| Tweet |

Custom Search

|

|

|

||

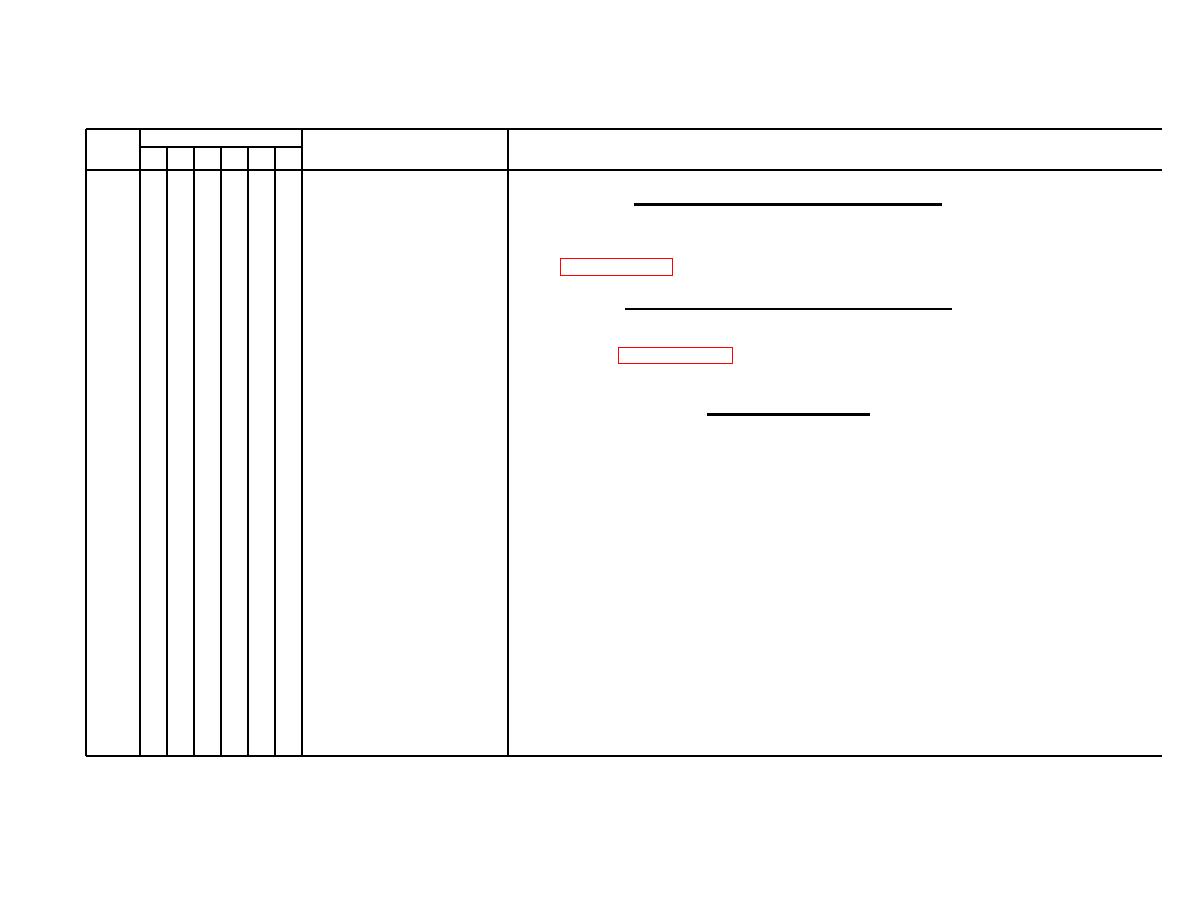

TM 55-1905-223-24-18-2

Table 3-1. Preventive Maintenance Checks and Services

D - Daily

W - Weekly

M -Monthly

Q - Quarterly

S - Semiannually

A - Annually

Item

Intervals

Items To Be

No.

DWMQS

A

Inspected/Serviced

Procedures

14

Tank Level

TANK LEVEL INDICATOR SYSTEM - CONT

Indicator

System

Inspect for corrosion, tightness, and evidence of

Potenti-

burning. Replace defective potentiometers as specified

ometers

in paragraphs 3-41 and 3-42.

NAVIGATION SIGNALS AND SEARCHLIGHTS

XENON

15

Check reading. Lamp should be replaced every 1500-1600

Searchlight

hours. See paragraph 3-46.

Elapsed Time

Indicator

CONTROLS SYSTEMS

NOTE: DONE PRIOR TO GETTlNG UNDERWAY

16

Steering

Control

NOTE

System

These tests and adjustments should be

done prior to getting underway and

in the order listed.

a. Visual Wiring Check. Check wiring and component

mounting for possible causes of damage from vibration,

chafing, strain, overheating, and short circuits from

loose wires.

b. Power Source Check. Check power leads for correct

polarity and voltage using a voltmeter.

c.

Gyrocompass Alignment and Calibration.

d. Alignment. After the gyrocompass is restarted, adjust

the gyro interface course reference dial to align with

3-6

|

||

|

||