| Tweet |

Custom Search

|

|

|

||

TM 55-1905-219-14-10

5-19.1. CAMSHAFT ASSEMBLY AND GEAR TRAIN - MAINTENANCE INSTRUCTIONS.

(Continued).

LOCATION

ITEM

ACTION

REMARKS

INSPECTION (Cont)

f.

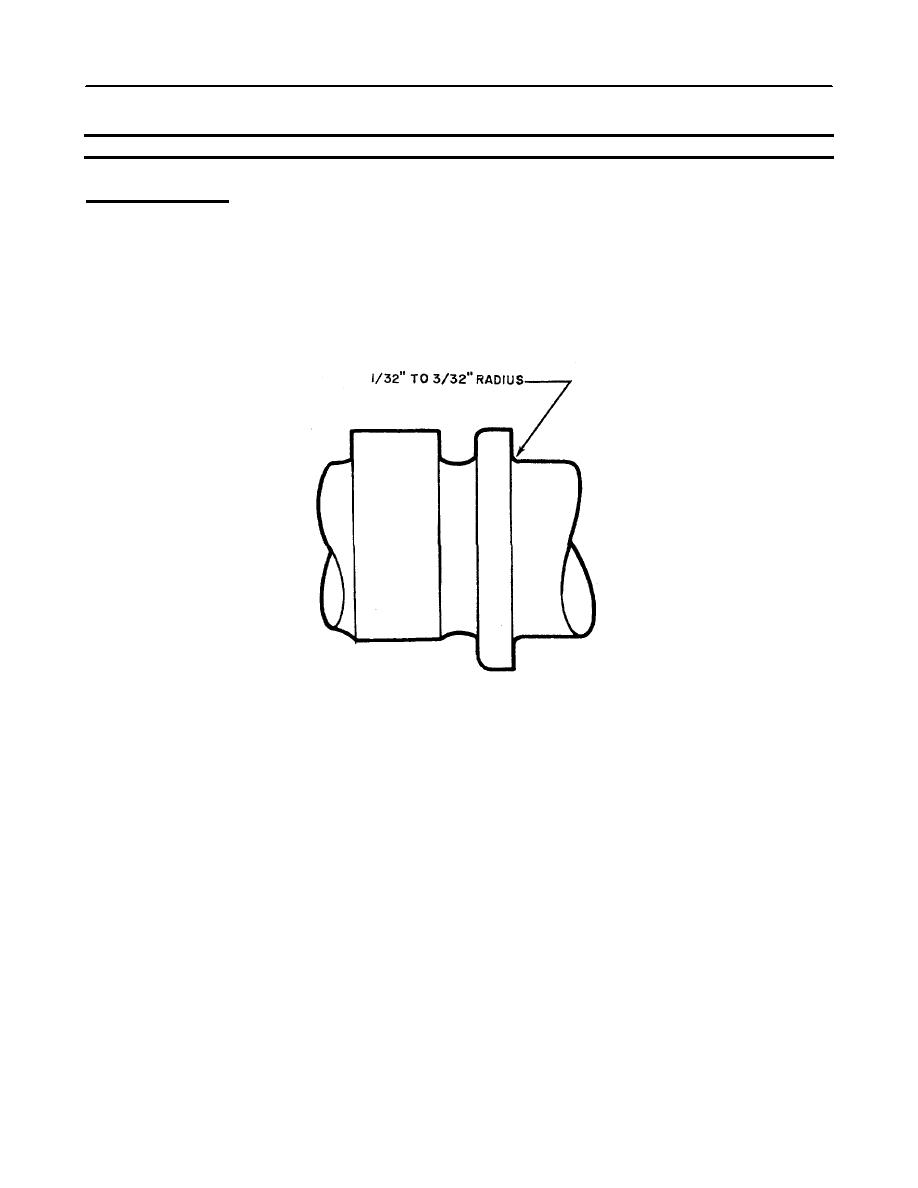

When the thrust surfaces of a camshaft are

ground undersize, a radius of 1/32" to

3/32" must be maintained between the bear-

ing surface of the thrust collar shoulder

and the bearing surface of the camshaft.

A fillet radius gage may be used to measure

the specified radii.

g. Inspect the bushings in the front and rear

camshaft end bearings. Replace the bushings

if they are worn excessively or have turned

in the bearing. New bushings must be finish

bored to a 20 R.M.S. finish after installa-

tion and checked for the proper press fit,

which is indicated if the bushings will not

move when a 2000 pound end load is applied.

Also, the inside diameter of the bushings

must be square with the rear face of the

bearing within .0015" total indicator read-

ing and concentric with the outside diameter

of the bearing housing within .002" total

indicator reading. The bushings must pro-

ject .045" to .055" from each end of the

rear camshaft end bearings. The bushings

in the front camshaft end bearings must be

flush with the ends of the bushing bore.

5-332

|

||

|

||