| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

(a) When refacing a cylinder head, stamp the amount of stock removed on the face of the fire deck. Do not remove over

.020 inch of metal from the fire deck of any cylinder head. The distance from the top deck to the bottom (fire deck) of the

cylinder head must not be less than 3.536 inch (fig. 3-48).

Figure 3-48 . Minimum distance between top and bottom

faces of cylinder head.

(b) When a cylinder head has been refaced, check and correct the critical dimensions such as the protrusion of the valve

inserts, valves, in- jector tubes, and injector spray tips from the fire deck. Adjust the push rod length also in order to

prevent the valves from striking the top of the piston when the head is reinstalled on the engine.

(3) Check the cylinder head for leaks and cracks as follows:

(a) Seal off the water holes in the head by using steel plates and suitable rubber gaskets clamped in place by bolts.

(b) Install scrap or dummy injectors to insure seating of the injector tubes. Dummy injectors may be made up with old

injector nuts and bodies-the injector spray tip is not necessary. Tighten the injector clamp nuts or bolts to 20-25 lb-ft

(c) Drill and tap into one of the water hole cover plates for an air hose connection and apply 80-100 psi air pressure to the

water jacket. Then, immerse the head in a tank of water previously heated to 180 -200 0 F. for about fifteen to twenty

minutes to thoroughly heat the cylinder head. Leaks will be detected by noting any air bubbles which may appear in the

water. Check for leaks at the bottom and top of the injector tubes, oil gallery, cylinder head stud holes, exhaust ports, and

the top, bottom and sides of the head itself.

(d) Relieve the air pressure, remove the cylinder head from the water tank, remove the water hole plates and gaskets, and

dry the cylinder head with compressed air. Replace any leaking injector tubes. If inspection revealed any cracks, replace

the cylinder head.

(4) Install new injector tubes if the old tubes leaked or the cylinder head was refaced.

(5) Check the valve seat inserts for cracks or burning. Also, check the valve guides for scoring.

(6) Inspect the cam follower bores in the cylinder head for scoring or wear. Light score marks may be cleaned up with

crocus cloth wet with fuel oil. The inside diameter of the bores are 1.062 inches to 1.063 inches in a new cylinder head

(1.065 inches maximum on a used head). If the bores are excessively scored or worn so that the cam follower-to-head

clearance exceeds .006 inches, reject the cylinder head.

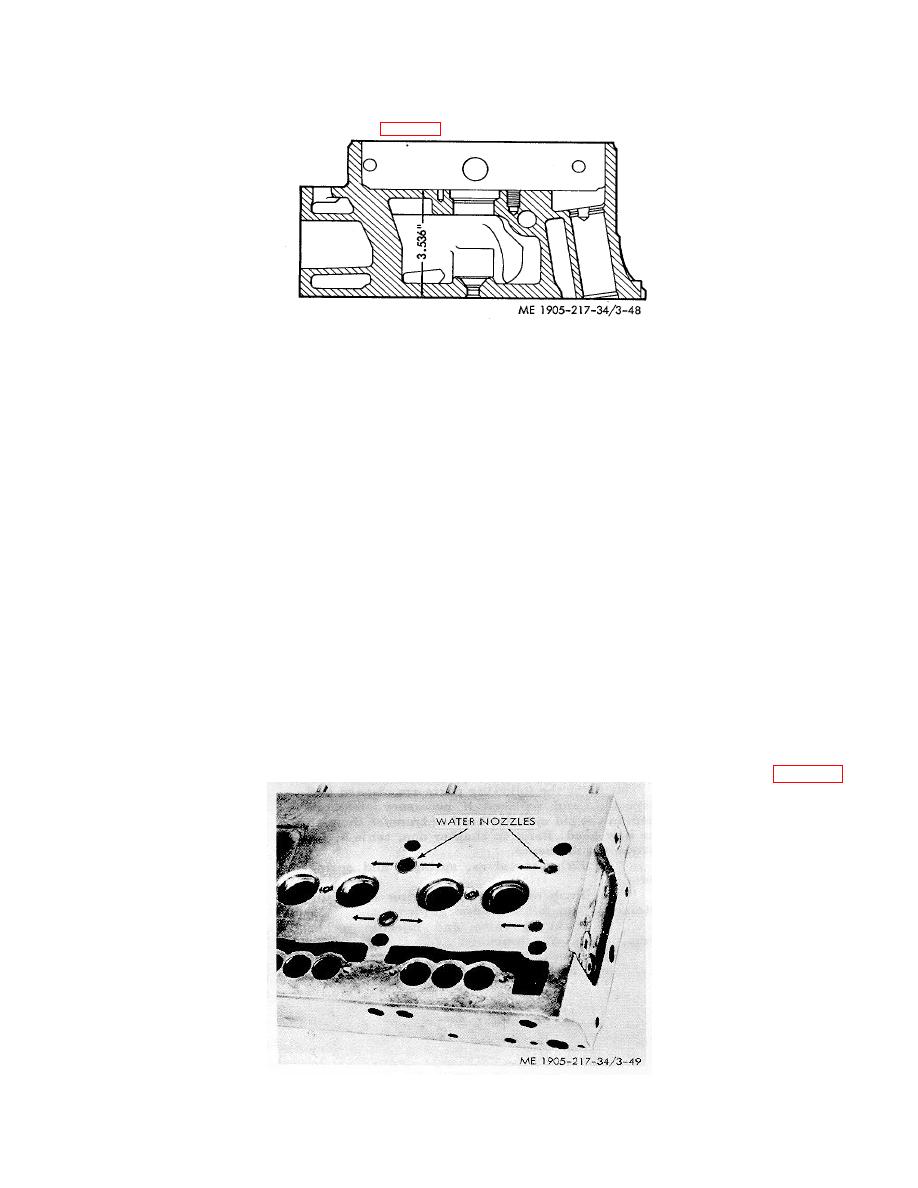

(7) Check the cylinder head water nozzles for looseness. Install or replace the cylinder head water nozzles as follows:

(a) Be sure that the water inlet ports in the bottom of the head are clean and free of scale. The water holes at each end of

the head may be cleaned up with /2 inch drill and all of the other water holes may be cleaned up with a 13/16 inch drill.

Break the edges of the holes slightly.

(b) Press the nozzles in place with the nozzle openings parallel to the longitudinal center line of the cylinder head. Install

the /2 inch diameter nozzles at the ends of the cylinder head with their openings toward the center of the engine (fig. 3-49).

Figure 3-49, Correct installation of water nozzles in cylinder head

3-67

|

||

|

||