| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

(5)

Repeat steps (3) and (4) until piston is thorou hly clean.

g

WARNING

Use protective clothing to prevent personal injury from steam burns.

(6)

Use steam to rinse the solvent from the piston. Dry with compressed air.

(7)

Check piston ring grooves. Replace piston if there is a visible ridge in the back of the groove or if a lip

has formed on the outside diameter of the groove.

(8)

Check piston for scratches, scuffing or other damage. Replace piston if damaged.

NOTE

Piston measurements must be done when the piston is a room temperature of approximately 70

F

(21 ).

C

(9)

Measure the inside diameter of the piston pin bore at several points. Replace piston if diameter is not

between 2.3985 inch (60.922 mm) and 2.3989 inch (60.932 mm).

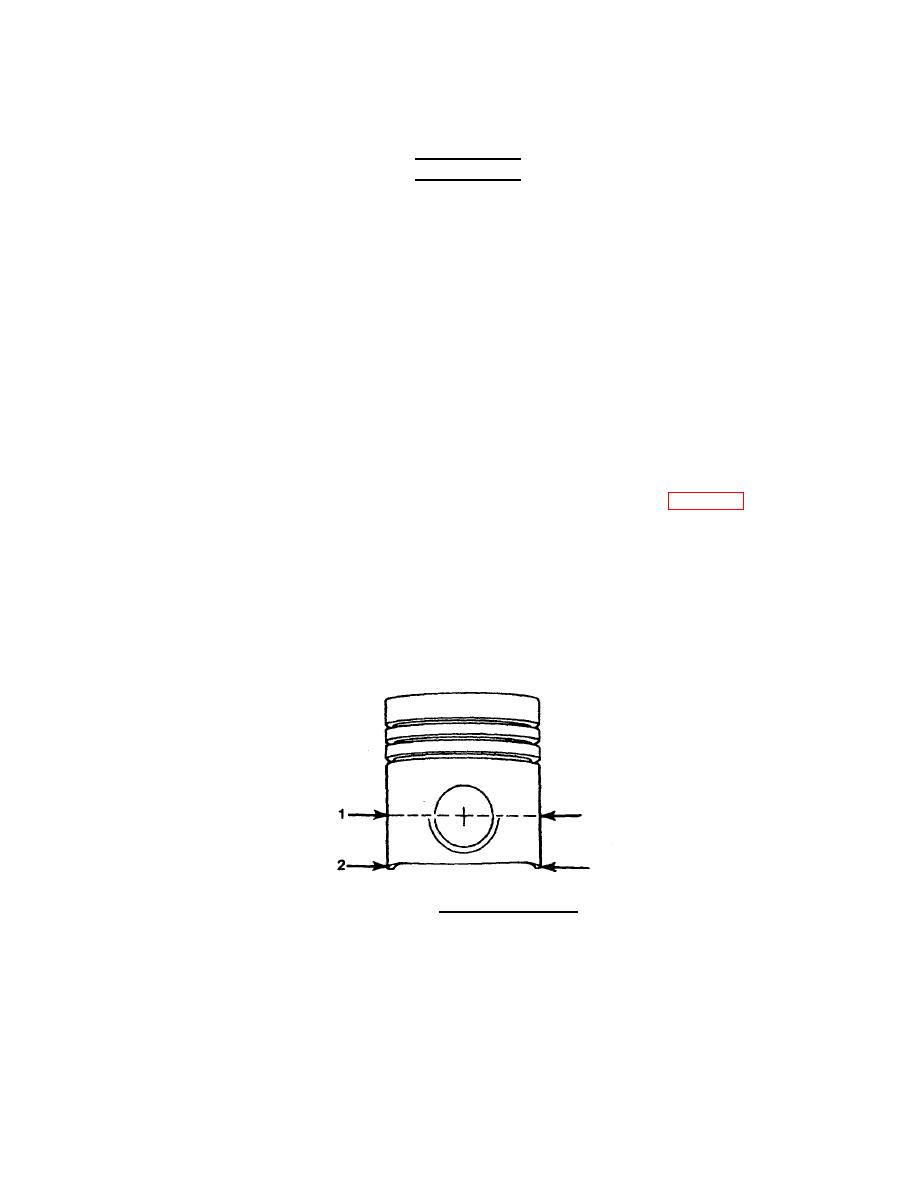

(10) Measure the outside diameter of the piston at the centerline of the pin bore (1, FIG. 4-70) and at 1 inch

(25 mm) from the bottom (2). Replace piston if measurements are not as follows:

Location (1): 6.2380 inch (158.445 mm) to 6.2390 inch (158.471 mm)

Location (2): 6.2378 inch (158.440 mm) to 6.2402 inch (158501 mm)

.

(11) Use dye penetration method, check for cracks on the top of the piston and within the piston pin ring bore.

Replace piston if cracks are found.

FIGURE 4-70. Piston Measurement.

4-74

|

||

|

||