| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

(11) Attach the fuel rod to the injector control

tube lever with a pin and cotter pin.

(12) Place a new gasket on the governor control

housing and mount the governor cover on the housing

with the pin on the throttle shaft registering with the

machined slot in the differential lever.

(13) Install

the

four

cover

screws

with

(14) Connect throttle linkage.

(15) Attach the breather tube to the governor

housing.

(16) Adjust the governor and position the injector

rack control levers as instructed in paragraph 4-31.

4-31.

Governor

and

Injector

Rack

Control

Adjustments

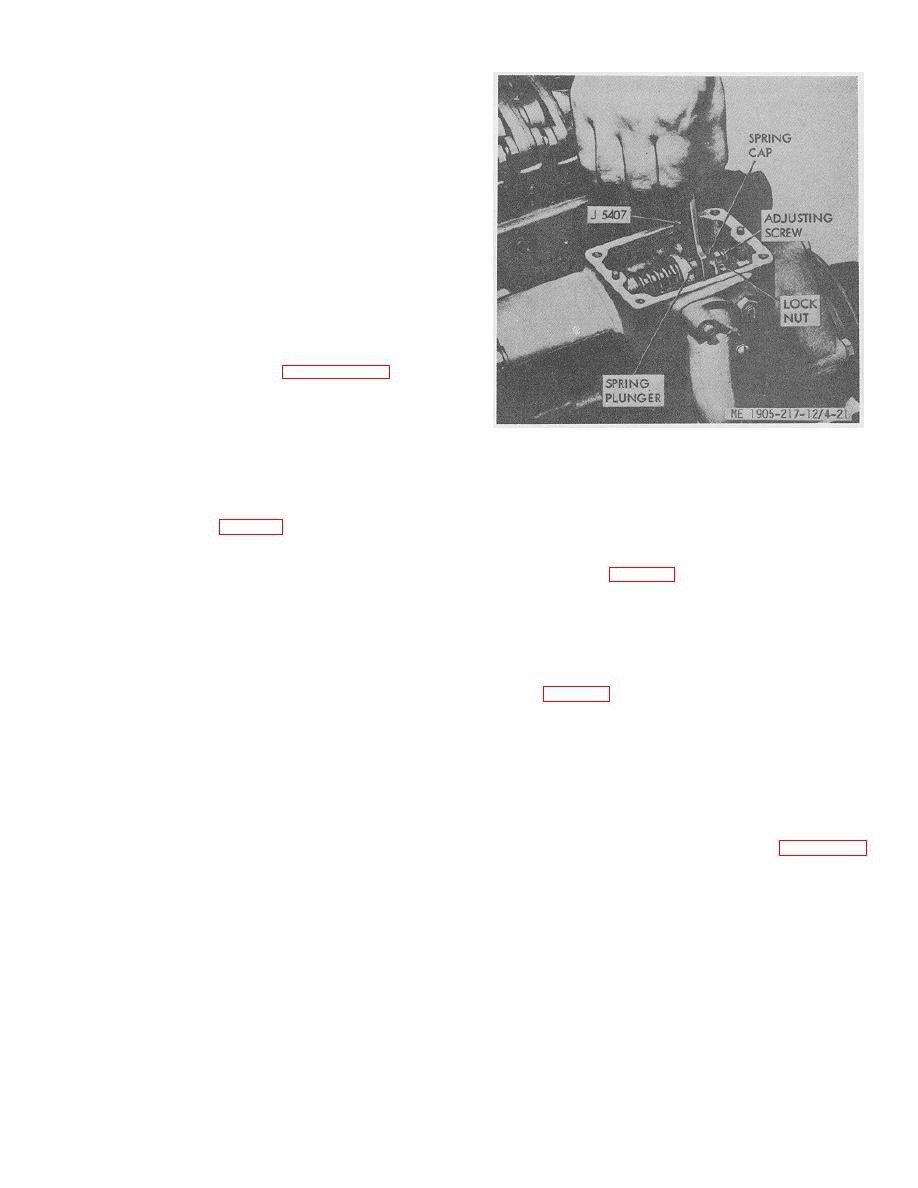

Figure 4-21. Adjusting Gap.

a. Governor Gap Adjustment. With the engine at

operating temperature, adjust the governor gap as

b. Positioning Injector Rack Control Levers.

follows:

(1) With the engine stopped, remove the two

The position of the injector racks must be correctly set in

attaching bolts and withdraw the governor high speed

relation to the governor. Their position determines the

spring retainer cover (13, fig. 4-20).

amount of fuel injected into each cylinder and ensures

(2) Back out the buffer screw (7) until it extends

equal distribution of the load. Adjust the No. 1 injector

approximately 5/8 inch from the locknut.

rack control lever (fig. 4-22) first to establish a guide for

(3) Start the engine and ,loosen the idle speed

adjusting the remaining injector rack control levers.

adjusting screw locknut and adjust the idle screw (1) to

obtain the desired idle speed.

(1) Disconnect any linkage attached to the

Hold the screw and tighten the locknut to retain the

governor speed control lever.

adjustment. The recommended idle speed is 550 rpm.

(4) Stop the engine and remove the governor

(2) Loosen the idle speed adjusting screw

cover and lever assembly.

locknut (fig. 4-20) and back out the idle speed adjusting

(5) Remove the valve rocker cover.

screw until 1/2 inch of the threads project from the

(6) Remove the fuel rod (17) from the

locknut %-hen the nut is against the high speed plunger.

differential lever and the injector control tube lever.

(7) Check the gap between the low speed

(3) Loosen all of the inner and outer injector

spring cap and the high speed spring plunger with gage

rack control lever adjusting screws. Be sure all of the

(0.170 in.) J5407 as shown in figure

control levers are free on the injector control tube.

(8) If required, loosen the locknut and turn the

gap adjusting screw until a slight drag is felt on the gage.

(4) Move the governor speed control lever to

(9) Hold the adjusting screw and tighten the

the maximum speed position as shown in figure 4-22.

locknut.

Hold the lever in that position with light finger pressure.

(10) Recheck the gap and readjust if necessary.

Turn the inner adjusting screw on the No. 1 injector rack

(11) Install the fuel rod between the governor

control lever down until a slight movement of the control

and injector control tube lever.

tube is observed or a step up in effort is noted. This will

(12) Install the governor cover and lever

place the No. 1 injector rack in the full-fuel position. Turn

assembly.

the outer adjusting screw down until it bottoms lightly on

the injector control tube. Then, alternately tighten both

the inner and outer adjusting screws.

4-26

|

||

|

||