| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-1

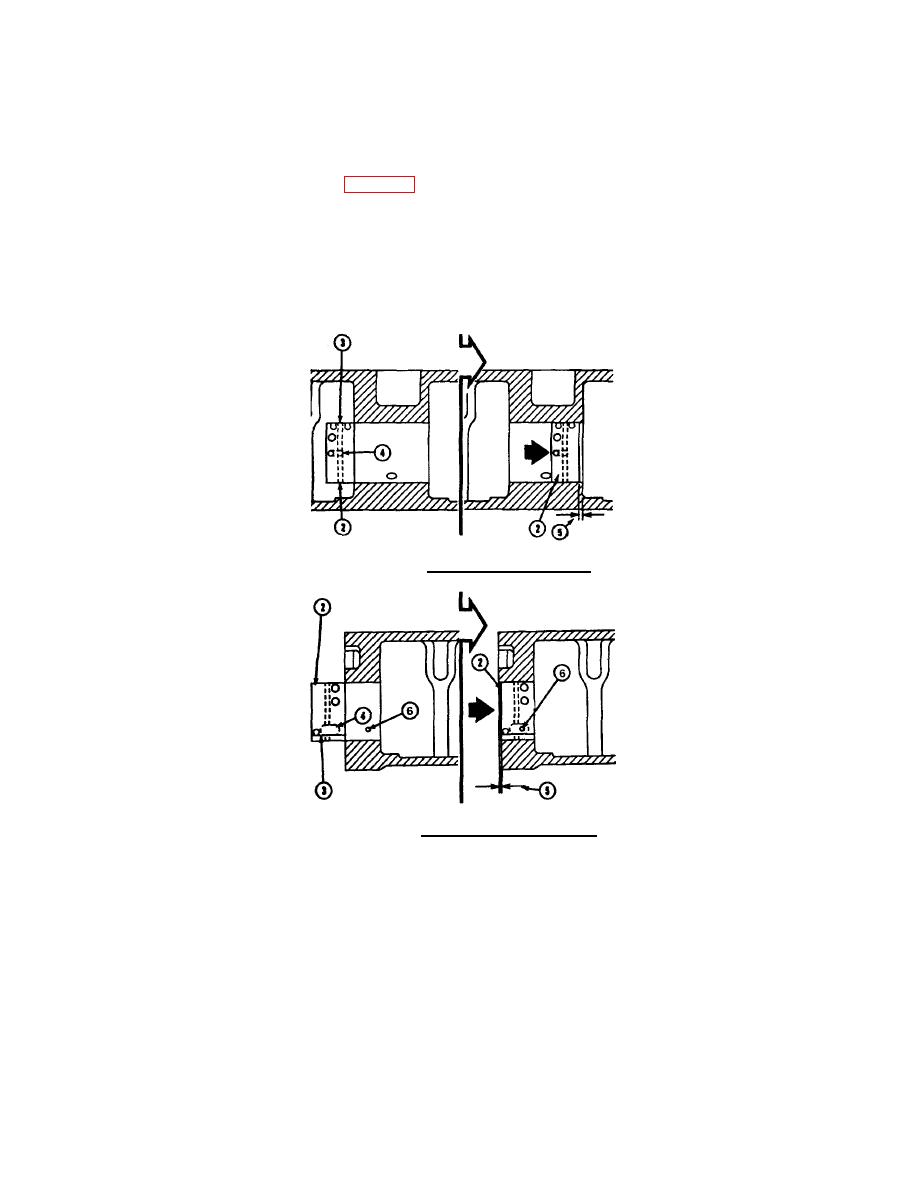

(2) Use drive assembly to push bushingthrough the bore. Ensure bushing is even with or no

more than 1/16 inch (1.6 mm) below the surface of the block web (5).

(3) Install second bushing using same procedure as above.

(4) Position bushing (2, FIG. 4-88) so that elongated hole in bushing (4) is in line with oil

hole in block (6). Ensure oil holes in bushing are nearest to cylinder block and clinch join (3)

is pointed toward outboard side of bore.

(5) Use drive assembly to push bearing in bore until it is even with or nomore than 1/16 inch

(1.6 mm) below the surface of the block web (5).

(6) Ensure oil hole in block (6) is open and clean and aligned with elongated hole in bushing (4).

FIGURE 4-87. Two Bushing Installation.

FIGURE 4-88. Single Bushing Installation.

b.

Install expansion plugs, expansion shields, pipe plugs, and dowels.

(1) Apply sealant to outside of expansion plug, and expansion shields (15 and 14, FIG. 4-

75). Use cup plug driver to install.

(2) Install pipe plugs (16, 17, and 26).

4-99

|

||

|

||