| Tweet |

Custom Search

|

|

|

||

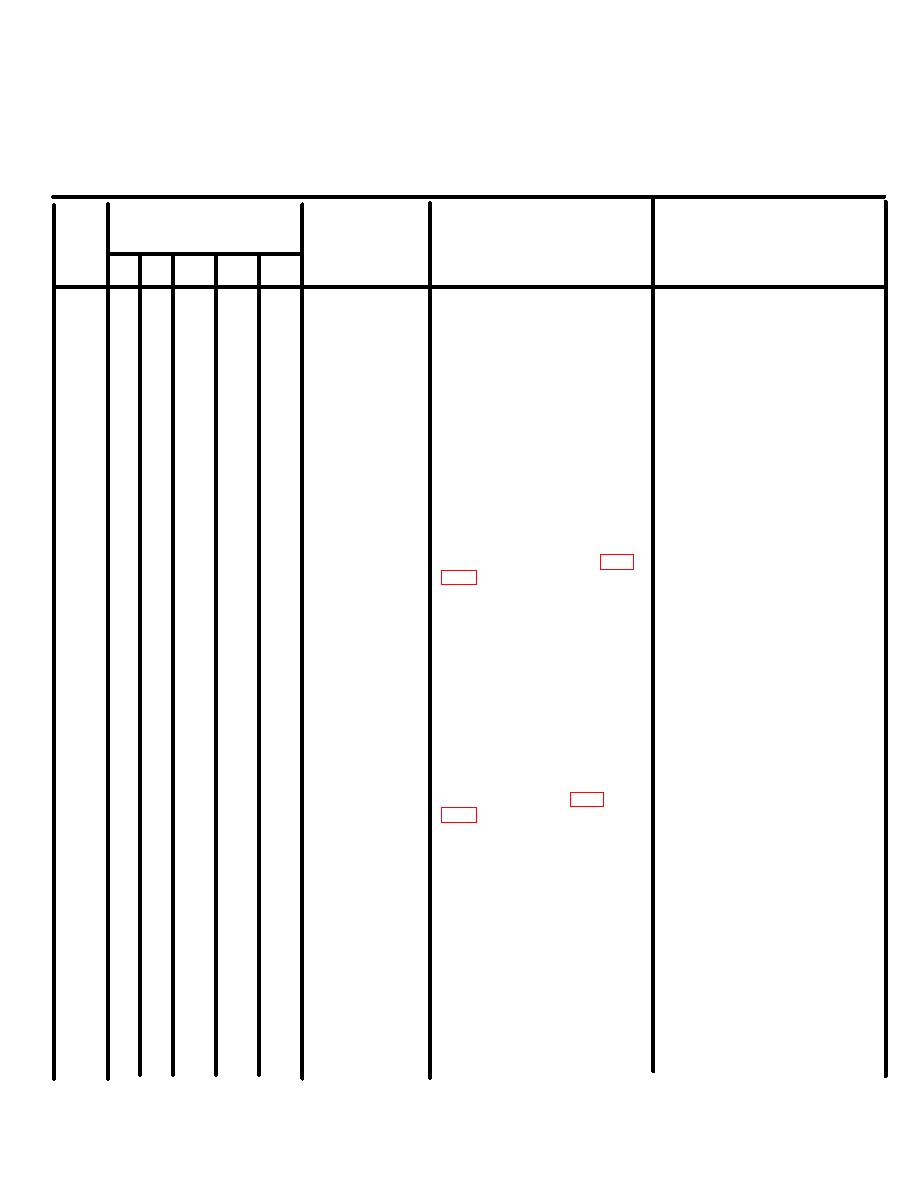

TM 55-1905-222-14

Operator Preventive Maintenance Checks and Services (Continued)

B-Before

A-After

M-Monthly

D-During

W-Weekly

Equipment Is Not

PROCEDURES

INTERVAL

Item To Be

ITEM

Ready/Available If:

Check for and have repaired

Inspected

NO.

or adjusted as necessary

B

D

A

W

M

Tools/BII

Inventory all BilI tools to ensure

accountability and serviceability

of all items For Bll, see Approx

C. Use SB

5180-90-CL-N55-HR to inven-

tory tools.

50

Expansion

Inspect sight glass for coolant

Tank

level (1/2 full when cold) Add

coolant as necessary Check

antifreeze condition with

hydrometer.

Check tank for cracks, leaks or

corrosion Weld cracks and re-

pair valves as necessary (para

Exhaust

System

51

Piping and

Inspect exhaust pipng for ex-

Lagging

haust leaks, or other damage.

Make sure adequate thermal

protection is positioned for dan-

gerously exposed areas Re-

place lagging if necessary.

52

Mufflers

Muffler leaks or other-

leaks Check raw water connec-

wise damaged

bon for leaks Inspect muffler for

signs of corrosion. Replace or

repair as necessary (para

Hull Below

Waterline

53

Stuffing Box

Inspect stuffing box for condi-

tion of packing and amount of

leakage Ensure all bolts are

present and snug Adjust stuff-

ing box while underway as nec-

essary. Check gland for excess

heat by placing hand on gland

after adjustment. Check flex

hose & clamps for proper Instal-

lation and deterioration

Change 6 2-35/(2-36 blank)1

|

||

|

||