| Tweet |

Custom Search

|

|

|

||

TM 55-1905-217-34

CHAPTER 5

REPAIR OF PROPELLER, SHAFT, RAMP, AND HATCHES

Section I. PROPELLER AND SHAFT ASSEMBLY

5-1. Propeller

a. Removal. Remove the propeller (TM 55-1905-217-12).

b. Inspection. Inspect for damaged or bent blades.

c. Repair. The tools necessary for small craft propeller repair are a blacksmith's forge, an anvil, files,

and an oxacetylene torch. Straightening and finish work can be conveniently and economically executed in the

field.

(1) Importance of Propeller Straightening. Straightening and balancing minimizes outboard bearing

maintenance and avoids over-loading engines, loss of efficiency and speed, and poor performance of

misshaped propeller.

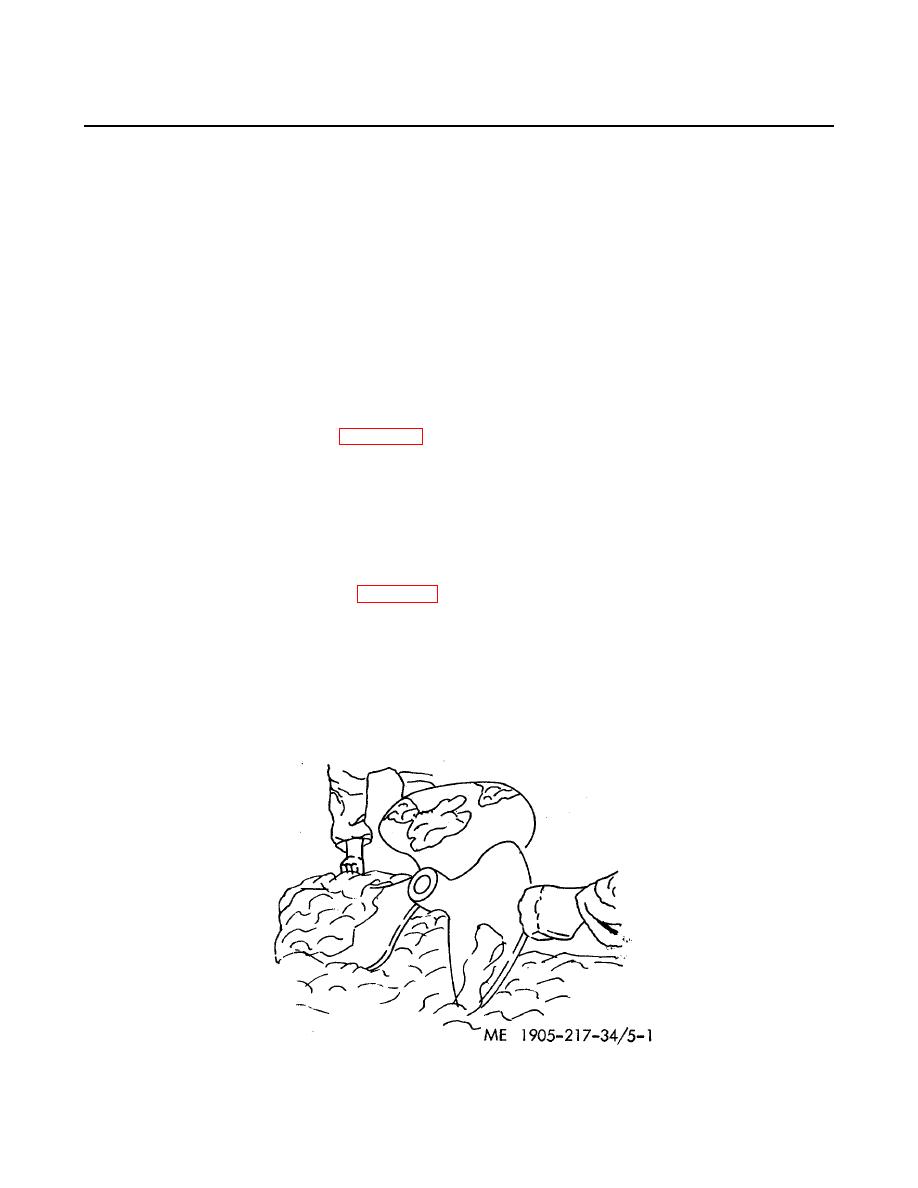

(2) Heating Propellers. Small bends or depressions in bronze propellers can be straightened while

the propeller is cold. Because cold working hardens bronze, larged bends or irregularities must be repaired

using heat to prevent cold cracks from occurring. When heat is used, heat propeller to a dull red color in a

forge or with a gas flame. For overall heating where large surfaces are involved, the forge is faster and gives a

more uniform application of heat. Figure 5-1 shows a propeller being heated with a forge. For small or

localized repairs, a gas flame should be used.

CAUTION

Bronze becomes weak at high temperatures and the propeller, if struck, can

sag or break. Exercise care when handling or repairing a heated propeller.

(3) Straightening the Blade. On small propellers, tightly rolled bends are unrolled with blacksmith's

tongs. Other irregularities are peened. It is advantageous to peen a bend on its concave or hollow side. On

small propellers, strike the blade with a light hammer while backing the peening with the blade on an anvil. A

typical peening operation is shown in figure 5-2. Large propellers are peened by using air hammers with a

round edge calking tool. The metal unrolls like wet leather under the hammer when the blade is at the correct

temperature. Work should be stopped and the propeller reheated when the sound of the metal under the

hammer changes from a dull, flat sound to a sharper, ringing sound. Several propellers can be heated and

straightened at the same time. Most blades can be reshaped with two or three heatings. This can be done

alternately so that the blade of one propeller is cooling while another is being heated and worked. In this way,

the annealing is continuous, and no water cooling is necessary because a separate annealing step is not used.

During straightening operations, the propeller should be compared occasionally to a propeller pitch block.

Figure 5-1. Heating propeller with a forge.

5-1

|

||

|

||