| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-10

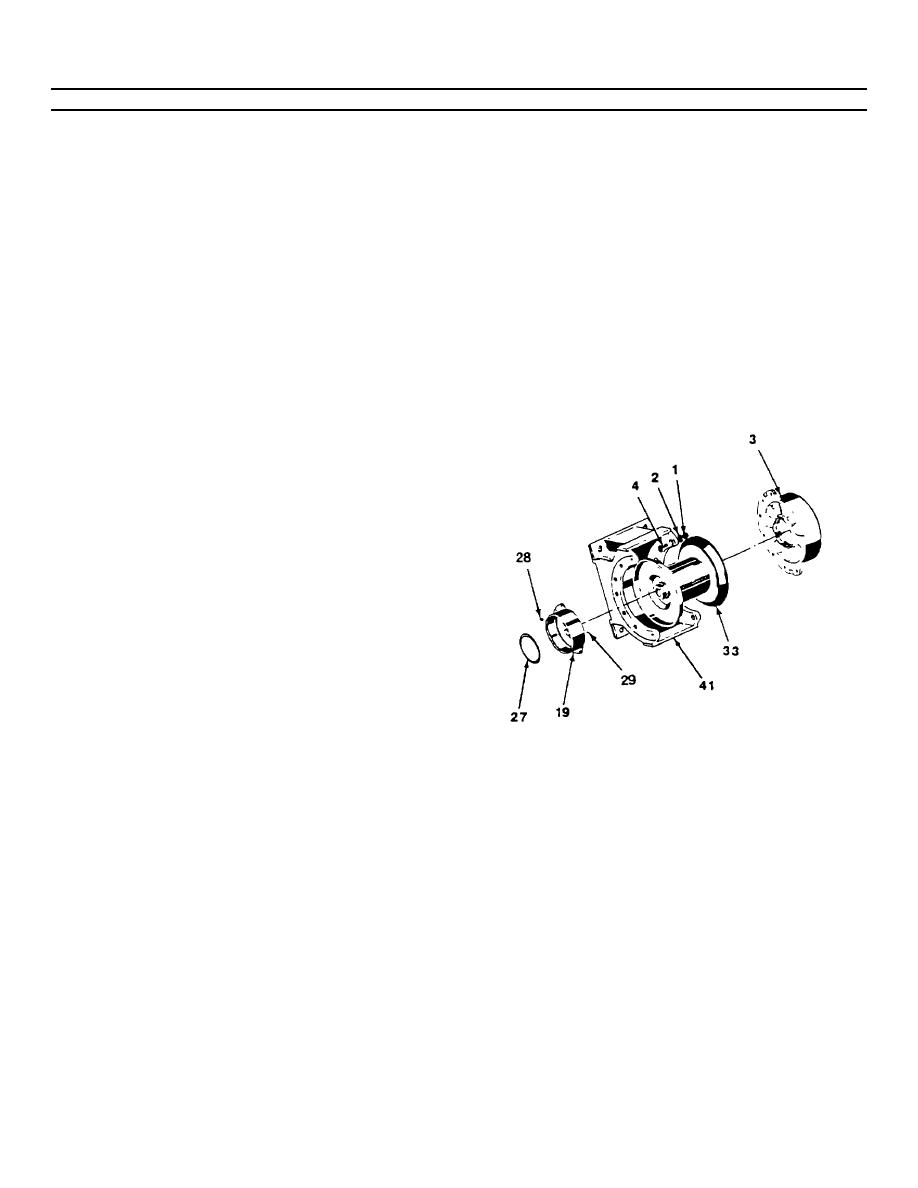

REPAIR RAMP WINCH (Continued).

e.

Tap the drum assembly at the splined end

of the drum assembly down until the snap

ring on the bearing at the splined end of the

drum is properly seated on the end of the

final housing bore

There will be

approximately 1/16 inch clearance between

the final housing and the end of the drum

flange when the bearing snap ring is

seated.

NOTE

If the drum has a flange diameter larger than standard, steps a through e can not be

used. In this case, install drum assembly by nesting it Into the winch base.

f.

Take the primary housing (19) and install the

snap ring (27) in the snap ring groove that is

closest to the large open end of the housing.

g.

Pilot the primary housing (19) over the bearing

on the plain end of the drum (non-splined end)

so that the dowel bolts will locate in the flange

of the primary housing on the drum until its

flange contacts the winch base.

h.

Secure the primary housing (19) to the winch

base (41), using seven lockwashers (2) and nuts

(1) on the dowel bolts (4). Torque load nuts (1)

to 75 pounds foot.

i.

Install pipe plugs (28 and 29) on the primary

housing (19).

6-59

|

||

|

||