| Tweet |

Custom Search

|

|

|

||

TM 55-1905-220-14-7

3-172.1. CRANSHAFT BEARINGS - MAINTENANCE INSTRUCTIONS (Continued).

LOCATION

ITEM

ACTION

REMARKS

INSTALLATION (Cont)

washers

sharply with a soft

(2)

hammer to seat the

bearing caps.

3. Tighten bolts

Torque to 180-

uniformly.

190 ft-lb

(244.1-257.6

Nm).

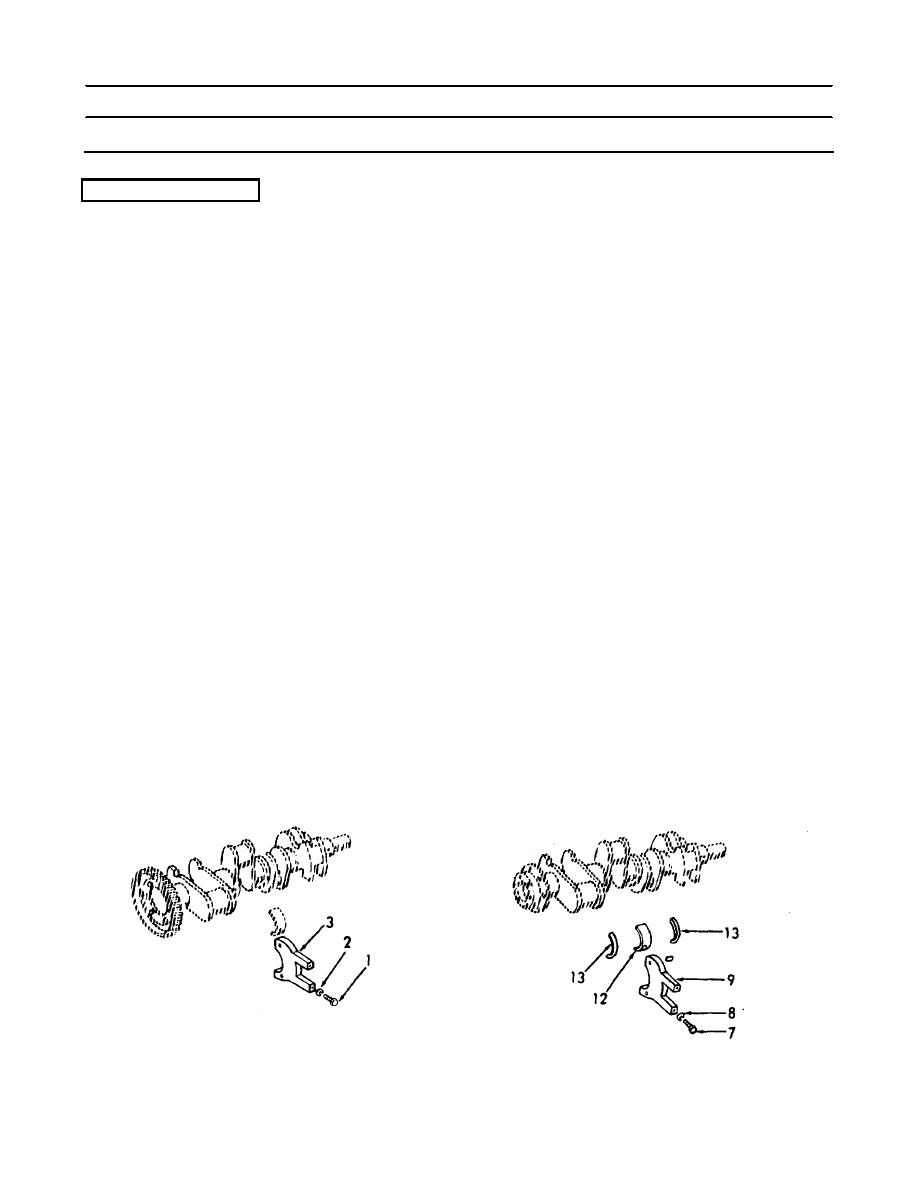

11. Bearing

a. Bolts

Place a small quantity

Use Interna-

cap

(7)

of compound on threads

tional Compound

number

and the bolt head con-

#2 or equiva-

4

tact area.

lent.

b. Bearing

Position on crankshaft.

caps

(9)

c. Bolts

Install.

Torque to 70-75

(7)

ft-lb (94.9-

and

101.7 Nm).

lock-

1. Install and draw up

washers

tight.

(8)

2. Rap the bearing cap

To seat the

sharply with a soft

bearing caps.

hammer.

NOTE

If the bearings have been installed properly, the crankshaft will

turn freely with all of the main bearing cap bolts drawn to the

specified torque.

3-2961

|

||

|

||