| Tweet |

Custom Search

|

|

|

||

TM 55-1905-222-14

6-23

REPAIR PROPELLER AND PROPELLER SHAFT.

INITIAL SETUP

Tools:

Equipment Conditions:

Tool Kit, Mechanic's, Rail

Reference

and Marine

removed.

Blacksmith's Forge

Anvil

Machine, Welding

REPAIR

1. REPAIR PROPELLER.

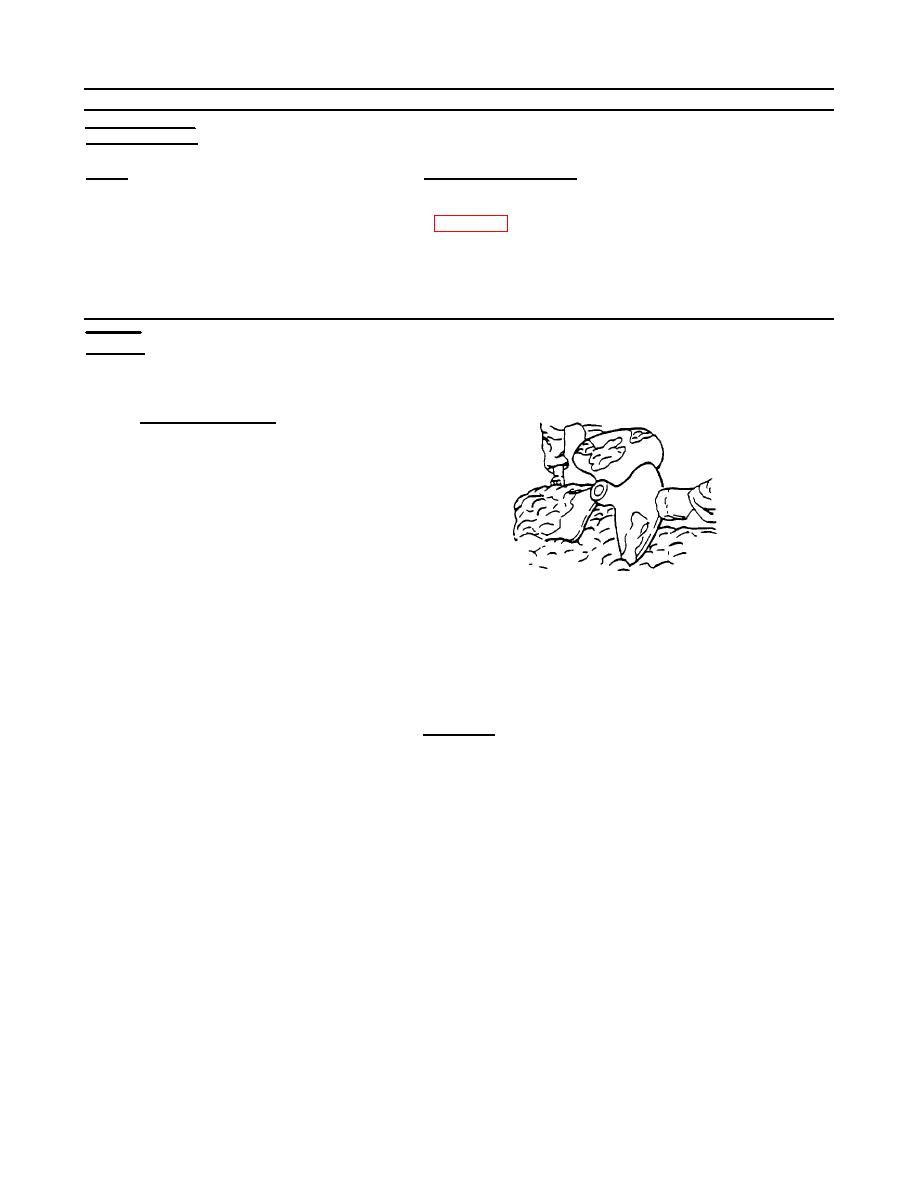

a. Heating Propellers.

Small bends or

depressions in bronze propellers can be

straightened while the propeller is cold.

Because cold working hardens bronze,

large bends or irregularities must be

repaired using heat to prevent cold cracks

from occurring. When heat is used, heat

propeller to a dull red color in a forge or

with a gas flame. For overall heating

where large surfaces are involved, the

forge is faster and gives a more uniform

application of heat. Figure at right shows

a propeller being heated with a forge. For

small or localized repairs, a gas flame

should be used.

CAUTION

Bronze becomes weak at high temperatures and the propeller, if struck, can sag or break.

Exercise care when handling or repairing a heated propeller.

6-121

|

||

|

||