| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-10

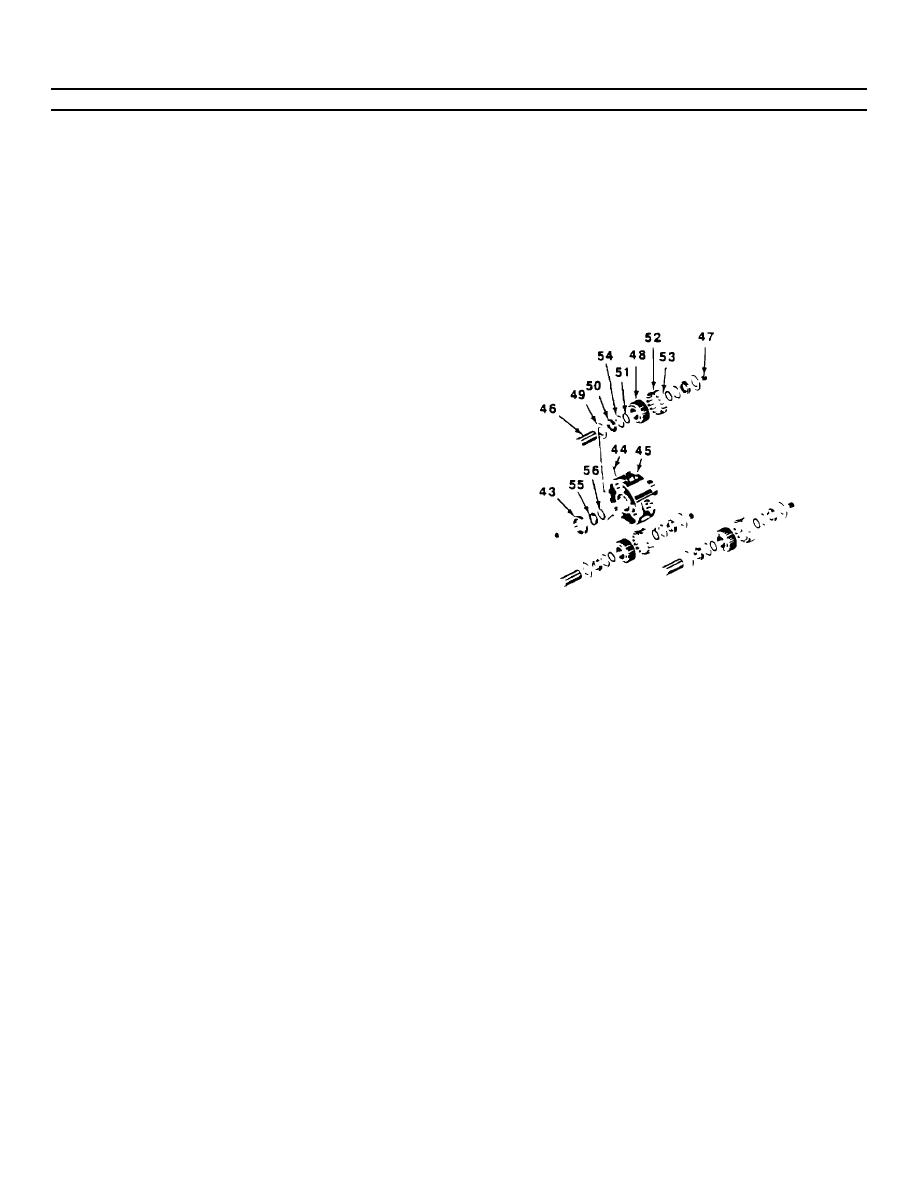

REPAIR RAMP WINCH (Continued).

g. Inspect the roller bearings (50) for freeness of

rollers. Check for pits, broken rollers or

excessive wear, also damage or excessive

wear on the bronze bearing cage or flange, and

replace the bearings (50) if any of these

conditions exist.

h. Check the cam locks (52 and 53) for wear at

the points where they contact the planet pin

(46) and gear (48). If flats are worn on the cam

locks at these points, they will require

replacement.

i.

Check the gear spacers (49) for flatness and

wear.

j.

Check thrust plug (47) for wear on flange end.

If flange has worn down to 1/32" thick, the

thrust plugs (47) will require replacement.

k. Check thrust pad (55) for wear on slotted face.

If wear exceeds 1/8", replace. Original

thickness of the thrust pad (55) was 0 562".

l.. Check bushing (43) for wear on the bore. If

flange has worn to 1/32" thick or if bore has

worn more than 010, replace the bushing (10).

Original bore was 2.253".

NOTE

all these parts must be replaced at the same time.

6-48

|

||

|

||