| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

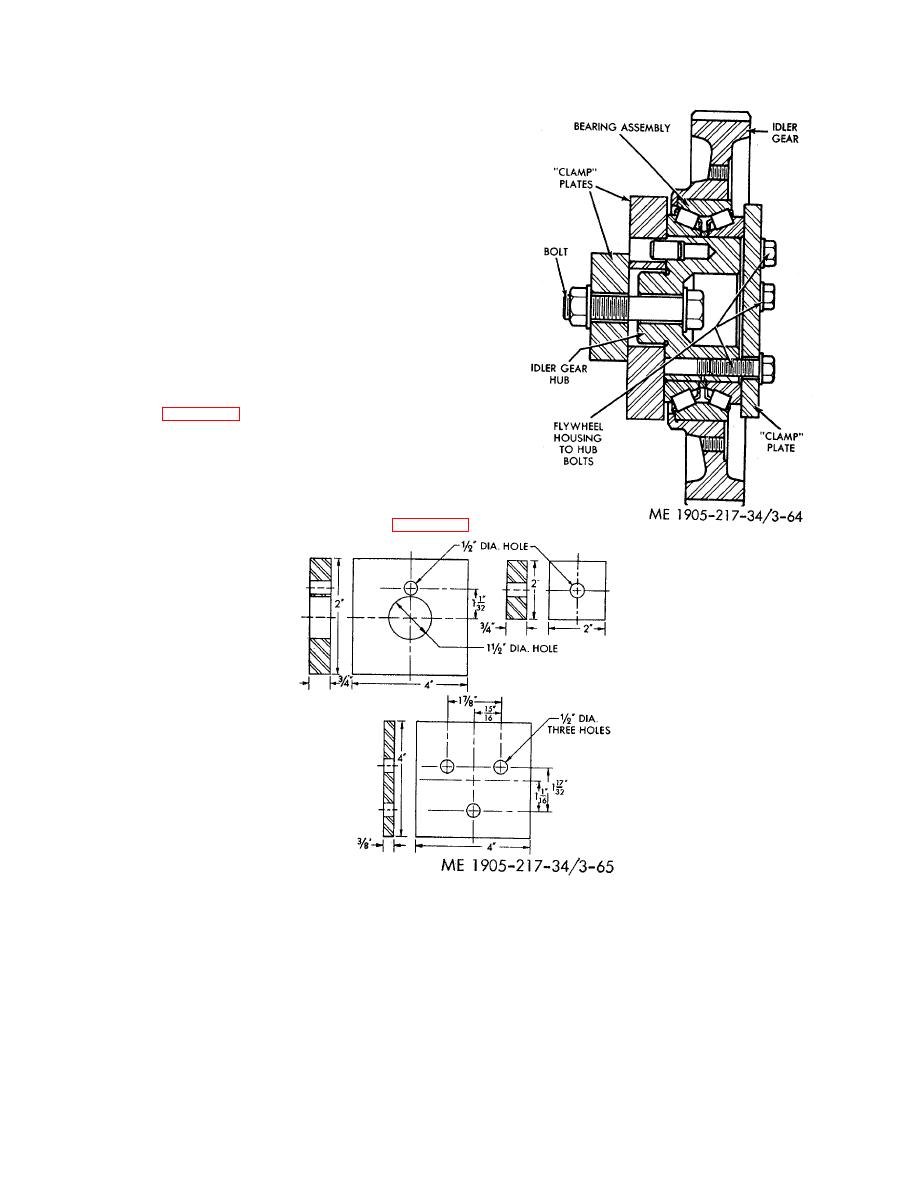

This method of pre-loading is measured, in terms of "pounds-pull", by

the effort required at the outer diameter of the gear to turn the bearing

cup in relation to the bearing cones.

(2) Any time an idler gear assembly has been removed from

an engine for servicing or inspection, while performing engine

overhaul or other repairs, the pre-load should be measured as part of

the operation.

(3) After the idler gear, hub, and bearing are assembled

together, the bearing should be checked to ascertain that the gear

may be rotated on its bearing without exceeding the maximum torque

specifications, nor be so loose as to permit the gear to be moved in

relation to the hub by tilting, wobbling or shaking the gear.

(4) If the mating crankshaft and camshaft or balance shaft

gears (depending upon engine rotation) are not already mounted on

the engine, the torque required to rotate the idler gear may be

checked by mounting the idler gear in position on the engine, using a

steel plate 4" square and 3/8" thick against the hub and cone as

outlined below.

(5) However, if the crankshaft and camshaft gears are on the

engine, a suitable fixture, which may be held in a vise, may be made

as shown in figure 3-64. Three plates, a 1/2"-13 x 2 3/4" bolt and a

plain washer are used with a 1/2 "-13 nut and plain washer for

mounting. One of the plates is used to take the place of the flywheel

housing, and the other two plates, the cylinder block. "Engine-

mounted" conditions are simulated by tightening the nut to 80-90 lb-ft

Figure 3-64. Fixture for testing bearing pre-load

torque and tightening the three plate-to-hub attaching bolts to 25-40

lb-ft torque. The components of the fixture may be made from steel

stock in accordance with the dimensions shown in figure 3- 65.

Figure 3-65. Plates for bearing test fixture.

3-86

|

||

|

||