| Tweet |

Custom Search

|

|

|

||

TM 55-1905-219-14-4

3-19.

EXPANSION TANK - MAINTENANCE INSTRUCTIONS

a. In the expansion tank and keel cooling systems, the coolant is drawn by the raw water pump from the

expansion tank and keel cooler, and is forced through the engine oil cooler, cylinder block, cylinder heads,

exhaust manifolds and finally to the thermostat housings. A by-pass from the thermostat housings to the inlet

side of the water pump permits circulation of coolant through the engine while the thermostats are closed.

b. In the keel cooling system, coolant flows through the keel cooling coils and then to the suction side of

the raw water pump for recirculation. The heat of the engine coolant is passed through the keel cooler coils

and out to the sea water.

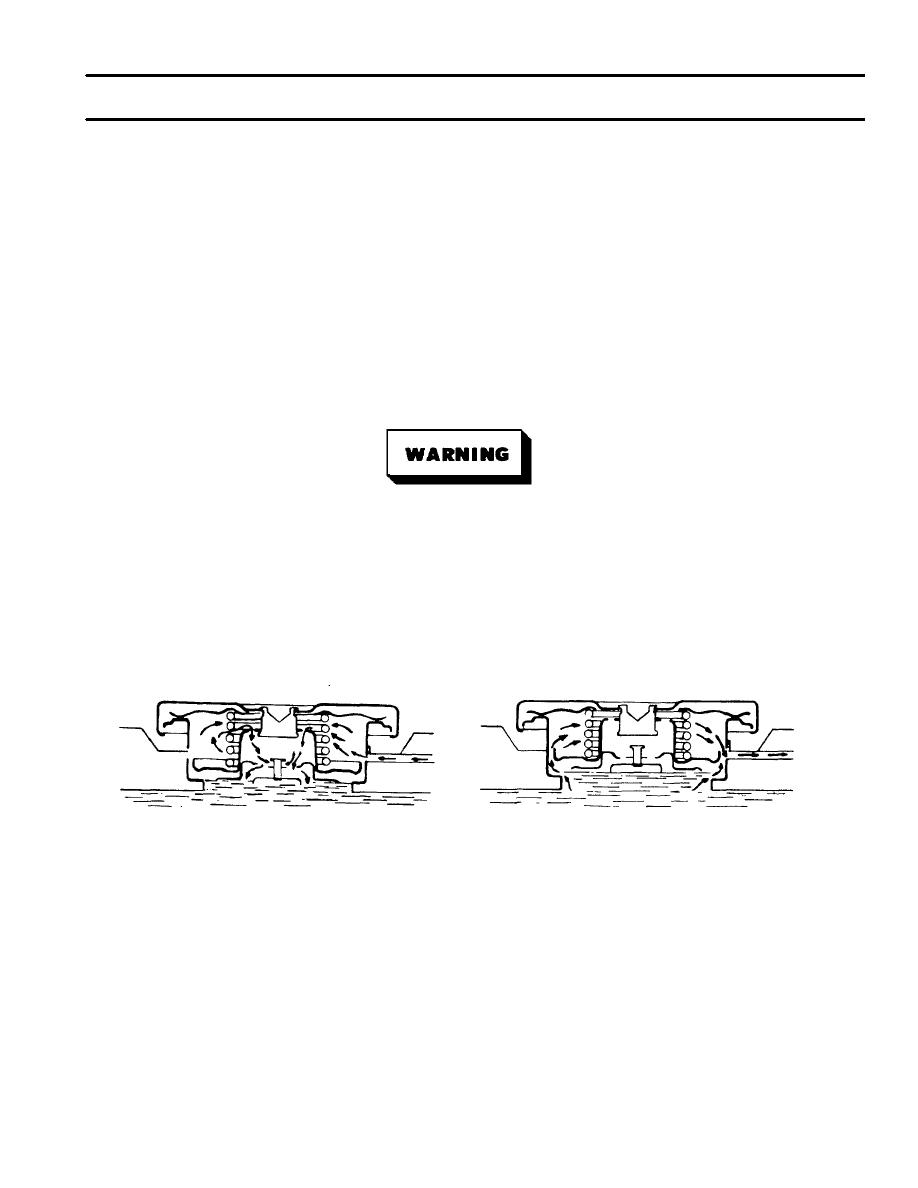

c. The expansion tank has a pressure control cap with a normally closed valve. The cap with a number 7

stamped on its top, is designed to permit a pressure of approximately seven pounds in the system before the

valve opens. This pressure raises the boiling point of the cooling liquid and permits somewhat higher engine

operating temperatures without loss of any coolant from boiling. To prevent the collapse of hoses and other

parts which are not internally supported, a second valve in the pressure cap opens under vacuum when the

system cools.

Always remove the expansion tank cap slowly and

carefully to avoid possible flash of hot cooling

liquid.

d. To ensure against possible damage to the cooling system from either excessive pressure or vacuum,

check both valves periodically for proper opening and closing pressures. If the pressure valve does not

open between 6-1/4 and 7-1/2 psi (43.1 and 51.7 kpa) or vacuum valve does not open at 5 to 8 Hg (34.5

to 55.2 kpa) replace cap.

3-584

|

||

|

||