| Tweet |

Custom Search

|

|

|

||

TM 55-1905-219-14-10

5-43. CYLINDER BLOCK-MAINTENANCE INSTRUCTIONS (Continued).

LOCATION

ITEM

ACTION

REMARKS

INSPECT (Cont.)

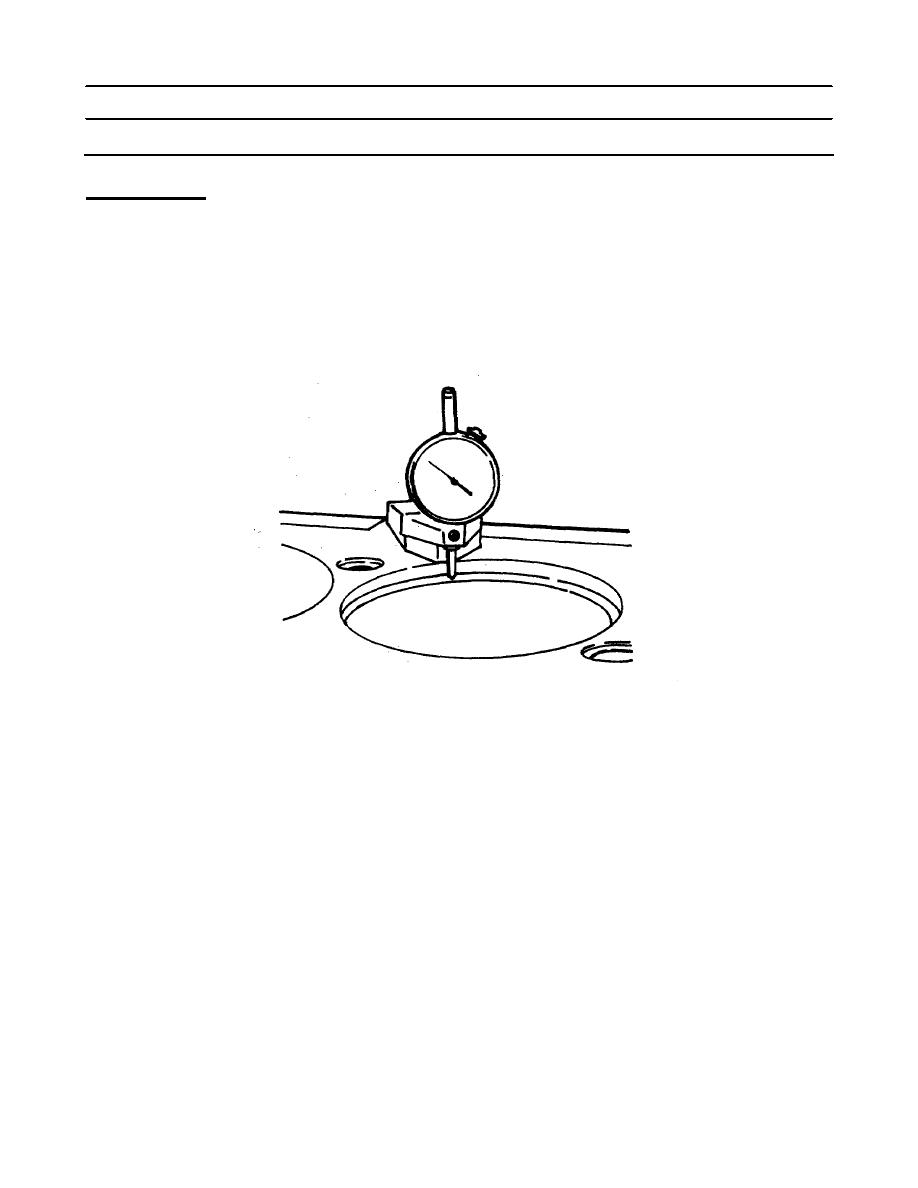

h. Make sure the cylinder liner counterbores in the block are clean and free of dirt.

Then check the depth. The depth must be .4770 inch to .4795 inch and must not

vary more than .0015 inch throughout the entire circumference. Thecounterbored

surfaces must be smooth and square with the cylinder bore within .001 inch total

indicator reading. There must not be over .001 inch difference between any two

adjacent cylinder counterbores when measured along the cylinder longitudinal

center- line of the cylinder block.

i.

Check the main bearing bores as follows:

(1) Check the bore diameters with the main bearing caps in their original positions.

Lubricate the bolt threads and bolt head contact areas with a small quantity of

International Compound No. 2, or equivalent. Then install and tighten the bolts to

165-175 lb-ft (223.7-237.3 Nm) torque. When making this check, do not install the

main bearing cap stabilizers. The specified bore diameter is 4.812 inch to 4.813

inch. If the bores do not fall within these limits, the cylinder block must be rejected.

5-630

|

||

|

||