| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

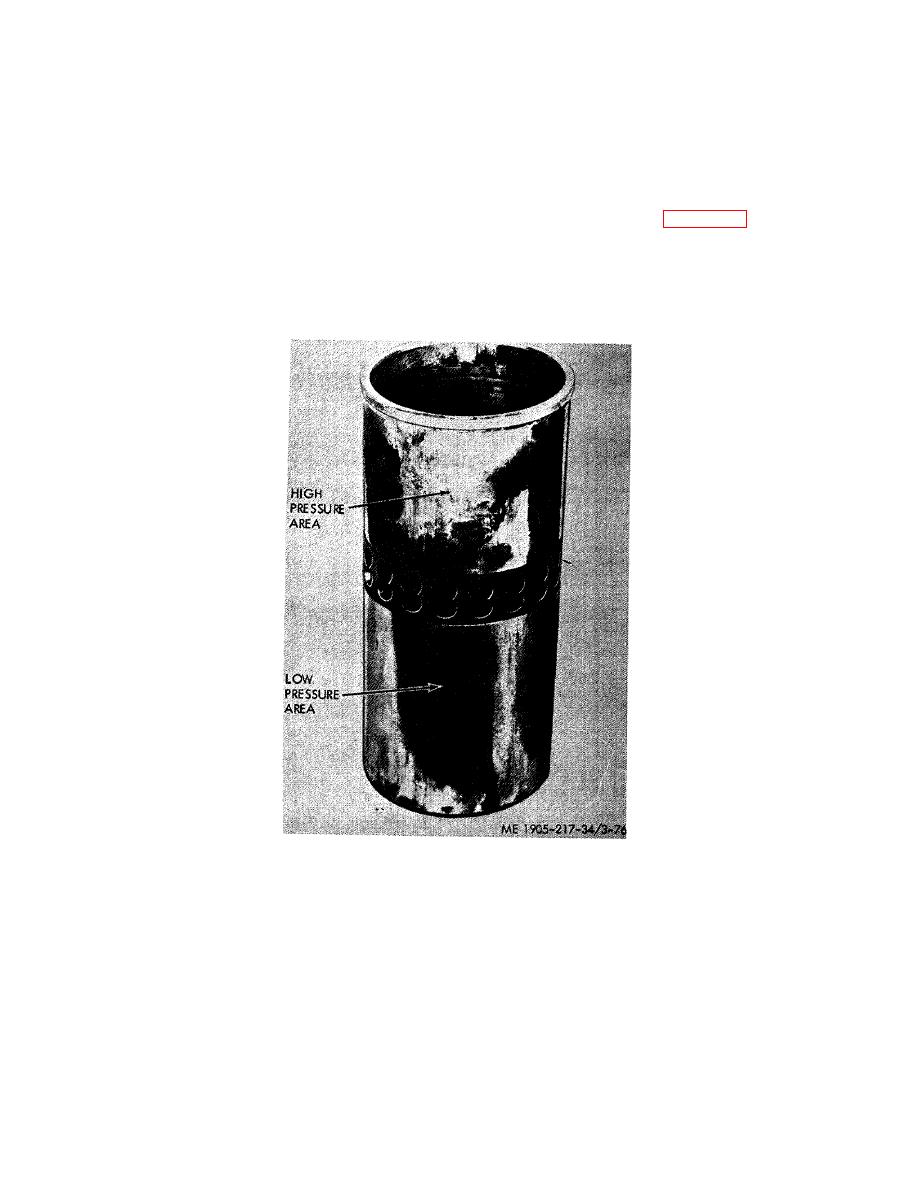

from the liner to the block and to the engine coolant. Poor contact between the liner and the block bore may be

indicated by stains or low pressure areas on the outer surface of the liner

(4) Examine the outside diameter of the liner for fretting. Fretting is the result of a slight movement of

the liner in the block bore during engine operation, which material from the block to adhere to the liner. These

metal particles may be removed from the surface of the liner with a coarse, flat stone.

(5) The liner flange must be smooth and flat on both the top and bottom surfaces. Check for cracks at

the flange. The liner insert must also be smooth and flat on the top and bottom surfaces. Replace the insert if

there is evidence of brinelling (cracking of surface).

(6) Measure the inside diameter of the liner at the various points indicated in figure 3-77. Use cylinder

bore gage J 5347, which has a dial indicator calibrated in .0001 inch increments, as it is rather difficult to obtain

accurate measurements with a micrometer. Set the cylinder bore gage to zero in master ring gage J 5580-1.

Also, check the liner for taper and out-of- round. Measurements must be made with the liner installed in the

proper bore of the cylinder block.

Figure 3-76. High and low pressure contact areas on cylinder liner

3-105

|

||

|

||