| Tweet |

Custom Search

|

|

|

||

TM 55-1905-220-14-7

3-172.1. CRANSHAFT BEARINGS - MAINTENANCE INSTRUCTIONS (Continued).

LOCATION

ITEM

ACTION

REMARKS

INSPECTION (Cont)

journals in line with the journal oil holes. If this ridge is not removed before the new bearings are installed, then,

during engine operation, localized high unit pressures in the center area of the bearing shell will cause pitting of

the bearing surface. Also, damaged bearings may cause bending fatigue and resultant cracks in the crankshaft.

Refer to Paragraph 3-172.2 under Crankshaft Inspection for removal of ridges and inspection of the crankshaft.

d. Do not replace one main bearing shell alone. If one bearing shell requires replacement, install both new

upper and lower bearing shells. Also, if a new or reground crankshaft is to be used, install all new bearing

shells.

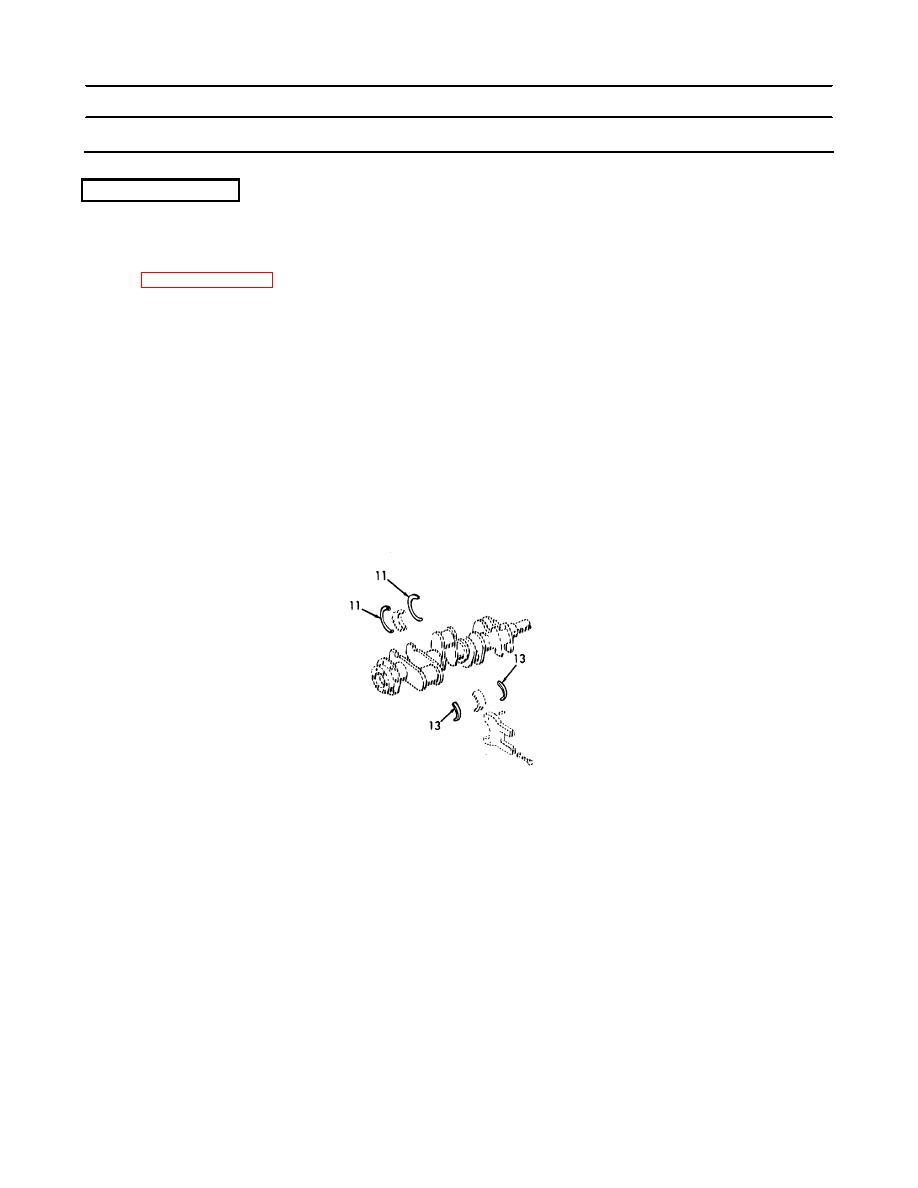

5. Upper

Thrust

Inspect.

If the washers

and

washers

are scored or

lower

(11 and

worn excessive-

thrust

13)

ly or the crank-

washers

shaft end play

is excessive,

they must be

replaced. Im-

proper clutch

adjustments can

contribute to

excessive wear

on the thrust

washers. In-

spect the crank-

shaft thrust

surfaces. If

after dressing

or regrinding

the thrust sur-

faces, new

standard size

thrust washers

do not hold the

crankshaft end

play within the

specified lim-

its, it may be

necessary to

install an over-

size thrust

3-2957

|

||

|

||