| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

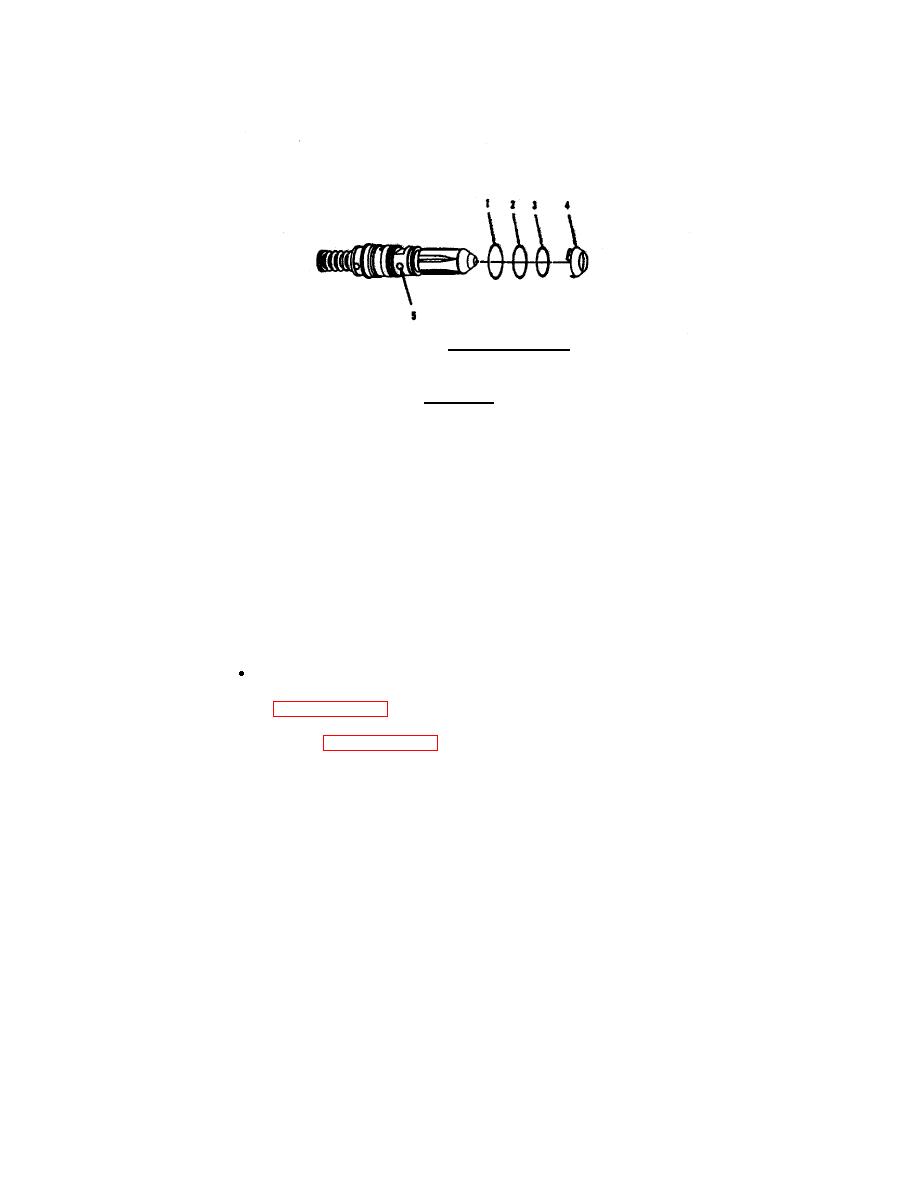

FIGURE 2-51. Injector Inspection.

CAUTION

Do not use a wooden tool to push the injector on the seat. Failure can result due to

splinters falling into the tappet.

d.

Start the injector (4) into the bore by hand and seat it with a quick, hard push.

NOTE

Remove the injector and inspect the preformed packings and seal seat if the

injector fails to seat properly.

e.

Place the hold-down clamp (2) over the injector body. Install two hexagon head capscrews (1). Do not

tighten.

f. Carefully insert the injector plunger link (3). Tighten the holddown capscrews alternately and evenly to

144 in.-lb (16 N m).

g.

Install rocker levers (paragraph 2-30).

h.

Adjust injectors and valves (paragraph 2-30).

2-120

|

||

|

||