| Tweet |

Custom Search

|

|

|

||

TM 55-1905-219-14-8

4-28. AIR CONDITIONING SYSTEM - MAINTENANCE INSTRUCTIONS (Continued).

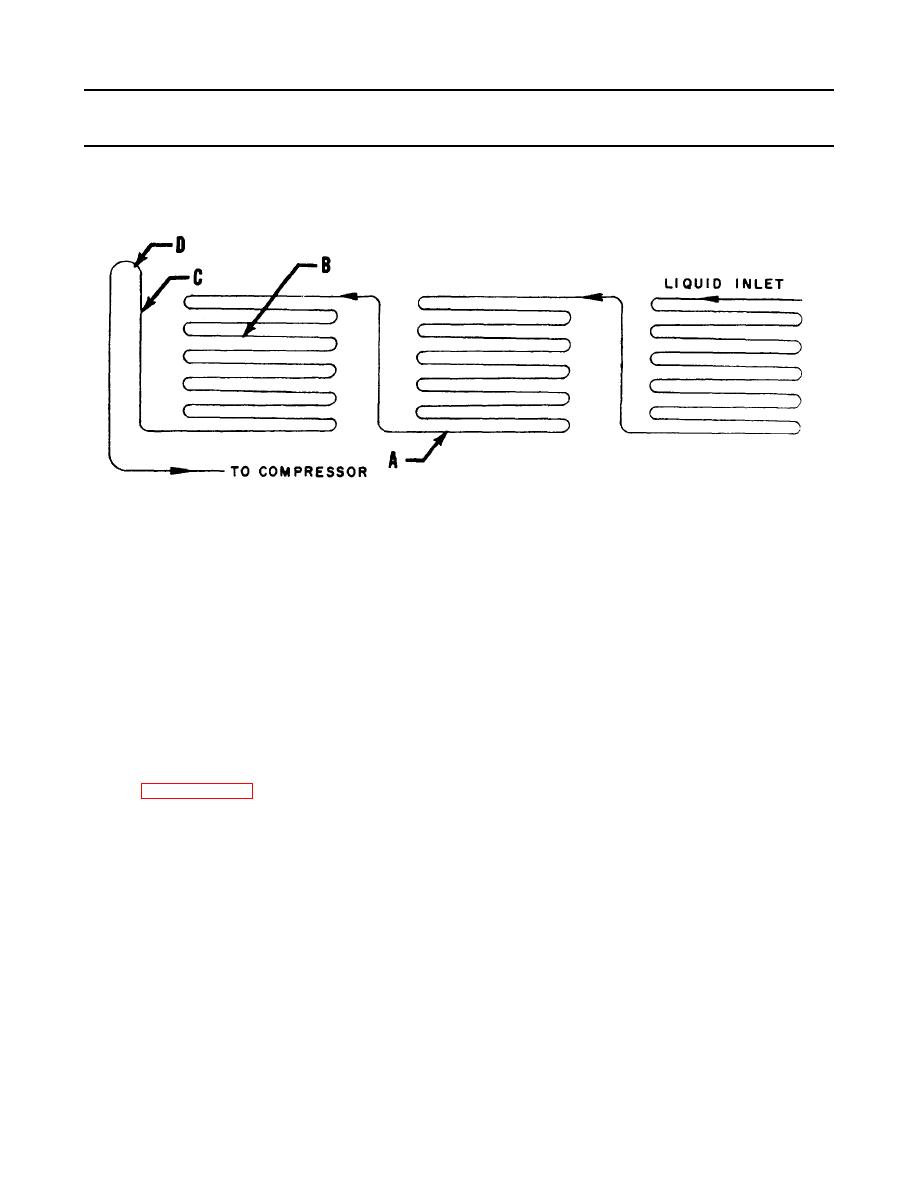

(d) To prevent an oil pocket at (A), liquid refrigerant in the coil should extend at least to point (B).

Riser line (C) is sized so that the velocity of the refrigerant suction gas will carry the oil up and over suction

loop (D).

Wetted Surface of Cooling Coil

(e) If necessary to adjust the expansion valve to eliminate an oil trap at (A), do it soon after

defrosting, before new frost has accumulated on the coils. At that time, it will be easy to determine the end of

the wetted portion of the coil, that is, how far liquid refrigerant extends in the coil. (A decided difference in the

rate of frost accumulation will exist in the area where the liquid refrigerant completes evaporating and becomes

a superheated gas.)

(3)

Compressor Oil Level and Oil Charge.

(a) After the compressor has been stopped for several minutes, the oil level in the compressor

crankcase should be about half-way up on the bull's-eye sight glass. During operation, the oil level will

be slightly lower but will appear higher when oil is foaming.

(b) Check the oil level hourly. Add or remove oil to bring level in crankcase to about the middle of

the bull's-eye sight glass during steady operating conditions. Follow procedures for adding or removing oil

given in paragraphs 4-28f(4) and 4-28f(5).

(c) The initial oil charge for the compressor is shown in table below, but it may be necessary to

charge additional oil, since the refrigerant will carry some oil to other parts of the system. Refer to paragraph 4-

28f(2).

4-846

|

||

|

||