| Tweet |

Custom Search

|

|

|

||

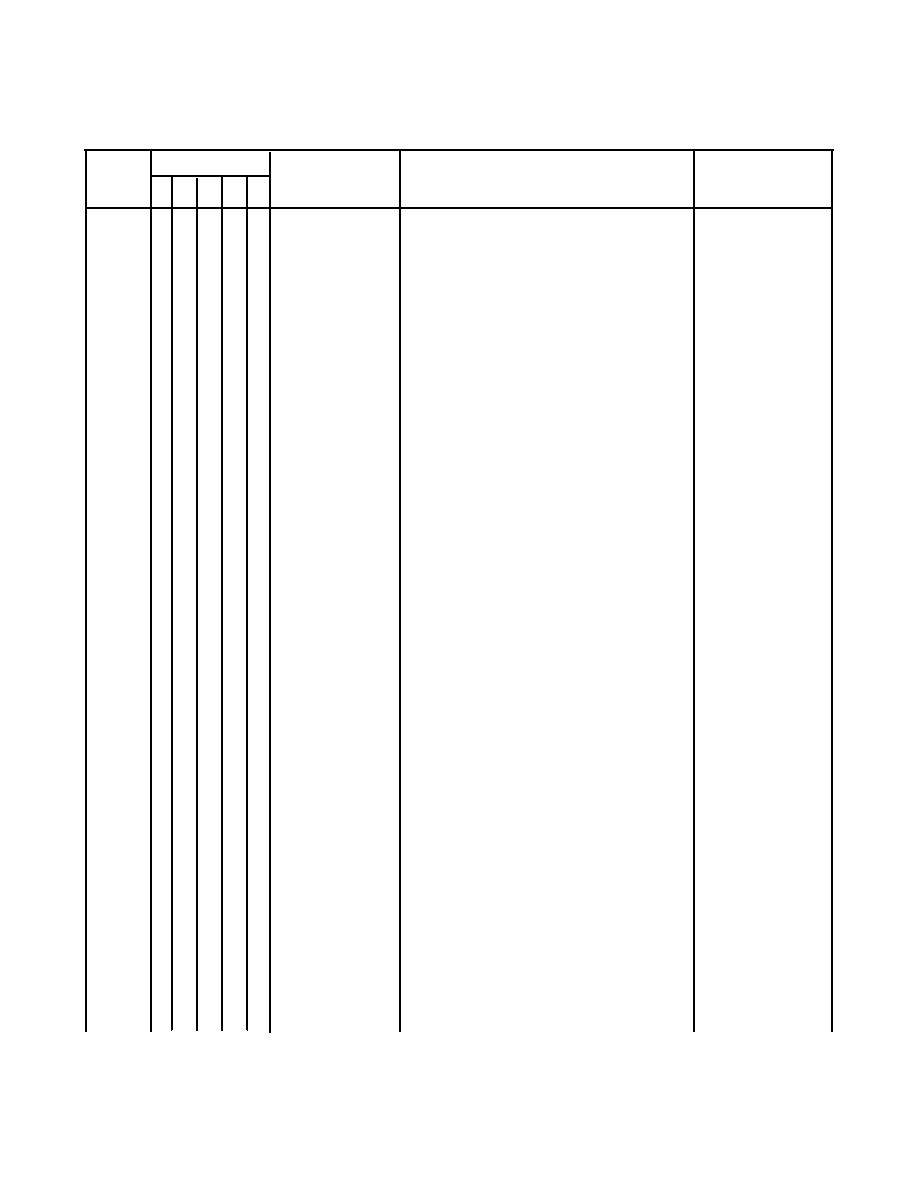

TM 55-1905-223-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Service - CONT

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

PROCEDURES

EQUIPMENT IS

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

NOT READY/

NO

B

DA W M

INSPECTED

OR ADJUST AS NECESSARY

AVAILABLE IF:

83

Compressed Air

Subsystem -

continued

AIR RCVR

Gauge should read 200 psi.

Pressure

NO 1 PRESS Gauge

greater than

200 or less

than 180 psi.

SYSTEM PRESS

Gauge should read 125 psi.

Pressure

Gauge

greater than

125 or less

than 110 psi.

CPRSR DISCH

Gauge should read 200 psi.

Pressure

PRESS Gauge

greater than

200 or less

than 180 psi.

84

Propeller and

Check for unusual vibrations.

Shaft is

Propeller Shaft

misaligned or

(Port)

bent, propeller

blades are bent

or damaged or

cutlass bearing

is excessively

worn.

85

Reduction Gear

Check the reduction gear unit

Debris, foreign

(Port)

for debris, foreign objects and

objects remain

loose or broken fittings.

wedged or

Refer problems to Unit

lodged in

Maintenance.

components.

NOTE

Inspection of the reduction

gear unit should be

accomplished prior to startup

operational checks of the main

propulsion engines.

Check for leaks

Class III

leaks.

2-255

|

||

|

||