| Tweet |

Custom Search

|

|

|

||

TM 55-1905-223-24-18-2

(2) Remove capscrews (6 and 8), with washers and remove side plate (7) from brake element.

b. Remove friction shoe assemblies.

(1) Mark each friction shoe assembly (12) backing plate and its position on brake element rim

(9) to ensure assembly in same position.

and flat release spring (14) will come out with the friction shoe assembly as a unit.

shoe assembly.

c. Remove rubber actuating tube.

(1) Disconnect air tubing from IN port of quick exhaust safety release valve (4).

(2) Remove quick exhaust safety release valve (4) from straight adapter (5).

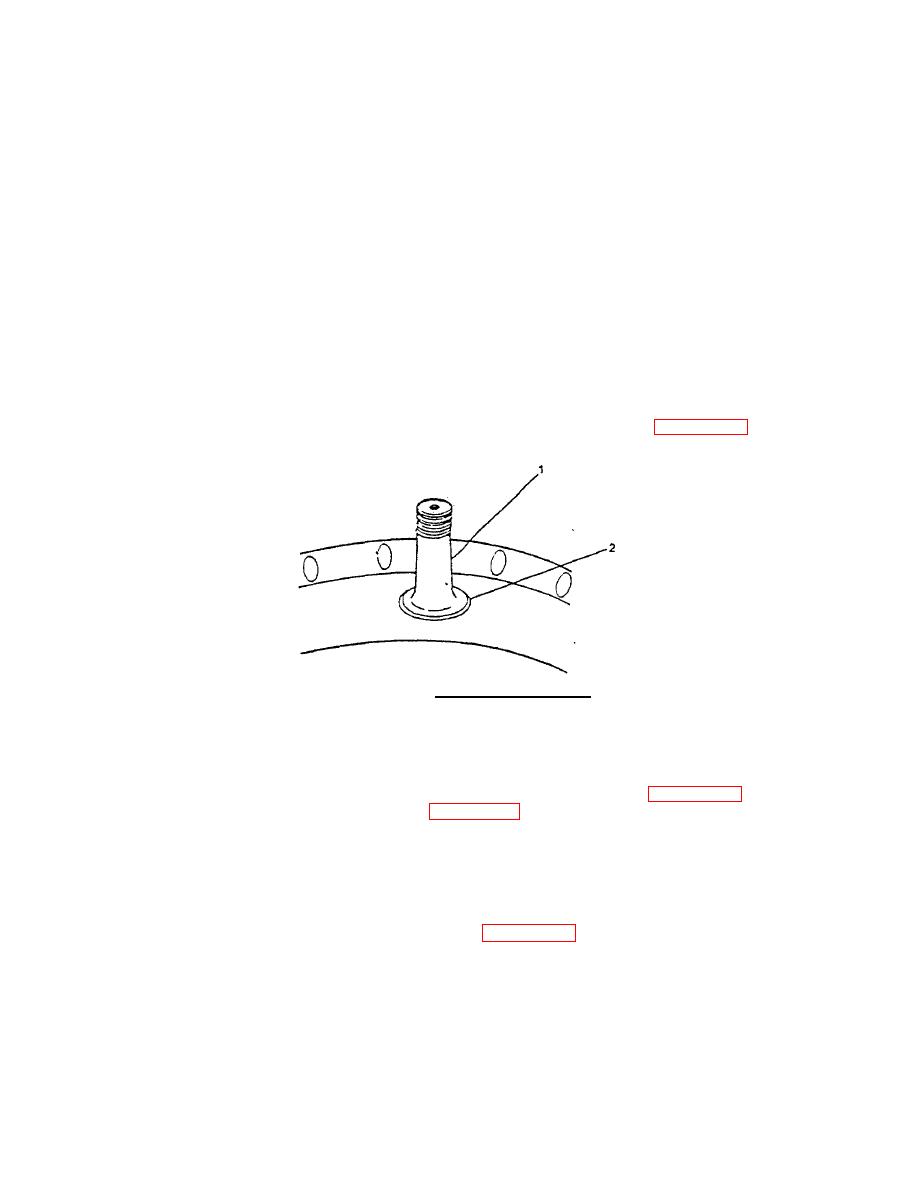

(3) Remove straight adapter (5) from rubber actuating tube valve (1), Figure 3-192 .

Rubber Actuating Tube.

(4) Remove snap ring (2) securing rubber actuating tube valve (1) to the rim. Replacement

snap ring is furnished with replacement tube.

(5) Using smooth bar, insert bar between rubber actuating tube (11, Figure 3-191) and rim (9)

and force actuating tube valve (1, Figure 3-192) to clear hole in rim and pull tube out of rim.

REPAIR

a. Inspect friction shoe assembly.

(1) Inspect each friction shoe assembly (12, Figure 3-191) for broken or cracked flat release

springs (14) and torque bars (13). Replace defective springs and torque bars with new ones.

3-650

|

||

|

||