| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

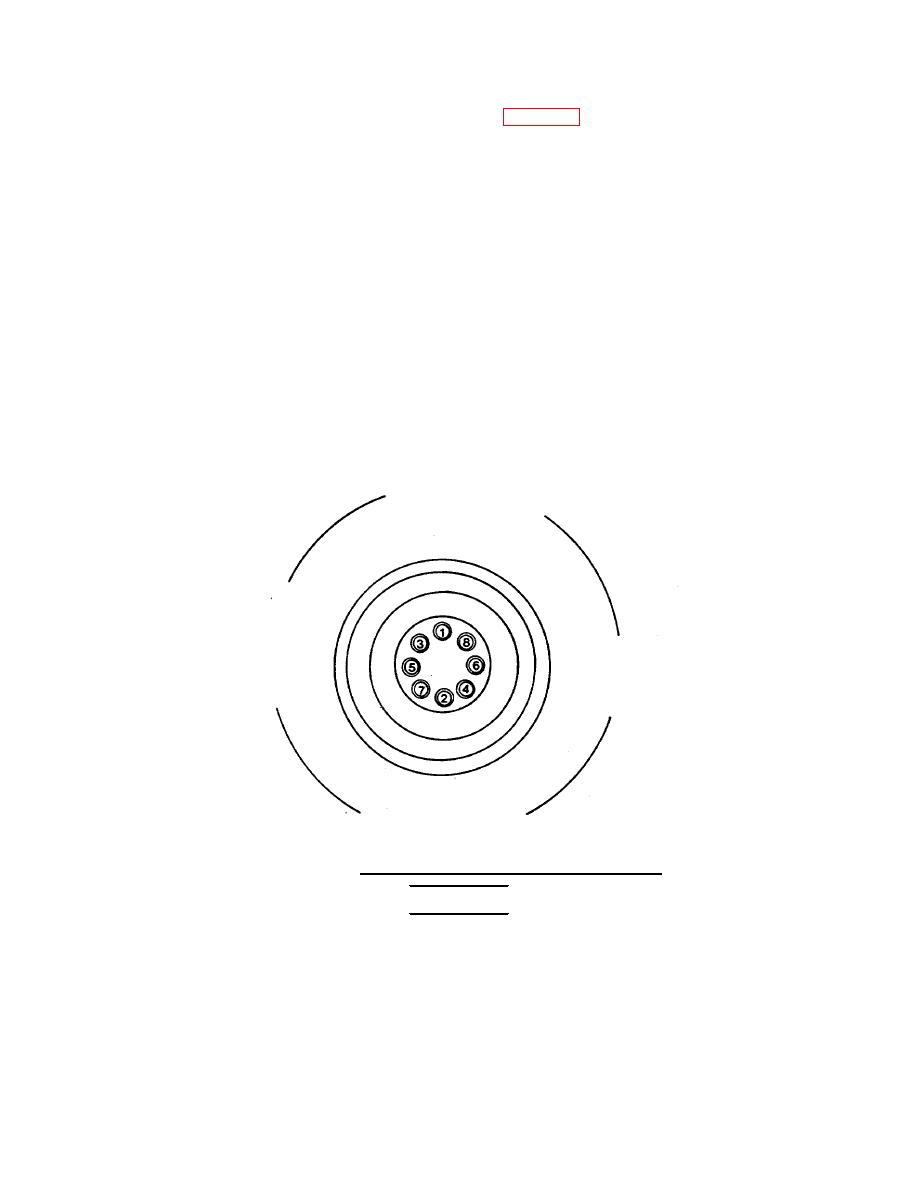

f. Install remaining bolts (1). Using the sequence in FIG. 4-44, torque bolts to 160 ft-lb (220 N m).

Advance bolts to 290 ft-lb (395 N ). Apply final torque of 410 ft-lb (555 N ).

m

m

CAUTION

Dampers are available with standard and high viscosity fluid

inside. If the damper has been replaced, verify the correct

damper is installed.

The vibration damper must be aligned correctly with the

crankshaft adapter. Incorrect alignment will cause the

valve and injector adjustment marks on the damper to be in

the wrong position.

The vibration damper is heavy. To avoid personal injury or

equipment damage, use a lifting sling or get assistance when

lifting the vibration damper.

g. Position the vibration damper (6) over the guide studs, engaging the adapter roll pin (7) and damper

receiving hole.

FIGURE 4-44. Tightening Sequence for Crankshaft Adapter.

WARNING

The capscrews (3) must be SAE grade 8. The washers (4) must

be hardened. If the wrong parts are used, the capscrews

could fail, allowing the damper to become loose and cause

personal injury.

h. Lubricate the washer (4) faces and capscrews (3) threads with clean engine lubricating oil. Torque the

capscrews (3) alternately and evenly to 155 ft-lb (210 N m).

i. Check the vibration damper for eccentricity and wobble as follows.

4-40

|

||

|

||