| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-14

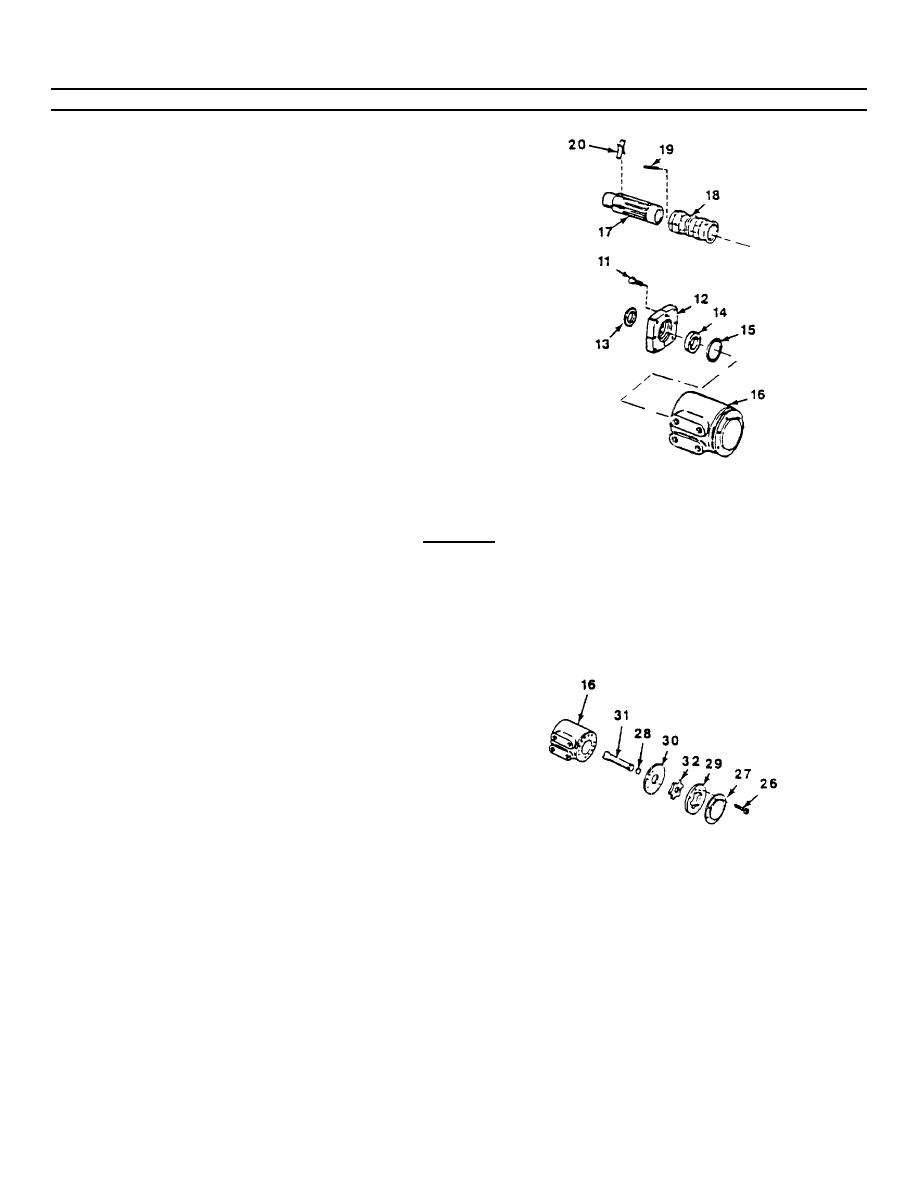

REPAIR HELM UNIT (Continued).

f.

Align spring slots of control spool (17) and

sleeve (18) and install spring set (20) using

spring installation tool J600057.

g.

Install centering pin (19) through control spool

and sleeve assembly

h.

Install control spool and sleeve assembly in

housing (16) so that the splined end of the spool

enters first With the control spool and sleeve

assembly. in this flush position, check for

free rotation within the housing.

i.

Install new preformed packing (15) and bushing

(14) on housing (16).

j.

Install oil seal (13) in counter bore of mounting

plate (12) and install mounting

plate on

housing (16) Secure with four capscrews

(11). Torque evenly to 250 pound-inches.

2.

ASSEMBLE METERING SECTION.

CAUTION

Alignment of the cross slot in the drive with valleys between the teeth of the meter

gear star determines proper valve timing of the unit. There are 12 teeth on the

spline and 6 pump teeth on the star. Alignment is exactly right in 6 positions

and exactly wrong in 6 positions. If the parts slip out of position during this part of

the assembly, repeat until you are certain that correct alignment is obtained.

a.

Place the plate (30) over the housing (16)

so that both holes in the plate align with the

tapped holes in the housing

Place the

meter gear (29) on the assembly as the bolt

holes align

6-78

|

||

|

||