| Tweet |

Custom Search

|

|

|

||

TM 55-1905-221-14-3

6-16

PROPELLER, PROPELLER SHAFT, AND STUFFING BOX (Continued)

LOCATION/ITEM

ACTION

REMARKS

REPAIR (Cont)

NOTE

The use of silver brazing alloy or any other low temperature brazing alloy is not

erosive action of high velocity water.

(1) Repair of Cavitation Pits.

Cavitation pits can be weld-

filled, using any approved

method.

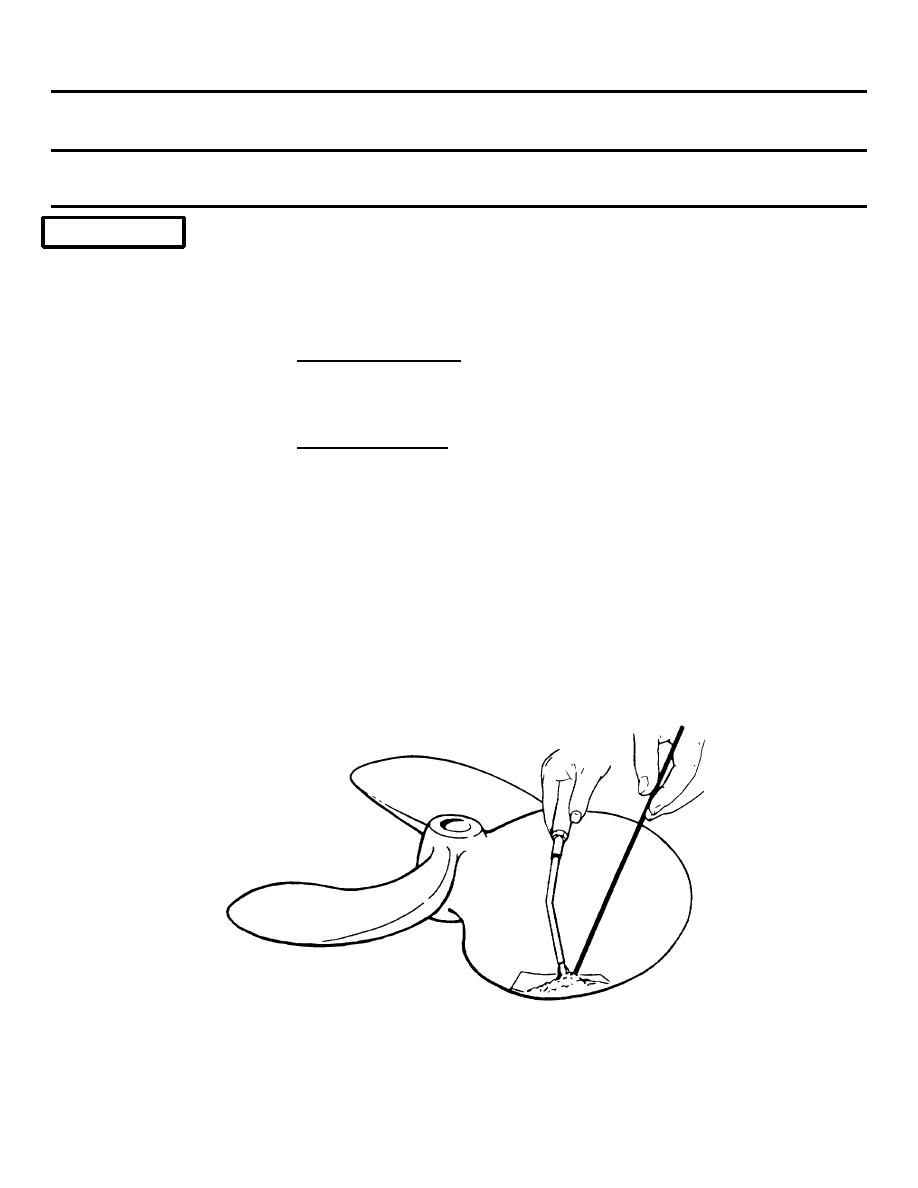

(2) Repair of Blade Edges.

Broken propeller edges can be

replaced by welding a corres-

ponding edge from a discarded

propeller, see figure below.

Cracks are ground or cut open

and then welded together.

The entire crack must be

round out or it will start

cracking again. If necessary,

blades can be built up with

the same welding rods used in

the process of welding.

Small notches in the edges

are sometimes filled by

welding.

6-179

|

||

|

||