| Tweet |

Custom Search

|

|

|

||

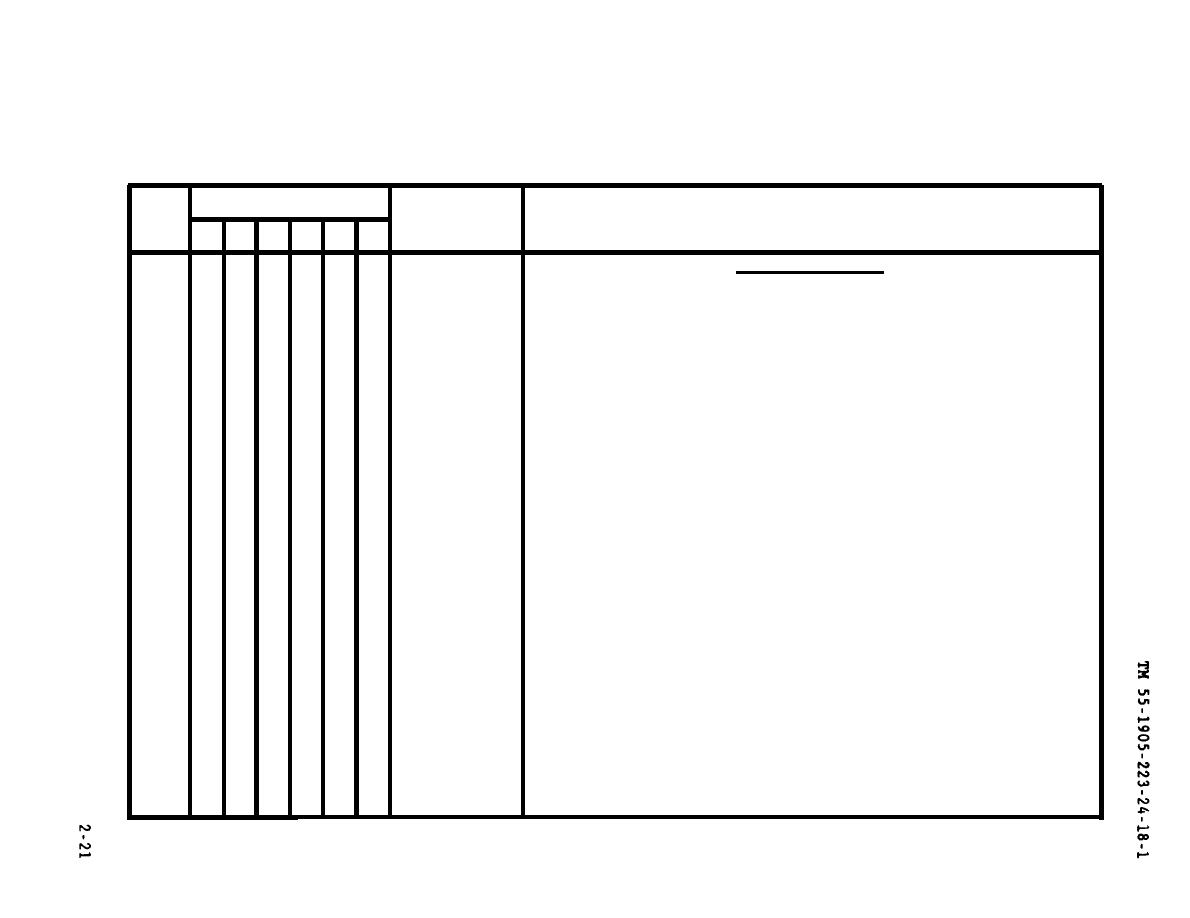

Preventive Maintenance Checks and Services - Cont.

Table 2-1.

Q - Quarterly

S - Semiannually

A - Annually

D - Daily W - Weekly M - Monthly

Items To Be

Interval

Item

Procedures

Inspected/

No.

D

W

M

Q

S

A

Serviced

CONTROLS SYSTEMS

q

a. Inspection.

Control Sub-

47

systems

(1)

Operate the systems, observe the function for

normal operational, Ahead and Astern. Recommend

Control

system supply pressure, 120 psi.

Station

(Pilothouse)

(2) During operation , check for air leaks at tubing

Control

fittings, valves, and actuator seals by using

Station

liquid leak detector. Assure all tubing is

(Engine Room)

secured and insulated from excessive vibration,

Gear Mate

check all flexible hoses for cracking, aging, or

Control

chafing.

System

Governor

(3)

With the system actuated Ahead, inspect for the

Actuator Air-

following, then check again while actuated

Prep System

Astern.

Gauge Shuttle

Valve 4-Way

(a)

The 3-position gear actuator cylinder

Transfer

should move freely without binding or

Valve 3-Way

twisting. The same is true for the

Transfer

governor actuator. Check all linkages and

Valve Shaft

adjustments for correct alignment.

Brake Panel

Ball Valve

Check all pivot points for freedom of

(b)

Governor

movement, excessive wear and corrosion.

Override

Roller-

Check valve indicator pins or stem

(c)

Operated

positions and ensure all are in proper

Valve 4-Way

sequence. (Refer to trouble locator

Valve

guide.)

Cylinder

|

||

|

||