| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

(3) The oil cooler element should be

removed and cleaned periodically, or at the time of

each engine or marine gear overhaul, to prevent

overheating of the marine gear oil.

b. Removing Oil Cooler Element (fig. 4-59).

(1) Drain the cooling system.

(2) Remove engine oil filter and bracket.

(3) Remove oil tubes from engine oil cooler

cover.

(4) Matchmark the end of the oil cooler

cover, cooler element, and cooler housing with a

punch or file so they can be installed in their same

relative positions.

(5) Remove the bolts and lockwashers

securing the oil cooler cover to the oil cooler housing.

Then, pull the cover away from the element.

NOTE

If necessary, loosen the oil tube clips at the

side of the cylinder block.

(6) Remove the oil cooler element from the

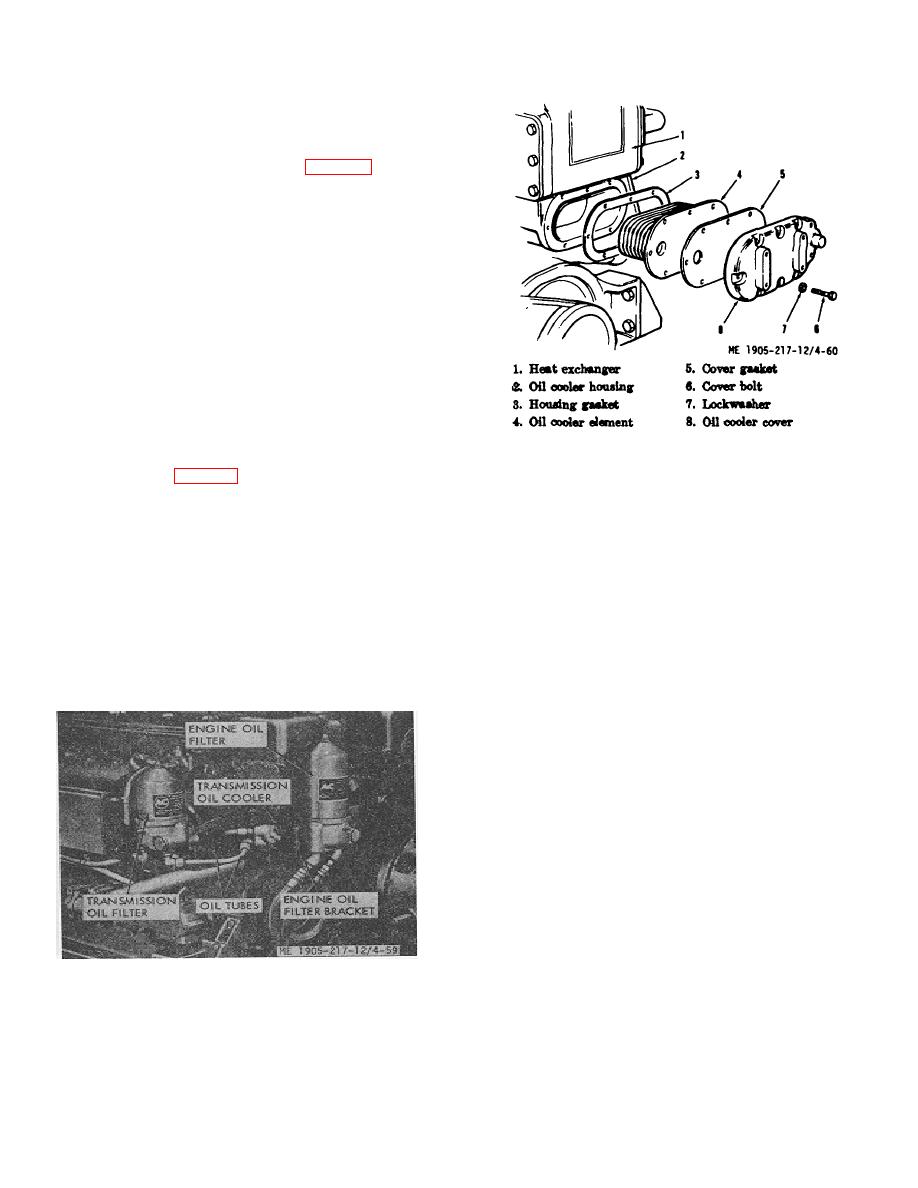

Figure 4-60. Transmission oil cooler details.

oil cooler housing (fig. 4-60).

(7) Remove the gaskets from the oil cooler

(2) Clean the element before sludge hardens. If

over, element, land housing.

the oil passages -are badly clogged, circulate an Oakite or

c. Cleaning Oil Cooler Element.

alkaline solution through the core and flush thoroughly with

(1) Clean oil side of element. Circulate a

clean, hot water.

solution of trichloroethylene through the core passages

with a force pump to remove the carbon and sludge.

(3) Clean water side of element. After cleaning

the oil side of the element, immerse it in the following

CAUTION

solution: Add one-half (1/2) pound of oxalic acid to each two

This operation should be done in the open

and one-half (2 1/2) gallons of solution composed of one-

or in a well ventilated room when

third (1/3) muriatic acid and two-thirds (2/3) water. The

trichloroethylene or other toxic chemicals

cleaning action is evidenced by bubbling and foaming. The

process must be care fully watched and, when bubbling

are used for cleansing.

stops (this usually takes from 30 to 60 seconds), the

element should be removed from the cleaning solution and

thoroughly flushed with clean, hot water. After cleaning, dip

the element in light oil.

NOTE

Cleaning an oil cooler element is not recommen ded

where the history of usage shows a marine gear

failure which has released metal particles from

worn and broken parts, into the lubricating oil. In this

instance, the replacement of the oil cooler is strongly

recommended.

d. Installing Oil Cooler Element.

(1') Affix a new gasket to the oil cooler housing (fig.

4460).

Figure 4-59. Transmission oil cooler removal.

(2) Affix a new gasket to the inner face of the oil

cooler cover.

(3) Install the oil cooler element into the oil cooler

housing with the matchmarks previously placed on the

element and housing in alignment.

4-64

|

||

|

||