| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

b. Inspection. The blower may be inspected for

4-36.

Air Silencer

any of the following conditions without being removed

from the engine. However, the air inlet silencer must be

a. General.

removed. Refer to higher echelon if inspection indicates

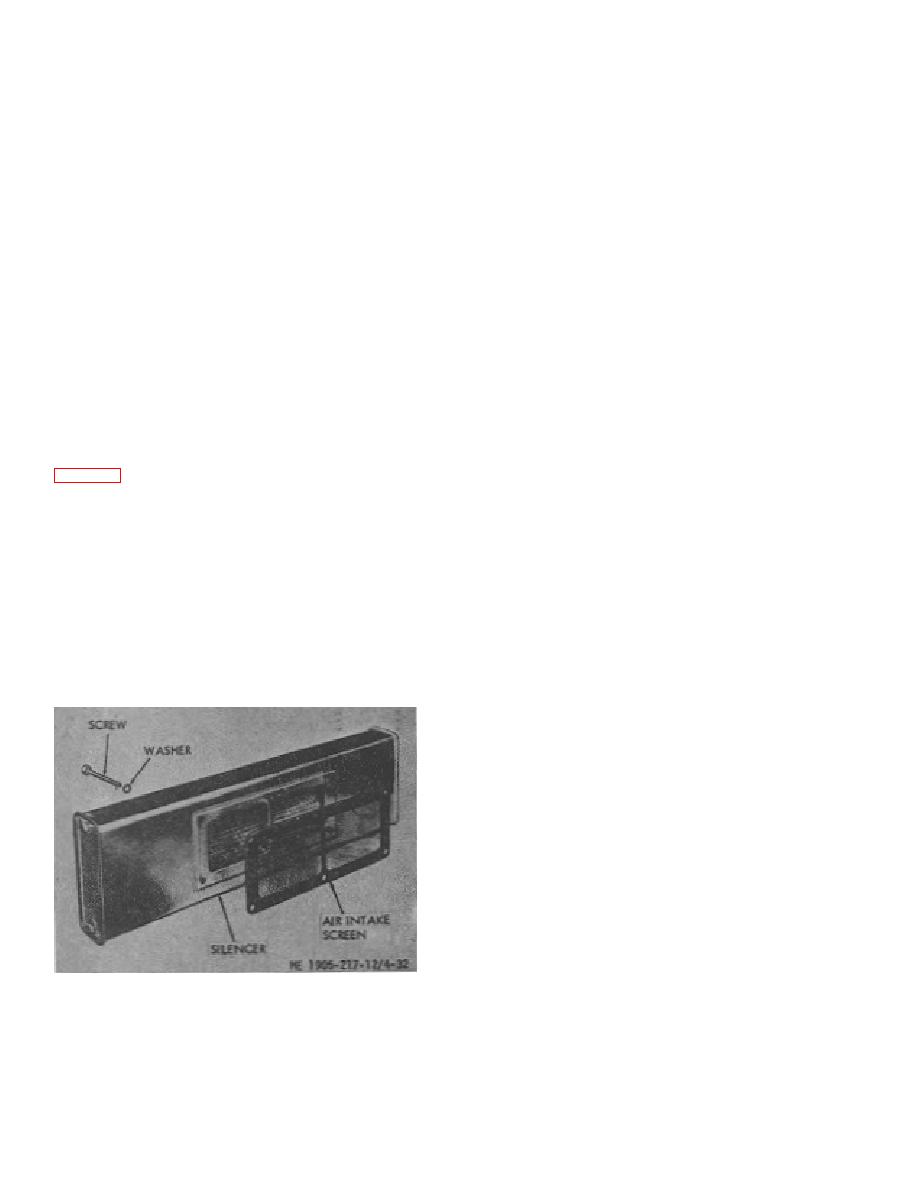

(1) The air silencer is attached to the air

that blower repair is required.

intake side of the blower rotor housing. A perforated

sheet metal partition divides the silencer into two

CAUTION

sections. The inner portion forms an air duct the entire

length of the silencer. Air enters this duct from both ends

When inspecting a blower on an engine with the engine

and flows toward the outlet opening at the center and

running, keep fingers and clothing away from the moving

then into the blower. The outer portion is filled with

parts of the blower and run the engine at low speeds

sound absorbent, flameproof, felted-cotton waste.

only.

(2) An air intake (blower) screen is used

between the air silencer and the blower housing to

(1) Dirt or chips drawn through the blower will

prevent foreign objects from entering the blower.

b. Removal.

make deep scratches in the rotors and housing and

throw up burrs around such abrasions. If burrs cause

(1) Remove the bolt that retains the breather

interference between the rotors or between the rotors

pipe to the air silencer.

and the housing, the blower should be removed from the

(2) While supporting the silencer, remove the

engine and the parts dressed down to eliminate the

six attaching bolts and washers. Then remove the

interference, or the rotors must be replaced if they are

silencer and air intake screen from the blower.

too badly scored.

c. Cleaning. Clean or replace the air intake screen

(2) Leaky oil seals are usually manifested by

the presence of oil on the blower end plates and rotors or

the inside surfaces of the housing. This condition may

d. Installation. Install the screen and silencer in

be checked by running the engine at low speed and

reverse order of removal.

directing a light into the rotor compartment at the end

plates and the oil seals. A thin film of oil radiating away

4-37.

Blower

from the seals is indicative of an oil leak.

a. General. The blower supplies the fresh air

CAUTION

needed for combustion and scavenging. Its operation is

similar to that of a gear-type oil pump. Two hollow three-

Stop engine prior to grasping the top rotor and attempt to

lobe rotors revolve with very close clearances in a

rotate it.

housing bolted to the cylinder block. To provide

continuous and uniform displacement of air, the rotor

(3) A worn blower drive, resulting in a rattling

lobes are made with a helical (spiral) form.

noise inside the blower, may be detected by grasping the

top rotor firmly and attempting to rotate it. Rotors may

move from 3/8 inch to 5/8 inch, measured at the lobe

crown, with a springing action. When released, the

rotors should move back at least 1/4 inch. If the rotors

cannot be moved as directed above, or if the rotors move

too freely, the flexible blower drive coupling should be

inspected and replaced if necessary.

(4) Loose rotor shafts or damaged bearings

will cause rubbing and scoring between the crowns of the

rotor lobes and the mating rotor roots, between the rotors

and the end plates, or between the rotors and the

housing. Generally, a combination of these conditions

exists. A loose shaft usually causes rubbing between the

rotors and the end plates. Worn or damaged bearings

will cause rubbing between the mating rotor

Figure 4-32. Blower air inlet silencer assembly.

4-35

|

||

|

||