| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

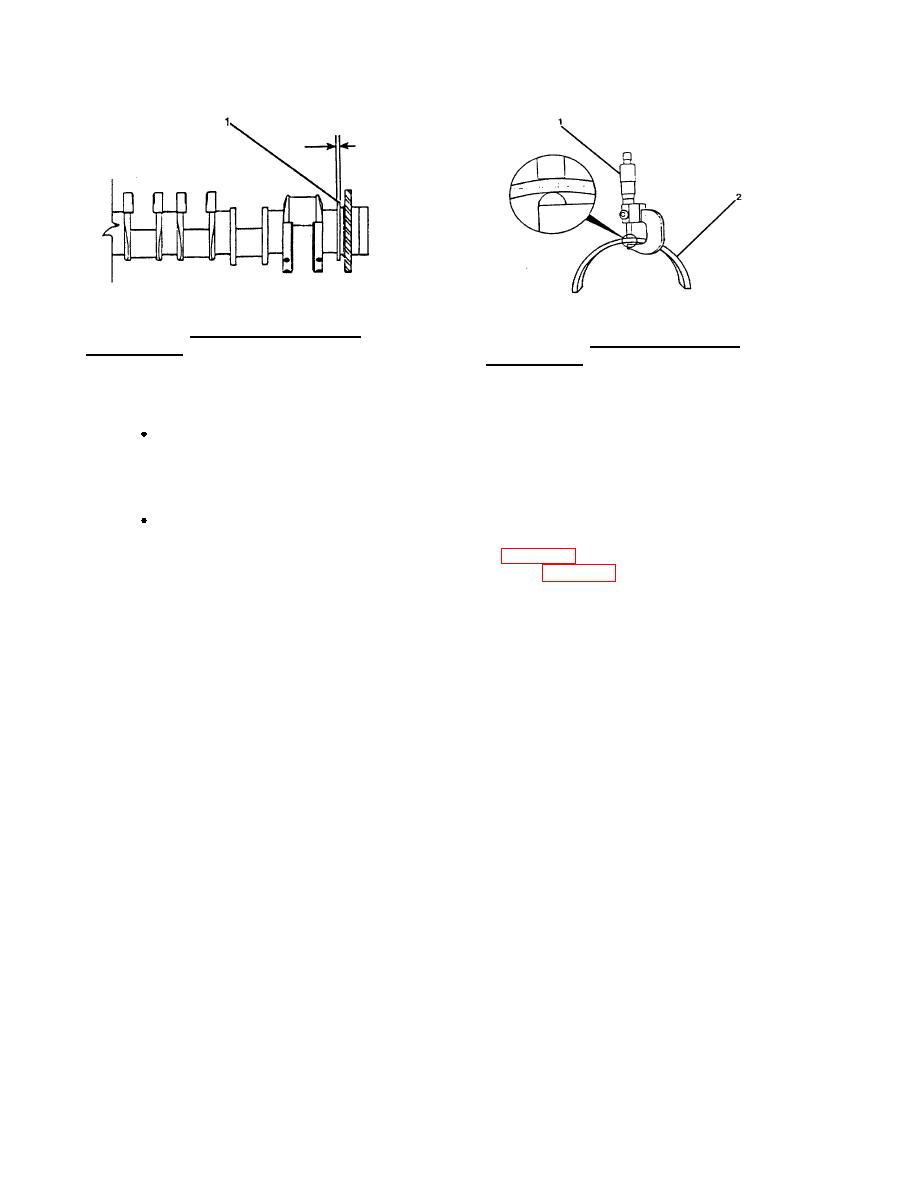

FIGURE 4-52. Crankshaft Thrust Flange

FIGURE 4-53. Bearing Shell (Sleeve)

Measurement.

Measurement.

NOTE

Do not scrape the bearing shells, or they will have to be lap filed, which increases the

oil clearances. A properly fitted bearing will appear dull gray after a reasonable period

of service, indicating it is running on an oil film. Bright spots indicate a metal-to-metal

contact and black spots indicate an excessive clearance.

Reground crankshafts or those used with undersize rod and main bearings and/or

oversized thrust rings should be marked so the correct bearing shells and thrust rings

can be installed in proper position. Markings (2, FIG. 4-54) for rod and main bearings

are on the front counterweight (1). Thrust ring size (2, FIG. 4-55), and location are on

the rear counterweight.

g.

Install the crankshaft gear if removed.

(1)

Install the key in the shaft.

(2)

Heat the gear in a preheated oven at 400 (205 ) for a minimum of one hour.

F

C

(3)

Lubricate the flange with high pressure grease. Install the gear onto the shaft.

4-47

|

||

|

||