| Tweet |

Custom Search

|

|

|

||

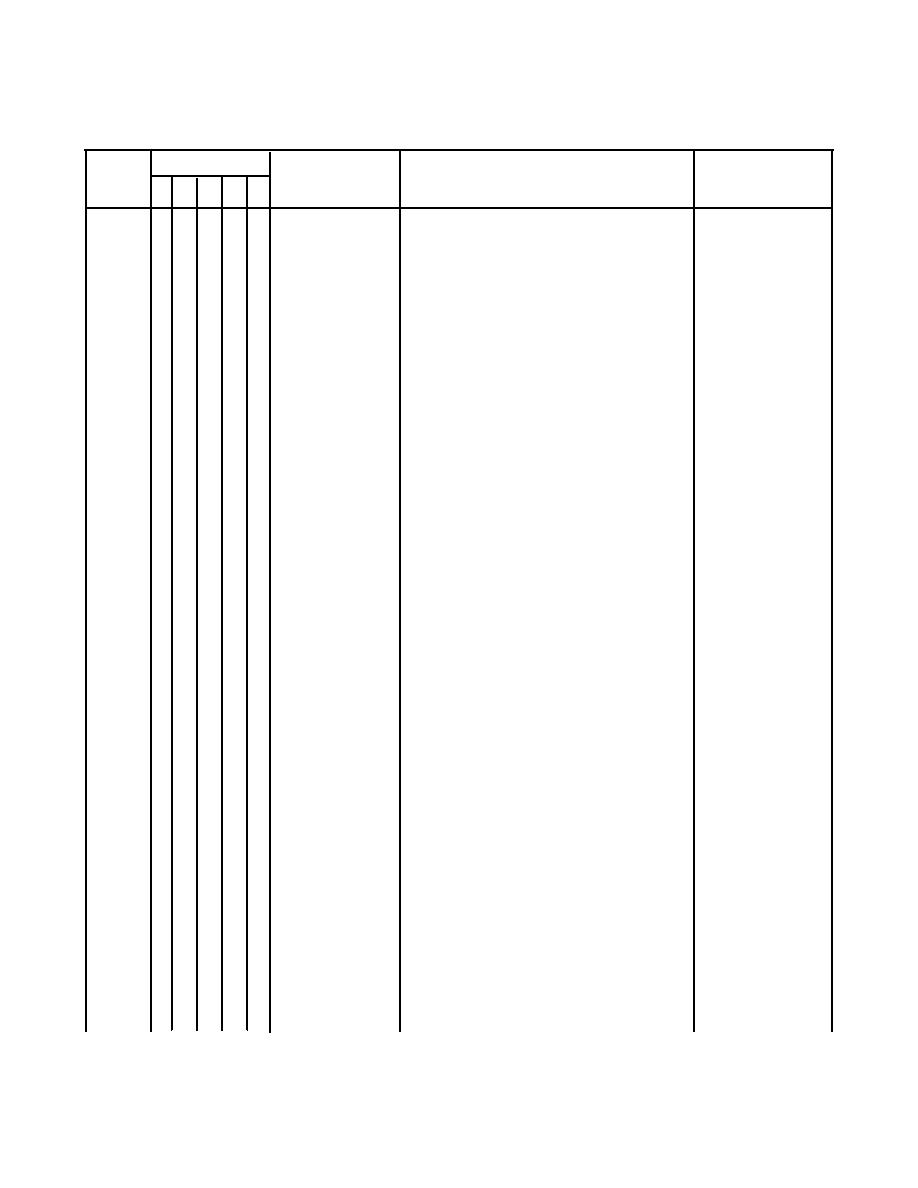

TM 55-1905-223-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Service - CONT

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

PROCEDURES

EQUIPMENT IS

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

NOT READY/

NO

B

DA W M

INSPECTED

OR ADJUST AS NECESSARY

AVAILABLE IF:

15

500 Watt

Searchlight

(Port) -

continued

Visual y inspect for crack in

l

the quartz. If a crack is

detected. Refer corrective

action to unit maintenance.

Reflector

Visually inspect for

l

tarnishing, dirt buildup, or

corrosion. Refer cleaning

requirements to unit

maintenance.

Front Cover

Visually inspect glass for

l

Class

defects or dirt buildup. Refer

corrective action to unit

maintenance.

Searchlight

Visually inspect the case for

l

damage, dirt buildu , or

p

corrosion. Refer corrective

action to unit maintenance.

16

Magnetic Compass Check heading on two known

Magnetic

l

ll

l

courses. Check deviation when-

compass is in-

ever metal structural changes

operative.

are made to vessel; or when

Compass will

electronic equipment is

not swing

added/removed. Check that

freely in

deviation card is up to date

gimbal.

and annual deviation card is

located in immediate vicinity

of compass. If damage is

found, refer to Unit

Maintenance.

17

Gyro Repeater

External

Visually inspect exterior

l

surfaces are clean. If dirty

clean with soft cloth.

2-220

|

||

|

||