| Tweet |

Custom Search

|

|

|

||

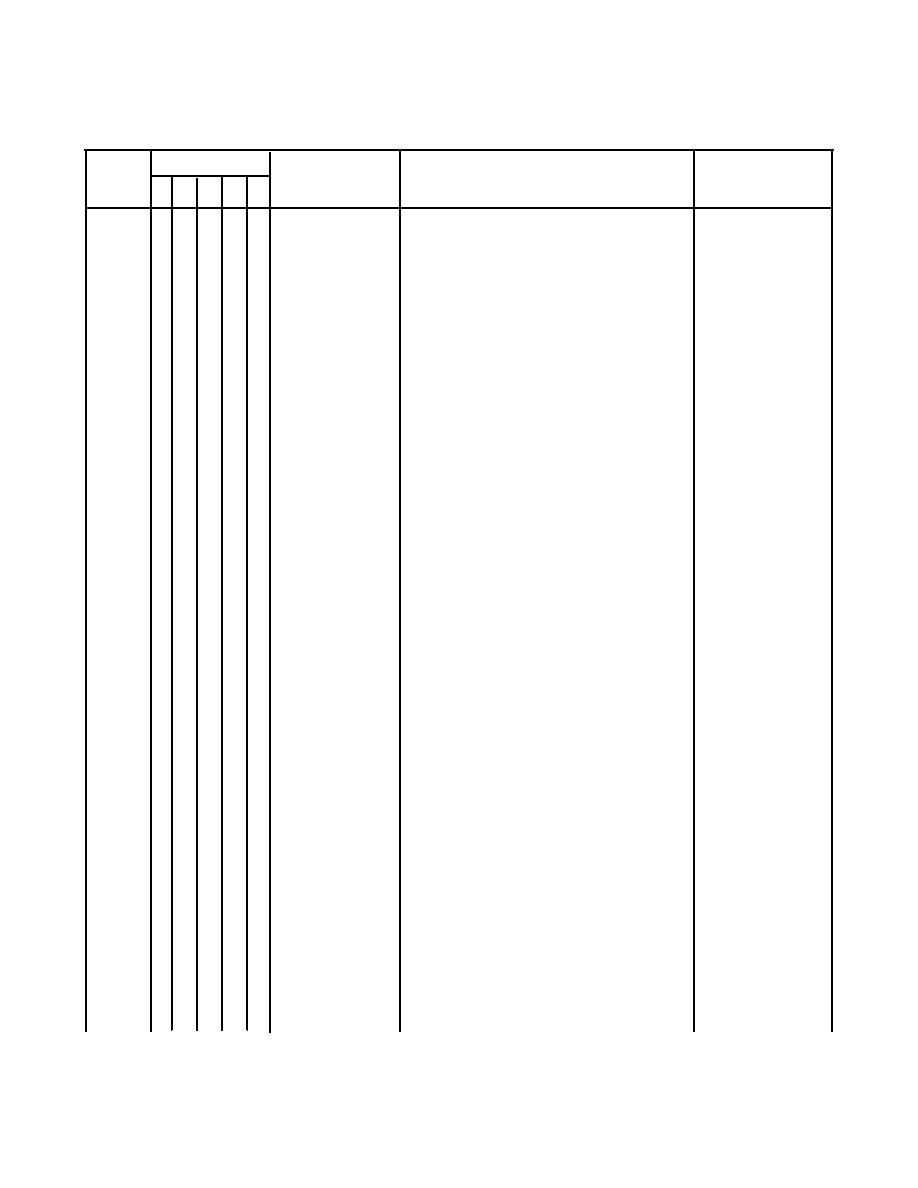

TM 55-1905-223-10

Table 2-2. Operator/Crew Preventive Maintenance Checks and Service - CONT

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

PROCEDURES

EQUIPMENT IS

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

NOT READY/

NO

B

DA W M

INSPECTED

OR ADJUST AS NECESSARY

AVAILABLE IF:

101

Main Propulsion

Check the engine for debris,

Debris, foreign

Engines (STBD)

foreign objects and loose or

objects wedged

broken fittings. Refer

or lodged in

problems to unit maintenance.

components.

Engine

Inspect engines, fuel injection

Accessories and

pumps and cooling pumps for

Connections

loose or damaged connections or

mountings.

Air Pressure

Check starting air pressure for

Low air

minimum of 125 psi reading.

pressure.

Oil Level

Check oil level between the add

and full mark on the engine

dipstick. Add oil if required.

Refer to LO 55-1905-223-12-2.

Cooling System

Check that engine coolant in

expansion tank is at full mark

in overhead sight glass.

Engine Idle

Tachometer should read 725-775

Idle speed

Speed

RPM.

below 725 or

above 775 RPM.

Fuel Oil

Check engine fuel supply.

Oil Pressure

Check gauge for proper oil

Oil Pressure

pressure (20 to 70 psi).

less than 20

psi or more

than 70 psi.

Cooling System

Check gauge for proper

Temperature

operating coolant temperature

more than

(160F to 203F).

180F.

Lube Oil

Check gauge for proper

Temperature

Temperature

operating oil temperature

more than

(175F to 195F)

195F.

2-271

|

||

|

||