| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-12

4-81. Steering System Valve Adjustments (HuIH1

Numbers 8520 thru 8560 and 8580 thru 8618)

See figure 1-9 or 1-10 for valve locations in system.

a. Relief Valve. This valve is to be set for a

maximum system pressure of 1050 psi. Refer to

b. Flow Divider. This valve is a preset priority type

supplying a constant 2 gpm to the helm unit. Excess oil is

bled back to the reservoir.

c. Counterbalance Valves (2). The counterbalance

valves induce an artificial pressure on the low pressure

side of the steering cylinders to prevent the rudder from

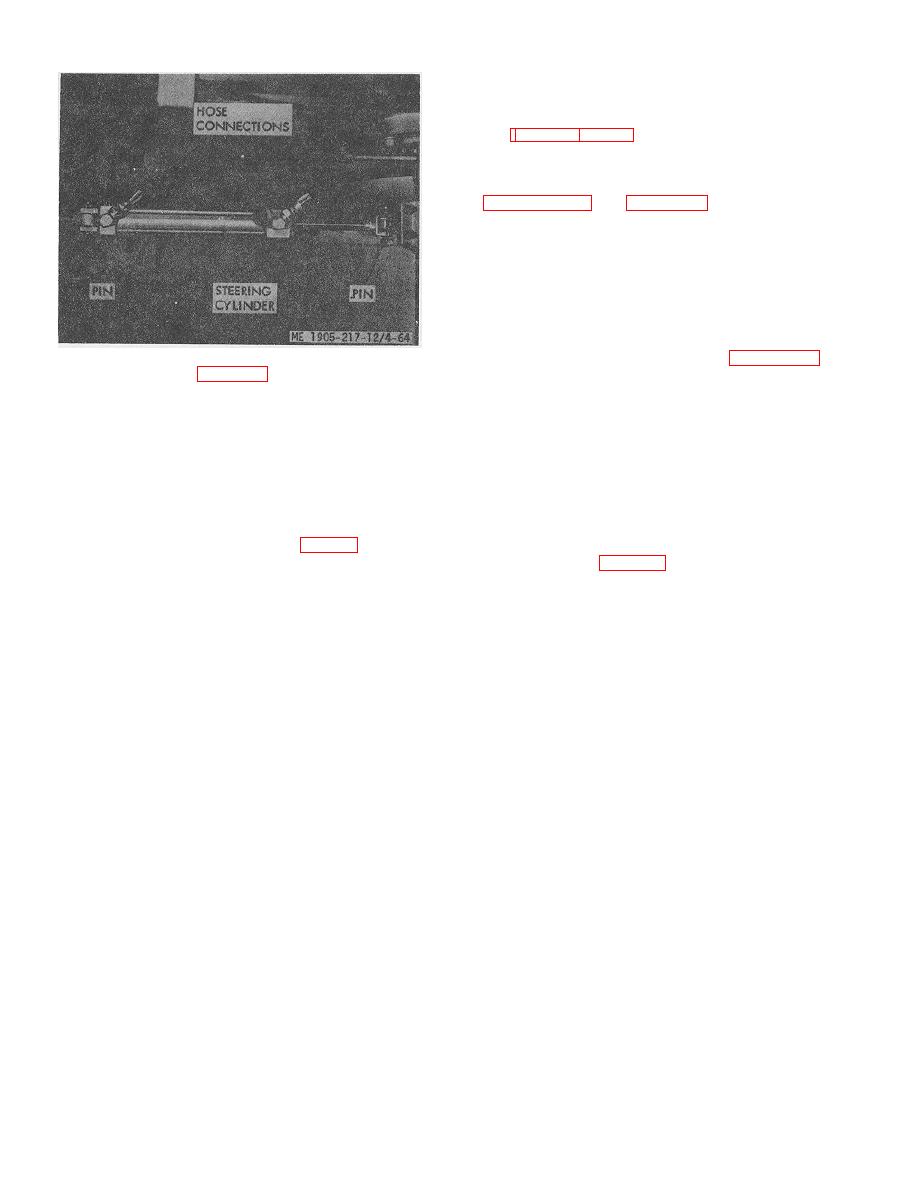

Figure 4-64. Steering cylinder removal

running ahead of the pumps. See figure 4-70. These

b. Relief Valve (fig. 4-67). Adjust by putting the

valves are set at 1,000 psi.

helm hardover in either direction with engines running (1

pump only supplying system). Remove cap from the

4-82. Helm Unit and 'Steering Wheel

relief valve, loosen nut, and back off screw until it no

a. General. The helm unit and other valves control

longer bears on the spring. Hold the helm in a hardover

the direction and volume of flow of the hydraulic oil in the

position and slowly turn down screw until the pressure

steering system. The helm unit directs the oil to one side

gage reads 1,500 psi indicating that the valve is relieving

or the other of the cylinders and limits the flow according

at 1,500 psi. Lock this setting with nut and replace cap.

to the speed at which the steering wheel is turned. In

c. Flow Control Valve. This valve is preset at the

event of pump failure the helm unit will also act as a

factory and cannot be adjusted.

pump when turned manually.

d. Double Over-Center Valve (fig. 4-68). Adjust

with the screws. Loosen nuts and back off screws until

b. Removal (fig. 4-71).

they no longer bear on springs. Rotate the helm and

(1) Remove steering wheel.

slowly turn down screws until the pressure gage reads

(2) Remove access covers in pilot house panel.

150 psi indicating that a pressure of 150 psi is required to

(3) Clean the four tube connections at helm unit

open the over-center valve and start motion in the

with a solvent-wetted cloth so that contamination will not

cy1.inders. This operation must be performed 'first in one

enter the system.

direction, adjusting one side of the over-center valve,

(4) Disconnect the four tubes or hoses as

then repeated for the other side. With the above setting

applicable from the helm unit

the over-center valve will resist a kick-back force from

(5) Remove four mounting bolts and remove

the rudders equal to the force exerted by the cylinders at

helm unit.

1,500 psi. This adjustment must be made with the

c. Installation. Install helm unit in reverse order of

cylinders at mid-stroke and the craft motionless in the

removal.

water so that no load is applied to the cylinders.

4-69

|

||

|

||