| Tweet |

Custom Search

|

|

|

||

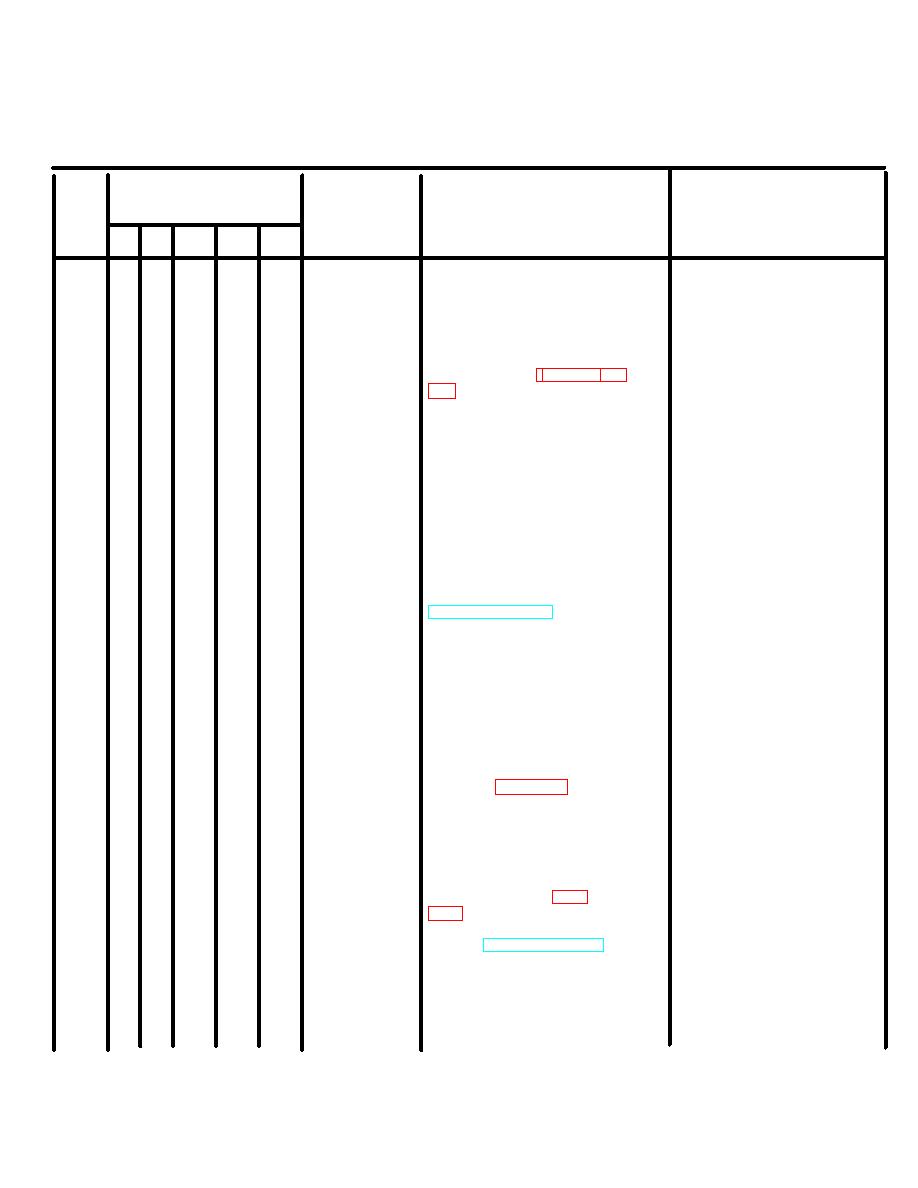

TM 55-1905-222-14

Operator Preventive Maintenance Checks and Services (Continued)

B-Before

A-After

M-Monthly

D-During

W-Weekly

Equipment is Not

PROCEDURES

INTERVAL

ITEM

Item To Be

Ready/Available If:

Check for and have repaired

NO.

Inspected

or adjusted as necessary

B

D

A

W

M

4

Ramp Lock-

Inspect cylinders for leaks and

Cylinders do not re-

ing Hydrau-

tighten connection as neces-

lease latch hooks.

Iic Cylinders

sary Wipe oil and dirt from cyl-

inders using dean rags Re-

place and repair (para 5-21 and

6-9), as necessary

5

Ramp

Fill primary drive assembly

Winch

through port "Q" with hydraulic

Hydraulic

oil (MIL-H-17672) Item 12, Ap-

Motor

pendix E.

6

Ramp

Inspect winch to ensure it oper-

Winch is not capable of

Winch

ates freely with no binding In ei-

operating ramp

ther direction Check to see if

winch vibrates during operation,

tighten mounting bolts

Apply tow or three shots of

grease to fittings on lever arm.

Fill final drive assembly to the

level of the filler plug (refer to

L055-1905-222-12) Wipe

winch dean with clean rag.

Ramp

Assembly

7

a. Ramp

Inspect ramp for dents, cracks,

Ramp does not provide

rust, or other damage that will

watertight integrity

inhibit safe functioning of the

while underway.

ramp Weld, scrape to remove

rust, then prime and paint as

necessary

Replace ramp if

necessary (para. 5-25)

b Cables

Inspect cables and sheaves for

Cable has kinks,

and

wear and serviceability Pay out

hockddes and broken

Sheaves

cable and check for kinks,

wires

hockles, and broken wires

Check sheaves for frictional

Sheaves will not rotate

wear and freedom to spin. Re-

or hold cable to guide it

place as necessary (para

Lubricate cables and sheaves

(refer to L055-1905-222-12)

Change 6

2-19

|

||

|

||