| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

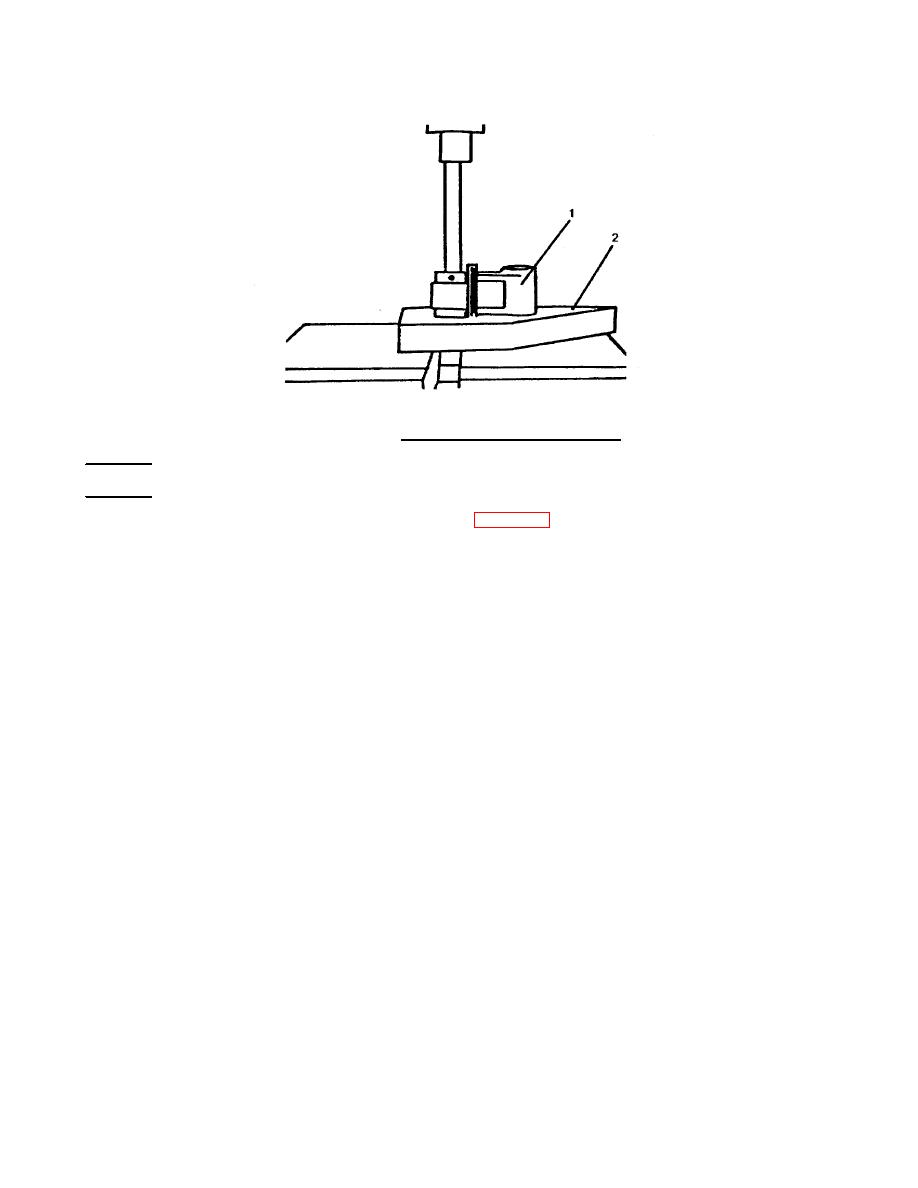

FIGURE 4-40. Cam Roller Pin Removal Socket.

REPAIR

a. Measure the outside diameter of the shaft (10, FIG. 4-39). If it is not between 0.8730 inch (22.174

mm) and 0.8740 inch (22.200 mm) or is scored or pitted, replace.

b. Check the inside diameter of the cam follower (7) for scratches, pitting, or scoring. Measure with an

inside micrometer. If it is not between 0.8750 inch (22.225 mm) and 0.887 inch (22.276 mm), replace.

c. Use compressed air. Ensure cam follower (7) oil holes are not blocked.

d. Check socket (6) for damage. If the socket must be replaced, perform the following:

NOTE

The roller (5) must be removed to allow access to

the socket removal hole.

(1) Use a brass drift to remove socket (6).

(2) Measure socket (6) outside diameter. Verify diameter is between 0.7505 inch (19.063 mm) and

0.7515 inch (19.088 mm).

(3) Measure cam follower (7) socket bore inside diameter. Verify diameter is between 0.7490 inch

(19.025 mm) and 0.7500 inch (19.050 mm).

(4) Compute press fit by subtracting the measurement in step (3) from the measurement in step (2).

Verify press fit is between 0.0005 inch (0.013 mm) and 0.0025 inch (0.064 mm).

4-33

|

||

|

||