| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

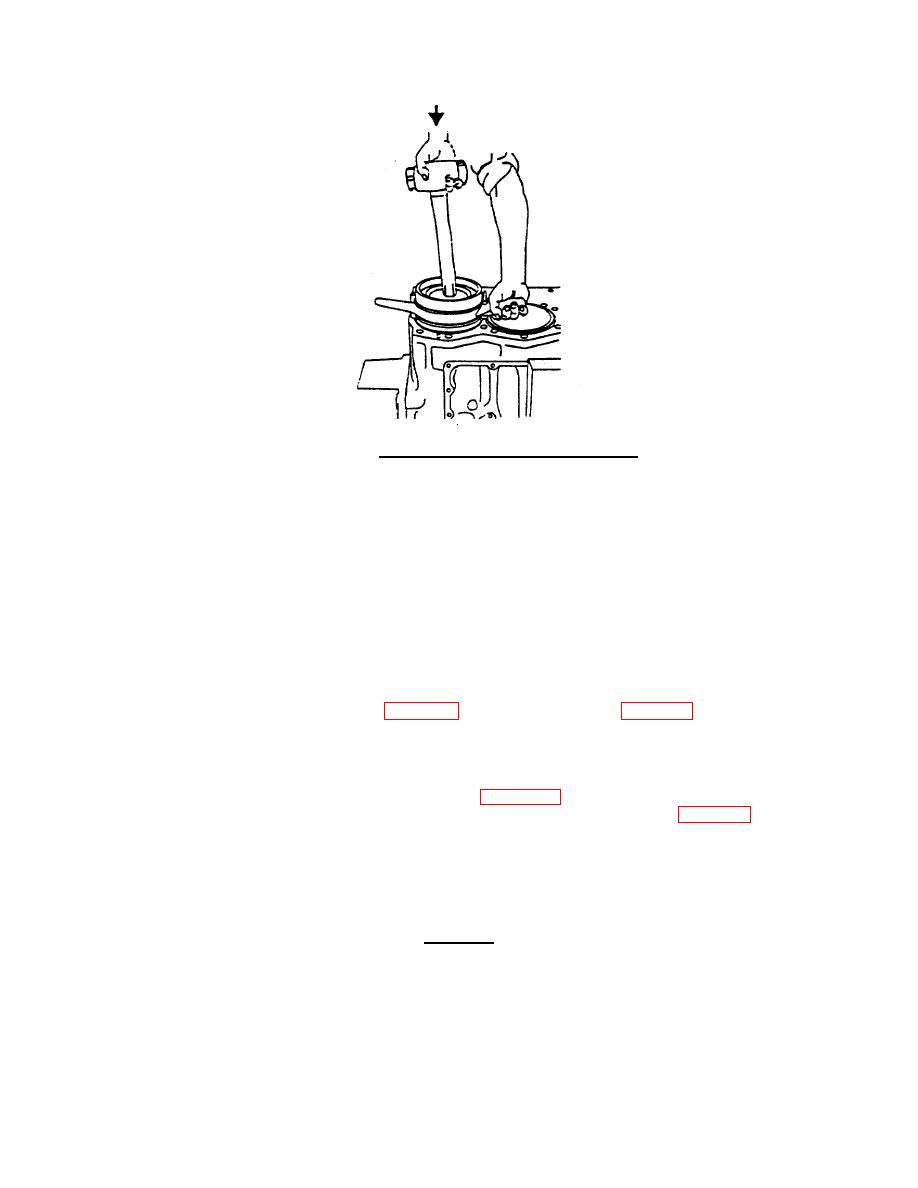

FIGURE 3-26. Piston and Connecting Rod Installation.

NOTE

After the piston and rod assemblies that share a

crankshaft journal are installed and the caps are pulled

to the rods, the crankshaft can be rotated. Rotating the

crankshaft so that the installed rods are on the bottom

will aid reaching the machine bolts. It is recommended

that the four rods that are connected to the two

crankshaft rod journals that have the same centerline be

installed, then the crankshaft rotated to the bottom.

c. Measure connecting rod bolt stretch.

(1) Tighten connecting rod bolts (3, FIG. 3-22) using the procedure in Table 3-5. Apply torque to both

bolts.

(2) Loosen both bolts (3).

(3) Position rod bolt checking fixture on rod bolt (FIG. 3-27). Ensure the fixture anvil is centered in

hole of the rod bolt and the figure contacts the head of the bolt as shown in FIG. 3-27.

(4) Adjust the fixture indicator to the 0.050 inch mark. Ensure that there is a minimum of 0.030 travel

remaining.

(5) Tighten indicator lock to maintain reading. Record reading as "First Bolt Zero."

CAUTION

Do not adjust indicator.

3-88

|

||

|

||