| Tweet |

Custom Search

|

|

|

||

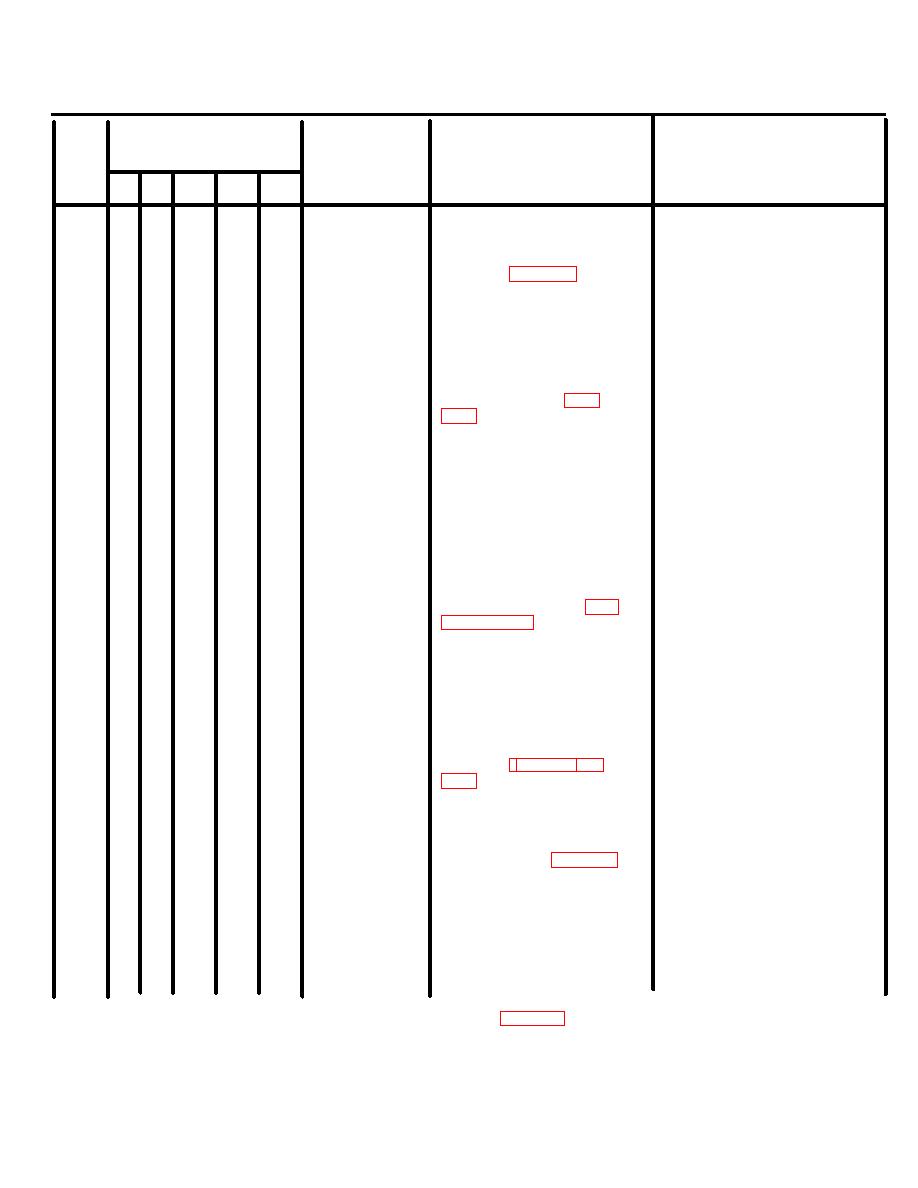

TM 55-1905-222-14

Operator Preventive Maintenance Checks and Services (Continued)

Equipment is Not

PROCEDURES

INTERVAL

Item To Be

ITEM

Ready/Available If:

Check for and have repaired

Inspected

NO.

or adjusted as necessary

B

D

A

W

M

42

Accumulator

Inspect accumulator and gauge

connections for leaks or dam-

age Replace accumulator as

necessary (para 5-45) Make

periodic checks to ensure that

accumulator retains pressure.

43

Reservoir

Check tank level indicator pen-

Reservoir is low or

and Filter

odically Add oil as needed

empty

Check filter for leaks and dirty

element condition, replace ele-

ment as necessary (para

44

Control

Check control valve and hy-

Valve

draullc connections for leaks or

damage Ensure valve functions

properly In local, remote and

manual modes.

45

Starting Mo-

Inspect motor and connections

Starting motor cannot

tor

for leaks or damage. Tighten

crank engine.

hose connections and mounting

hardware as necessry Replace

or repair as necessary (para

46

Hand Pump

Inspect hand pump and connec-

Hand Pump will not op-

tons for leaks or damage.

erate

Check periodically to ensure

that pump is capable of charg-

ing system Check to make sure

that the Hand Pump is free of

air Replace or repair pump as

necessary (para 5-49 and

47

Strainer

Inspect strainer for leaks. Tight-

en drain plug and fuel connec-

tons Clean strainer monthly or

every 500 hours (para. 3-14)

48

Fuel Filter/

Inspect filter and connectons

Filter leaks Bowl is

Water Sepa-

for leaks

cracked or broken.

rator

Inspect the clear bowl for accu-

Filter Is not properly

mulation of filtered deposits

mounted/secured so as

Check gauge reading, 10-15 In

to put no additional

Hg vacuum is an Indication that

strain on the fuel lines

bowl is to be cleaned Clean as

required (para 3-16)

Change 6 2-33

|

||

|

||