| Tweet |

Custom Search

|

|

|

||

TM 55-1905-220-14-8

4-7.7. CRANKSHAFT AND PISTON - MAINTENANCE INSTRUCTIONS (Continued).

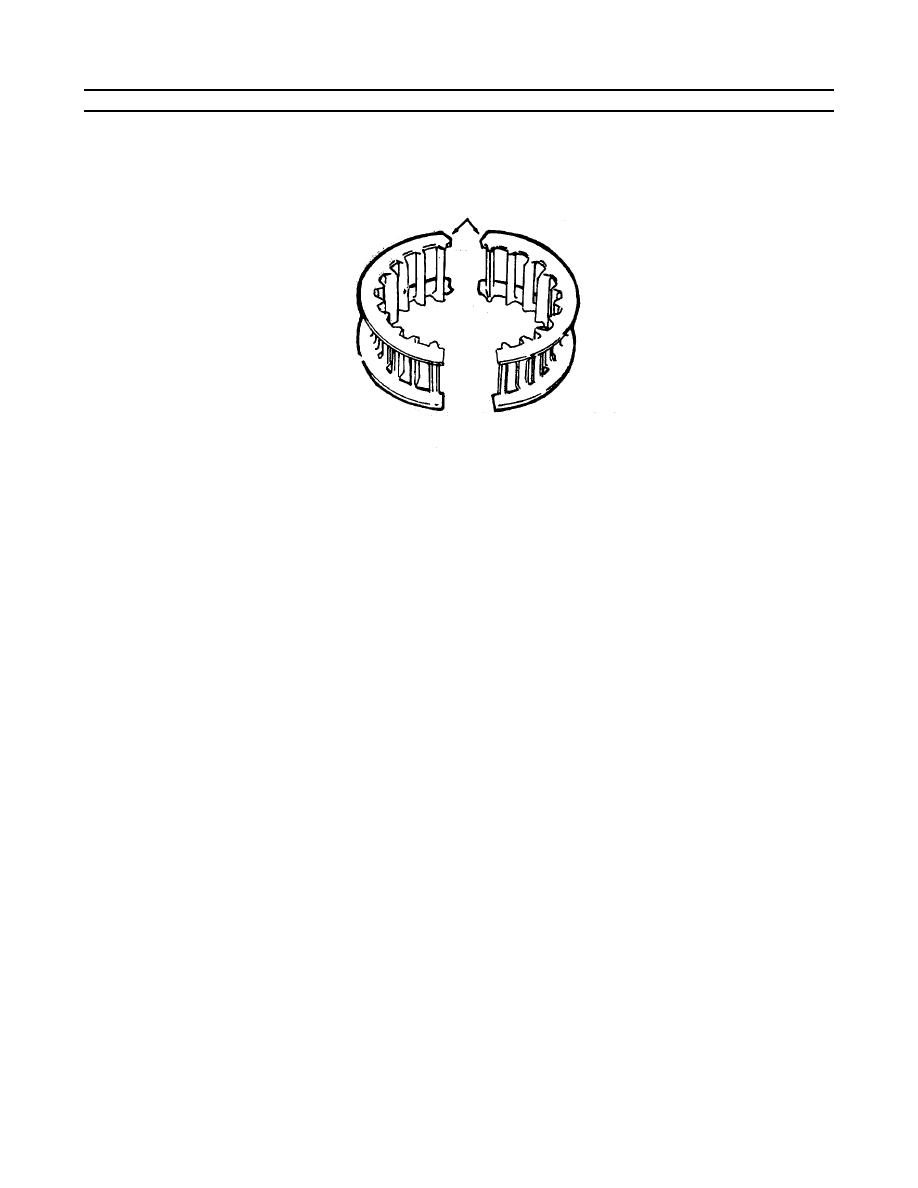

c. The connecting rod roller bearing retainers are machined as one piece and later split by sawing to permit

assembly on the crankpin, and proper matching is required. The retainer halves are not interchangeable and

must at all times be kept together to prevent intermixing during the repair procedure. Neither can they be

placed or turned end for end on assembly. The figure illustrates the ground ends.

d. The outer and center main crankshaft bearings are the caged needle roller type; the inner main bearing is

of the double row ball type and it is therefore necessary to provide seals to prevent loss of crankcase

compression. Lip-type seals are provided on outer end of the crankshaft and a grooved bronze bushing is

installed adjacent to the center and inner bearing. A rubber O-ring is provided between the outer bearing

assembly and the crankcase support.

4-201

|

||

|

||