| Tweet |

Custom Search

|

|

|

|

||

|

||

TM 55-1905-217-12

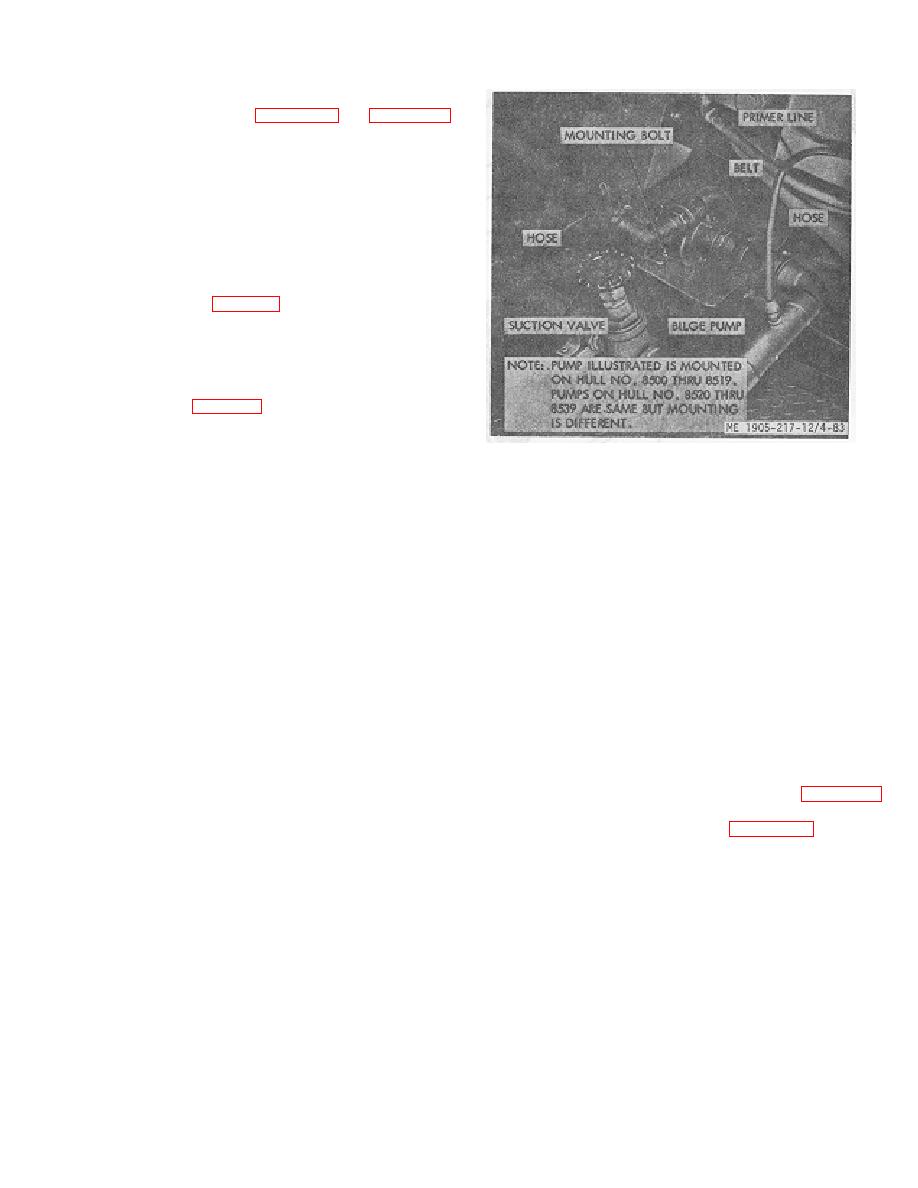

pump is belt-driven from the inboard engine of the

starboard propulsion unit. See figure 4-83. See figure 3-12

for bilge pump installation on hull numbers 8540 thru

8560 and 8580 thru 8618. These pumps have a single

moving part, the impeller and shaft assembly. Only one

grease cup requires attention. See lubrication order.

The grease cup provides lubrication for the bronze

bushing on impeller end of shaft. Ball bearing at other

end of shaft is grease-pack and requires no attention.

b. Packing Gland Adjustment. Do not tighten more

than necessary to stop leakage of water. Repack when

necessary with 1/8-inch metallic string packing.

c. Pump Removal (fig. 4-83).

(1) Close primer line valve and suction valve.

(2) Loosen hose clamps and slide hoses away

from pump.

(3) Loosen mounting bolt nuts and remove belt.

(4) Remove mounting bolts and remove pump.

d. Disassembly (fig. 4-84).

(1) Remove the pump housing from the clutch

body by removing the six attaching nuts and, washers.

Remove carefully to protect gasket.

Figure 4-83. Bilge pump removal

(2) Remove end nut and clamp washer from

the clutch end of unit and press or drive out the shaft and

f.

Reassembly.

impeller assembly from ball bearing and while supporting

(1) Reassemble in reverse order of

the clutch body. When the shaft is being removed, look

disassembly.

for spacing shim before pulling the shaft through the

(2) After 'pump has been assembled and nuts

packing and gland as shim will be damaged if left on the

tightened, check clearance between face of impeller and

shaft.

housing. The clearance shall be 0.010-to 0.012iinch and

(3) To remove ball bearing, first remove the

is controlled by the number of gaskets between housing

packing and gland. Remove the bearing snap retaining

and body. Check the clearance between the back face

rings and insert a brass drift through the -housing end to

of the impeller and the clutch body. The clearance shall

the inner race of the bearing. Tap the drift lightly and

be 0.010-to 0.015-inch and -is controlled by shim

remove the bearing. The impeller should not be

thickness at shaft shoulder.

removed from the shaft.

(3) Shaft bearings are packed and do not

e. Inspection and Repair.

require lubrication.

(1) Inspect impeller housing and pressure plate

g. Installation. Install pump in reverse order of

for excessive wear.

removal.

(2) Inspect shaft for wear, scores, or burrs.

Inspect impeller for wear or damage.

4-102. Strainers and Lines

(3) Inspect packing glands for serviceability.

Locations of lines and strainers are indicated in, figure 2-14.

(4) Remove burrs by careful stoning or lapping.

No service is required except inspection of strainers

Round out nicks and uneven edges on impeller. Fit new

to be sure they are free from debris. Figure 4-85 depicts

parts to replace defective items. If impeller is damaged,

a typical foot valve installation used on hull -numbers

a new shaft assembly is required.

8540 thru 8560 and 8580 thru 8618.

4-103. Fuel Oil Heat Exchangers Hull 8540 Thru

8618)

a. General. The fuel oil heat exchangers are

vertically mounted in the raw water cooling lines -for

each engine muffler. The exchangers cool the surplus

fuel returning from the outlet side of the injector back to

the fuel tank.

4-82

|

||

|

||