numbers 8540 thru 8560 and 8580 thru 8018.

3-15

|

||

|

||